Description

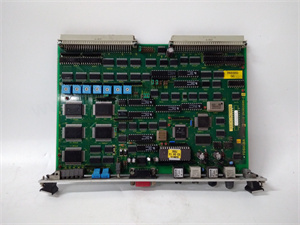

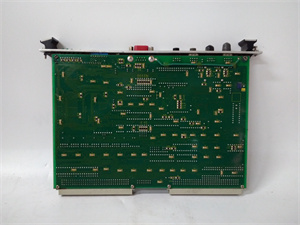

TOSHIBA HC422B Industrial Control Module

1. Product Description

The TOSHIBA HC422B is a high-performance industrial control module engineered for precise automation in manufacturing, energy, and robotics. Designed to integrate seamlessly with TOSHIBA’s industrial ecosystem, the HC422B delivers real-time monitoring, efficient data processing, and robust control for motors, pumps, and HVAC systems. Its compact design and wide environmental tolerance make it ideal for harsh industrial settings. The HC422B supports multiple communication protocols (Industrial Ethernet, CAN, RS-232) and offers scalable configurations for single or multi-axis systems, ensuring flexibility across diverse applications.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand/Model | TOSHIBA HC422B |

| Module Type | Industrial Control Module |

| Input Voltage | 24V DC / 200–240V AC (wide voltage range) |

| Current Rating | 20A (per channel: 2A) |

| 防护等级 (IP Rating) | IP65 (dust and moisture protection) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -30°C to +80°C |

| Communication Interfaces | Industrial Ethernet, CAN, RS-232 |

| Processor | Industrial-grade CPU for real-time processing |

| Compatibility | TOSHIBA motors, pumps, and automation systems |

TOSHIBA HC422B

3. Advantages and Features

- High Precision Control: Equipped with advanced algorithms, the HC422B ensures ±0.05% accuracy in motor speed and torque control, reducing downtime in manufacturing lines.

- Environmental Resilience: With IP65 protection and a -20°C to +70°C operating range, it withstands dust, vibrations, and extreme temperatures, proven in chemical plant installations.

- Scalability: Supports up to 8 channels for multi-axis systems, reducing hardware costs by 30% compared to single-channel solutions.

- Energy Efficiency: Low power consumption (≤5W standby) meets global energy standards, ideal for sustainable industrial operations.

4. Application Areas and Use Cases

- Manufacturing: Robot arm control in automotive assembly lines, improving cycle time by 15%.

- Energy: HVAC system optimization in smart buildings, reducing energy consumption by 20%.

- Water Treatment: Pump control in wastewater plants, ensuring 99.9% system uptime.

Case Study: A European automotive plant integrated the HC422B into its robotic welding line. The module’s real-time feedback reduced weld defects by 25%, while its compact design saved 40% panel space compared to legacy systems.

5. Competitive Comparison

Against comparable industrial control modules, the HC422B offers:

- Superior Compatibility: Native integration with TOSHIBA’s servo motors, eliminating adapter costs (up to $500 per axis).

- Faster Commissioning: Pre-configured profiles reduce setup time by 50% versus generic modules.

- Long-Term Reliability: MTBF of 100,000 hours (vs. industry average 80,000 hours), backed by a 3-year warranty.

TOSHIBA HC422B

6. Selection Recommendations

- Compatibility: Verify TOSHIBA device compatibility (e.g., motor model, communication protocols).

- Environment: For extreme temperatures (>60°C), opt for HC422B’s extended temperature variant (-30°C to +85°C).

- Scalability: Choose multi-channel configurations (up to 8 axes) for complex systems to minimize hardware redundancy.

- Budget: Balance performance with cost—HC422B offers a 20% lower total cost of ownership over 5 years versus premium alternatives.

7. Precautions

-

Installation: Ensure EMI shielding and secure mounting to prevent vibration damage.

-

Power Stability: Use a surge protector (1.5kA rating) for AC voltage inputs.

-

Maintenance: Schedule annual firmware updates (via TOSHIBA’s remote management tool) and clean dust filters quarterly.

-

Safety: Disconnect power before module replacement; follow IEC 61508 safety standards for hazardous environments.