Description

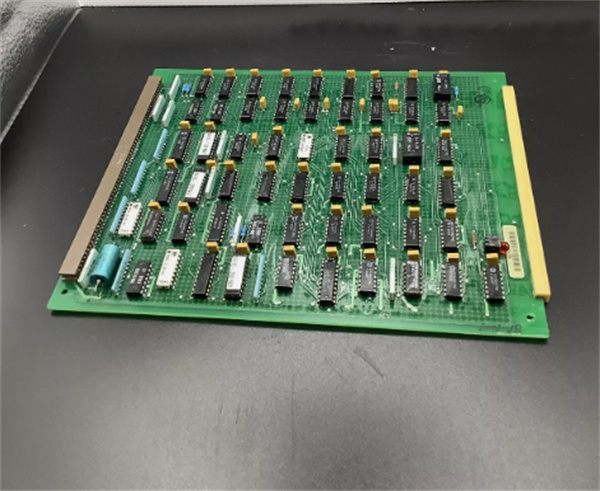

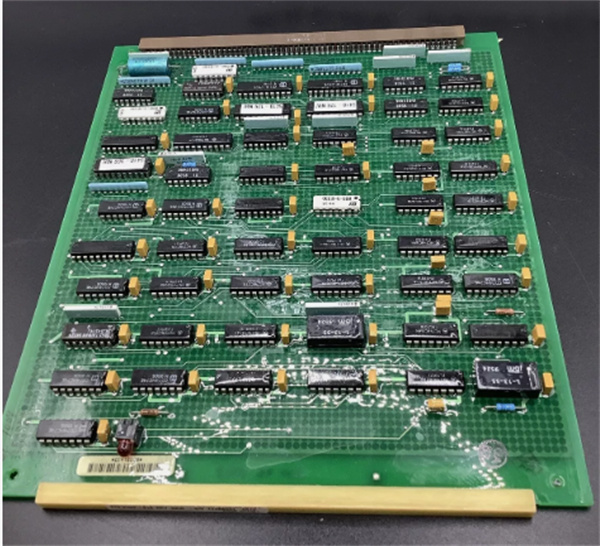

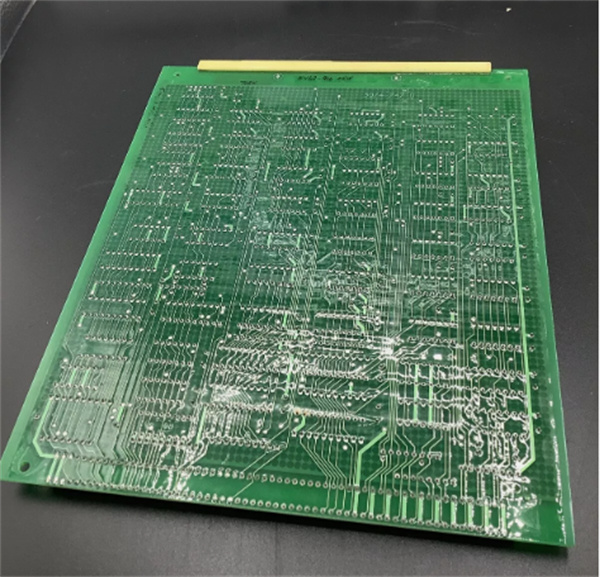

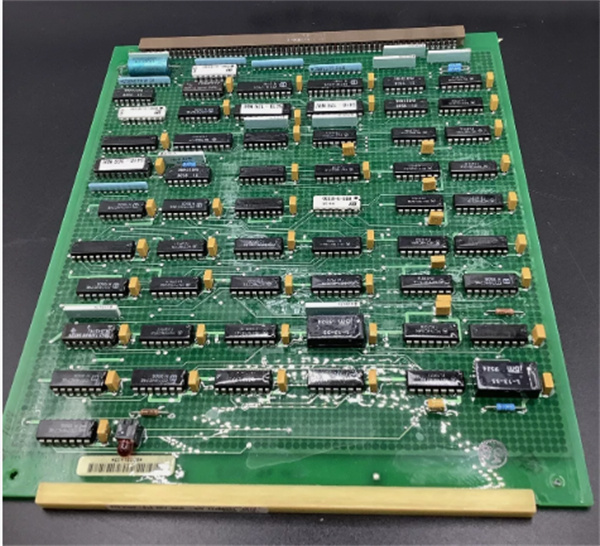

Woodward 5462-916 FTC DCS II Electronic Module

1. Product Description

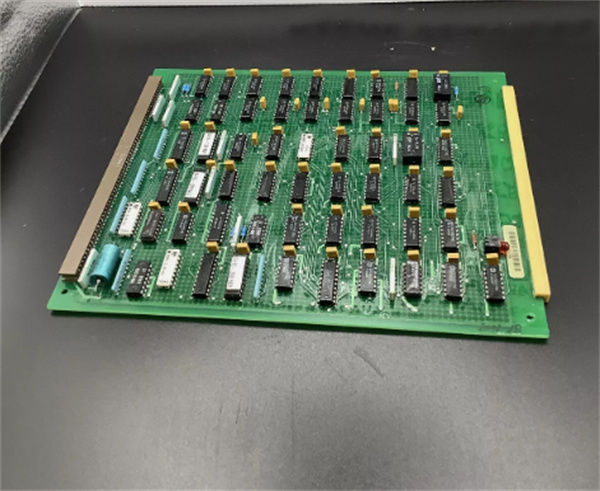

The Woodward 5462-916 is an advanced industrial digital control module designed for automation systems, belonging to the FTC DCS II series. It integrates multi-channel control, communication, and diagnostic capabilities, making it suitable for complex industrial environments such as power generation, manufacturing, and chemical processing. With compatibility with PLC and DCS systems, the 5462-916 ensures precise process monitoring and control. Its robust design supports high reliability in harsh conditions, while modular architecture allows seamless integration with existing systems.

The Woodward 5462-916 is an advanced industrial digital control module designed for automation systems, belonging to the FTC DCS II series. It integrates multi-channel control, communication, and diagnostic capabilities, making it suitable for complex industrial environments such as power generation, manufacturing, and chemical processing. With compatibility with PLC and DCS systems, the 5462-916 ensures precise process monitoring and control. Its robust design supports high reliability in harsh conditions, while modular architecture allows seamless integration with existing systems.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | FTC DCS II Electronic Module |

| Input/Output | Multi-channel I/O control (specific channels vary by application) |

| Power Supply | 10–32 VDC (transient voltage range: 6–32 VDC) |

| Maximum Current | Coil RMS: 4 A (peak: 7.5 A) |

| Communication Protocols | RS-232, RS-485, Ethernet (optional) |

| Dimensions | 22.8 cm × 19.2 cm × 1 cm |

| Weight | 0.28 kg |

| Operating Temperature | -40°C to +85°C (industrial-grade tolerance) |

| Certifications | CE, ISO compliance (manufacturer-dependent) |

WOODWARD 5462-916

3. Advantages and Features

- Wide Voltage Range: Operates reliably across 10–32 VDC, reducing compatibility issues in diverse power environments.

