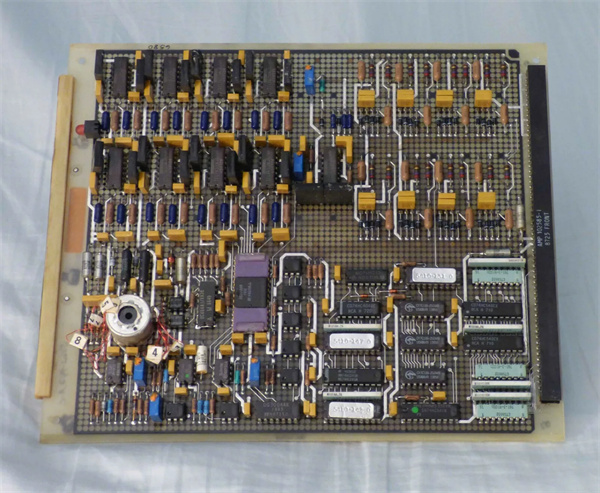

Description

WOODWARD 5462-948 T/C Card 8 Channel

1. Product Description

The WOODWARD 5462-948 is a high-precision temperature control module designed for industrial applications requiring reliable thermocouple (T/C) monitoring. With 8 isolated channels, it supports multiple thermocouple types (e.g., J, K, T, E) and integrates seamlessly with Woodward’s 505e, 505c, and NetCon control systems. Ideal for harsh environments, this module ensures real-time temperature data processing, enabling precise adjustments in machinery such as turbines, engines, and industrial equipment. Its compact design and robust construction make it a critical component for industries demanding accuracy and durability.

The WOODWARD 5462-948 is a high-precision temperature control module designed for industrial applications requiring reliable thermocouple (T/C) monitoring. With 8 isolated channels, it supports multiple thermocouple types (e.g., J, K, T, E) and integrates seamlessly with Woodward’s 505e, 505c, and NetCon control systems. Ideal for harsh environments, this module ensures real-time temperature data processing, enabling precise adjustments in machinery such as turbines, engines, and industrial equipment. Its compact design and robust construction make it a critical component for industries demanding accuracy and durability.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Input Type | Thermocouple (Type J, K, T, E, etc.) |

| Number of Channels | 8 channels |

| Operating Voltage | 24 VDC ±15% |

| Communication Interface | RS-485 |

| Control Algorithm | PID |

| Response Time | <1 ms |

| Temperature Range | -40°C to +70°C (Operating) |

| -55°C to +85°C (Storage) | |

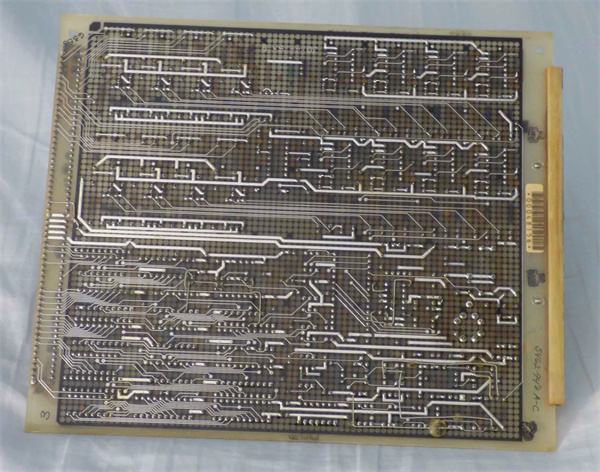

| Dimensions | 27.3 cm × 12.7 cm × 2.5 cm |

| Weight | 0.4 kg |

| Mounting | DIN rail |

WOODWARD 5462-948

3. Advantages and Features

- Multi-Channel Support: Simultaneously monitors 8 thermocouples, enhancing system efficiency.

- Wide Thermocouple Compatibility: Works with common T/C types, reducing replacement costs.

- Precision Measurement: Ensures accurate temperature readings for optimal process control.

- Built-in Diagnostics: Alerts operators to sensor faults or irregularities, minimizing downtime.

- Industrial-Grade Durability: Withstands extreme temperatures, vibrations, and EMI interference.

4. Application Areas and Use Cases

- Power Generation: Monitors turbine temperatures in steam and gas power plants.

- Manufacturing: Controls machinery heat in automotive and aerospace production lines.

- Chemical Processing: Maintains safe operating temperatures in reactors and distillation units.

- Oil & Gas: Manages engine and pipeline temperatures in drilling and refining operations.

Example Use Case: A chemical plant used the 5462-948 to monitor 8 reactors, preventing overheating and reducing energy consumption by 15% through precise PID control.

5. Competitor Comparison

The 5462-948 surpasses comparable modules with its higher channel density (8 vs. typical 4–6 channels) and broader thermocouple compatibility. Its integrated diagnostics and extended temperature range (-40°C to +70°C) also outperform competitors’ standard -20°C to +60°C limits.

The 5462-948 surpasses comparable modules with its higher channel density (8 vs. typical 4–6 channels) and broader thermocouple compatibility. Its integrated diagnostics and extended temperature range (-40°C to +70°C) also outperform competitors’ standard -20°C to +60°C limits.

WOODWARD 5462-948

6. Selection Recommendations

- Temperature Monitoring Needs: Choose this module for applications requiring 8-channel T/C input.

- System Compatibility: Ensure integration with Woodward’s 505e/c or NetCon platforms.

- Environmental Demands: Opt for the 5462-948 in high-vibration or wide-temperature environments.

- Cost Efficiency: Ideal for retrofitting older systems due to its plug-and-play design and minimal calibration requirements.

7. Precautions

- Sensor Installation: Use shielded cables and proper grounding to avoid signal interference.

- Thermocouple Type: Verify T/C compatibility with the module’s configuration settings.

- Temperature Limits: Do not exceed the specified operating temperature range.

- Maintenance: Regularly inspect connections and clean dust from ventilation slots for optimal performance.