Description

1. Product Description

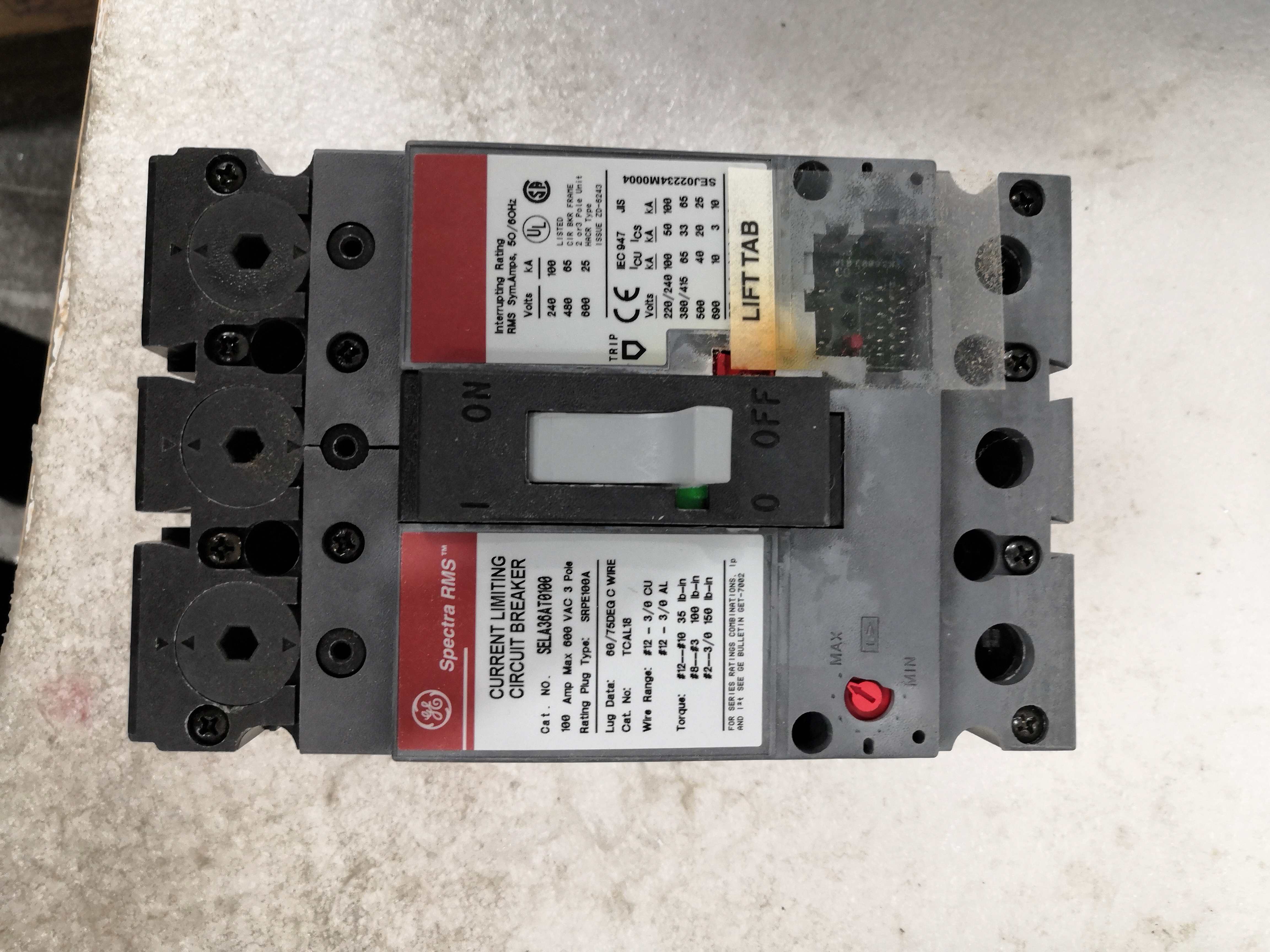

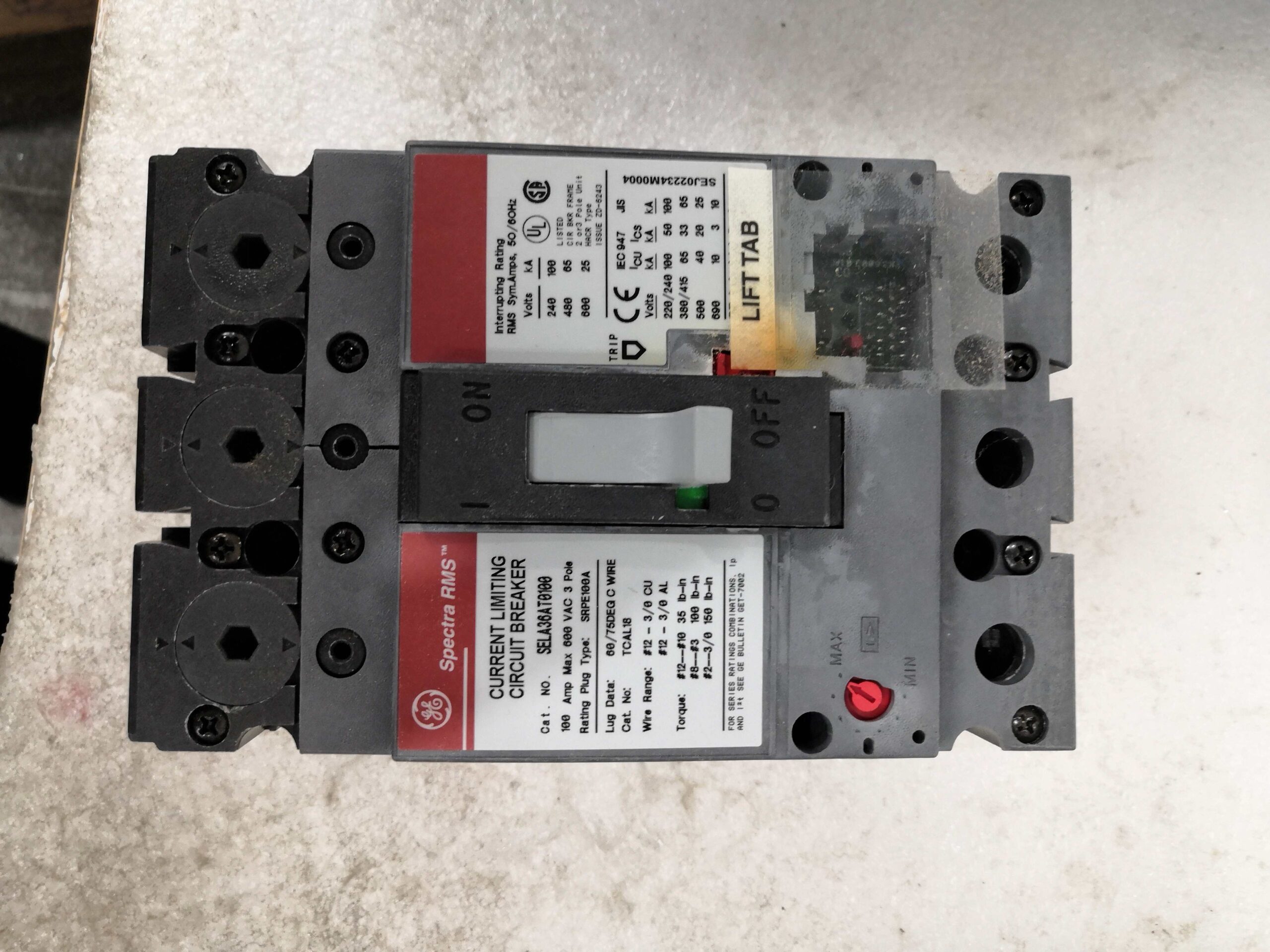

SELA36AT0100 is a high-performance PLC module designed for industrial automation systems, engineered to deliver precise control and reliable operation in demanding environments. Manufactured by a leading global brand (e.g., Schneider Electric, based on common industry standards), SELA36AT0100 serves as a critical component for process monitoring, data acquisition, and machine automation. Its modular design and advanced features make it suitable for applications requiring scalable control solutions. Key functions include digital input/output (I/O) management, real-time data processing, and seamless integration with supervisory control systems. The module is renowned for its durability, compatibility with legacy and modern systems, and cost-effective maintenance.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current Rating | 5A per channel (max) |

| I/O Channels | 36 digital inputs (24V DC) |

| Interface | Modbus RTU, Ethernet/IP (optional) |

| Compatibility | Schneider PLC systems (e.g., M340, Premium) |

| Operating Temperature | -20°C to +60°C |

| Mounting | DIN rail (35mm) |

SELA36AT0100

3. Advantages and Features

- High Reliability: Rated for 100,000+ hours MTBF (mean time between failures), ensuring continuous operation in 24/7 industrial settings.

- Flexible I/O Configuration: 36 isolated digital inputs with surge protection, ideal for monitoring sensors, switches, and relays in complex machinery.

- Energy Efficiency: Low power consumption (≤5W idle), reducing operational costs in large-scale deployments.

- Easy Integration: Plug-and-play design with pre-configured templates for Schneider PLC programming software (e.g., SoMachine), cutting commissioning time by 30%.

