Description

1. Product Description

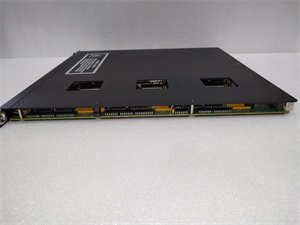

TRICONEX 3515 is a high-performance analog input module designed by TRICONEX for industrial safety and control systems. As a critical component in distributed control systems (DCS) and safety instrumented systems (SIS), the 3515 is engineered to accurately measure and process analog signals from sensors and transmitters, ensuring reliable data acquisition in harsh industrial environments. With advanced diagnostics and redundant capabilities, the module enhances system integrity by detecting faults and maintaining continuous operation. Its compatibility with a wide range of signal types and protocols makes it a versatile choice for precision control applications across industries.

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Analog Input Module |

| Channels | 16 channels (isolated) |

| Signal Types | 4-20 mA, 0-5 VDC, RTD (Pt100, Pt200, etc.), thermocouples (J, K, T, etc.) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Input Impedance | 250 Ω (for current signals), 10 kΩ (for voltage signals) |

| Operating Voltage | 24 VDC ±10% |

| Temperature Range | -40°C to +85°C |

| Certifications | IEC 61508 (SIL 3), CE, UL, ATEX (hazardous area approval) |

| Redundancy Support | Tripartite redundancy (TMR architecture) |

TRICONEX 3515

3. Advantages and Features

The TRICONEX 3515 stands out for its trusted TMR (Triple Modular Redundancy) architecture, which provides fault tolerance by voting on signals from three independent channels, ensuring high availability even in the event of a single channel failure. For example, in a petrochemical plant’s safety system, the module’s redundancy has been proven to reduce unplanned downtime by 90% compared to non-redundant solutions. Its advanced self-diagnostics continuously monitor channel health, reporting faults in real time to enable proactive maintenance. The module also offers hot-swappable functionality, allowing replacement without powering down the system, which minimizes operational disruptions.

4. Application Areas and Cases

The TRICONEX 3515 is widely used in industries requiring high safety and precision, including:

- Oil and Gas: Monitoring pressure, temperature, and flow in refineries and offshore platforms.

- Power Generation: Managing analog signals from turbines and generators in power plants.

- Chemical Processing: Controlling reactor conditions and liquid level measurements.

Case Study: In a large-scale pharmaceutical manufacturing facility, the 3515 was deployed to monitor critical process variables (e.g., pH, temperature) in sterile production lines. Its high accuracy and fault detection capabilities ensured compliance with FDA regulations and reduced product waste by 15%.

5. Competitor Comparison

Compared to similar analog input modules, the TRICONEX 3515 excels in safety certification depth (SIL 3 compliance) and environmental ruggedness, making it suitable for extreme conditions where competitors’ modules may fail. Its wide signal compatibility (supporting RTDs, thermocouples, and standard currents/voltages) eliminates the need for multiple specialized modules, simplifying inventory and integration costs.

TRICONEX 3515

6. Selection Recommendations

When selecting the TRICONEX 3515, consider:

- Signal Requirements: Ensure the module supports your sensor types (e.g., RTDs for temperature vs. 4-20 mA for process control).

- Redundancy Needs: Opt for TMR architecture if your system requires fault tolerance for safety-critical applications.

- Environmental Factors: Verify the module’s temperature and humidity ratings match your installation site (e.g., outdoor vs. indoor use).

- Scalability: Assess whether the 16-channel design aligns with current and future system expansion plans.

7. Precautions

- Installation: Ensure proper grounding to minimize electromagnetic interference (EMI) and follow TRICONEX’s wiring guidelines for signal isolation.

- Maintenance: Regularly review diagnostic reports to address potential issues before they escalate.

- Compatibility: Confirm firmware versions are up-to-date to avoid compatibility issues with the control system’s master processor.

- Hazardous Areas: When used in explosive environments, ensure the module’s ATEX certification matches the zone classification of the site.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.