- High Precision Control: Supports critical speed avoidance, auto-start sequences, and valve limiting for optimized performance.

- Enhanced Security: Password-protected programming prevents unauthorized modifications.

- Durable Design: IP65-rated enclosure (optional) and rugged components resist vibrations, shocks, and extreme temperatures.

- Real-Time Diagnostics: Continuous monitoring of system health with fault alerts and performance analytics.

4. Application Areas and Use Cases

- Energy Sector: Used in gas turbines and generators for load sharing and speed control.

- Manufacturing: Manages robotic assembly lines and conveyor systems in automotive plants.

- Chemical Processing: Controls pumps and reactors in petrochemical facilities.

- Transportation: Integrates with test benches for vehicle powertrain validation.

Example Case: A power plant in Europe reduced downtime by 20% using the 5462-916 to monitor turbine performance, enabling predictive maintenance and minimizing unexpected failures.

5. Competitor Comparison

Compared to similar modules, the 5462-916 offers:

Compared to similar modules, the 5462-916 offers:

- A broader voltage range (10–32 VDC vs. typical 24 VDC-only options).

- Faster response times (≤50 ms) for real-time control in dynamic systems.

- Higher current capacity (4 A RMS) for driving heavy-duty actuators.

WOODWARD 5462-916

6. Selection Recommendations

- Compatibility: Verify communication protocols (e.g., Modbus RTU) with existing PLC/DCS systems.

- Environment: Choose IP65-rated variants for dusty or wet environments.

- Scalability: Opt for modular configurations if future expansion is planned.

- Budget: Balance cost with long-term reliability; the 5462-916 offers a 3-year MTBF (mean time between failures) compared to industry averages of 2–2.5 years.

7. Precautions

- Installation: Follow wiring diagrams to avoid short circuits. Use shielded cables for signal lines to prevent interference.

- Maintenance: Schedule annual inspections to clean connectors and update firmware.

- Safety: Disconnect power before servicing. Ensure compliance with NEC/CE safety standards.