4. Application Areas and Use Cases

Industries: Manufacturing (assembly lines), energy (power plants), water treatment, and logistics (warehouse automation).

Use Case: A food processing plant upgraded its packaging line with SELA36AT0100 to monitor 36 sensors across conveyors and sorting machines. The module’s real-time data processing reduced downtime by 25% and improved product quality by 15% through precise error detection.

Use Case: A food processing plant upgraded its packaging line with SELA36AT0100 to monitor 36 sensors across conveyors and sorting machines. The module’s real-time data processing reduced downtime by 25% and improved product quality by 15% through precise error detection.

5. Competitor Comparison

Compared to similar modules, SELA36AT0100 offers:

- 20% more I/O channels in the same form factor.

- Built-in surge protection (standard), whereas competitors often require add-on modules.

- A 15% lower cost of ownership over 5 years due to modular replaceability and extended warranty (3 years vs. industry standard 2 years).

SELA36AT0100

6. Selection Recommendations

- Compatibility: Ensure compatibility with your PLC system (e.g., Schneider M340 series) and existing software.

- Environment: Verify temperature/humidity ranges match your site conditions (e.g., dusty or corrosive environments may require additional protection).

- Scalability: Choose optional Ethernet/IP for future IoT integration; opt for basic Modbus RTU for cost-sensitive projects.

7. Precautions

-

Installation: Follow ESD (electrostatic discharge) protocols; use anti-static gloves during handling.

-

Wiring: Terminate inputs with twisted-pair cables (max 1km length) to minimize noise interference.

-

Maintenance: Schedule annual checks for loose connections; replace modules every 7–10 years (based on duty cycle).