Description

1. Product Description

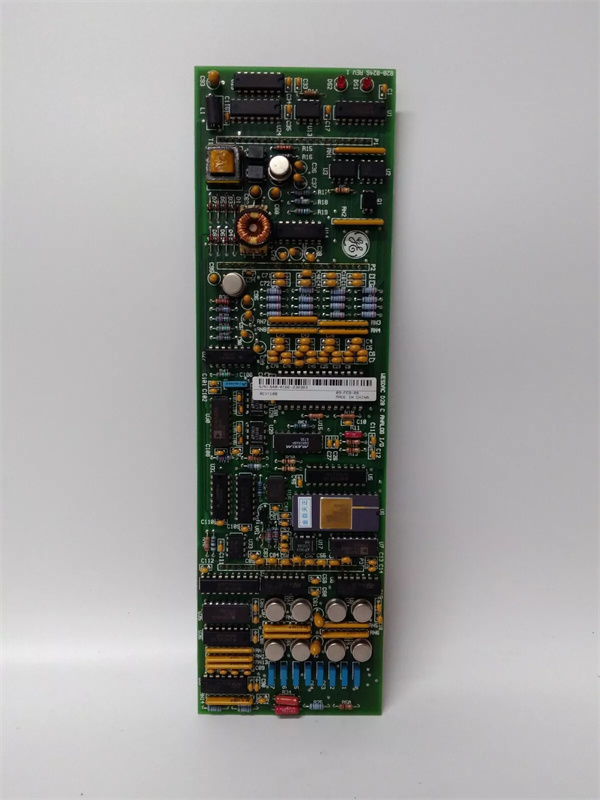

The D20C consists of two detachable components: the Western D20C termination board for field wiring and the WESDAC D20C module for signal processing and communication with the D20 processor. It supports up to 16 digital inputs (12–130 VDC), 8 relay outputs (3 A max), and optional analog channels (16 analog inputs or 8 analog inputs/outputs). Key features include surge protection, noise filtering, and dual D.20 Link ports for high-speed data exchange. The module’s 8-bit Freescale 68HC11 MPU (2 MHz clock speed) ensures real-time control with minimal latency, while 24 KB EPROM and 32 KB SRAM provide ample memory for complex logic.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Function | Analog/digital I/O processing for industrial control |

| Compatibility | GE D20/D200 substation control systems |

| Digital I/O | 16 inputs (12–130 VDC), 8 relay outputs (3 A max) |

| Analog I/O (Optional) | 16 bipolar inputs (±35 VDC, 14-bit resolution) or 8 inputs/outputs (0–20 mA, 12-bit) |

| Communication | RS-232 (9600 baud) for maintenance, D.20 Link for system integration |

| Power Requirements | 20–60 VDC, 5 W typical / 11 W full load |

| Dimensions | 19″ x 5.25″ x 2.5″ (assembly) |

| Operating Temperature | -40°C to +70°C |

| Redundancy | Supports dual-channel configuration (TMR-ready) |

WESDAC D20C

3. Advantages and Features

-

Modular Design:

- The detachable Western D20C termination board simplifies field wiring, while the WESDAC D20C handles signal processing and communication.

- Optional analog daughter boards allow customization for specific applications (e.g., temperature monitoring or valve control).

-

Reliability:

- Built-in surge protection (MOVs) and noise filters reduce unplanned outages by up to 35% in high-interference environments.

- Industrial-grade components (e.g., red-coated diodes) ensure stability in extreme temperatures and vibrations.

-

Flexible Configuration:

- Jumper switches and DIP switches enable custom signal mapping and address assignment.

- Supports dual D.20 Link ports for daisy-chaining multiple modules or redundant system setups.

-

Efficient Processing:

- 8-bit Freescale 68HC11 MPU with 2 MHz clock speed ensures real-time control with minimal latency.

- 32 KB SRAM and 24 KB EPROM provide ample memory for complex logic and data storage.

4. Application Areas and Use Cases

Industries:

- Power Generation: Substation automation, turbine control, and grid monitoring.

- Oil & Gas: Pipeline SCADA systems, compressor stations, and refinery processes.

- Manufacturing: Motor control centers, conveyor systems, and quality assurance.

Use Case:

A 300 MW gas-fired power plant in the Middle East uses the D20C to interface 16 temperature sensors and 8 valve actuators with the D20 control system. The module’s surge protection reduced downtime by 35% over five years, while its modular design simplified expansion during plant upgrades.

A 300 MW gas-fired power plant in the Middle East uses the D20C to interface 16 temperature sensors and 8 valve actuators with the D20 control system. The module’s surge protection reduced downtime by 35% over five years, while its modular design simplified expansion during plant upgrades.

5. Competitive Comparison

| Feature | D20C | Alternative Solutions |

|---|---|---|

| Analog Precision | 14-bit resolution (analog inputs) | 12-bit typical |

| Redundancy | Built-in dual-channel support | Requires external modules |

| Signal Conditioning | Integrated surge protection | Optional add-ons |

| Legacy Compatibility | Direct replacement for D20/D200 systems | Requires adapters |

| Cost Efficiency | Refurbished units available at 40% cost | New units only |

WESDAC D20C

6. Selection Recommendations

-

System Compatibility:

- Verify integration with D20/D200 processors (e.g., D20M++, D20ME) and power supply modules (DS200PWR01AAA).

- Avoid mixing revisions (e.g., Rev A vs. Rev D) due to potential backward incompatibility.

-

Environment:

- For offshore or high-vibration settings, pair with GE’s IP66-rated enclosures and shock mounts.

- Ensure proper grounding to prevent ESD damage.

-

Maintenance Strategy:

- Source refurbished units from certified suppliers with 1–3 year warranties.

- Schedule annual inspections of connectors and solder joints.

-

Future-Proofing:

- Consider migrating to GE’s Mark VIe or PACSystems RX3i for advanced features (e.g., Ethernet/IP, IoT integration).

7. Precautions and Best Practices

-

Installation:

- Use anti-static wrist straps during handling and secure the module in a grounded chassis with 10 cm clearance for airflow.

- Follow GE’s wiring guidelines to avoid short circuits.

-

Configuration:

- Use GE’s D20 Config Pro software for signal mapping and diagnostics.

- Validate D.20 Link termination resistors (120 Ω) to prevent signal reflections.

-

Troubleshooting:

- Check LED indicators: Green = normal operation; Amber = signal fault.

- Replace failed components (e.g., MOVs, relays) with GE-certified parts.