Description

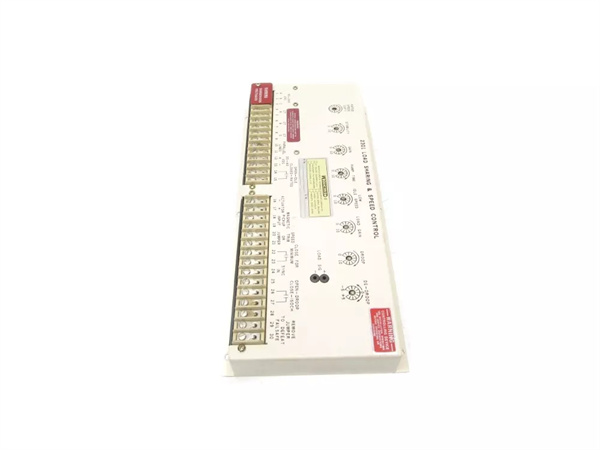

Woodward 8271-467 Speed Control Module

1. Product Description

The Woodward 8271-467 is a high-performance speed control module designed for industrial automation systems, delivering precise speed regulation and load management in challenging environments. With support for both PWM and analog control methods, it ensures seamless integration into diverse applications, including power generation, manufacturing, and chemical processing. The module’s advanced digital signal processing capabilities enable real-time adjustments, minimizing downtime and optimizing operational efficiency.

The Woodward 8271-467 is a high-performance speed control module designed for industrial automation systems, delivering precise speed regulation and load management in challenging environments. With support for both PWM and analog control methods, it ensures seamless integration into diverse applications, including power generation, manufacturing, and chemical processing. The module’s advanced digital signal processing capabilities enable real-time adjustments, minimizing downtime and optimizing operational efficiency.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Speed Control Module |

| Input Voltage | 24 V DC |

| Frequency Range | 0–60 Hz |

| Control Method | PWM or analog (0–20 mA/4–20 mA) |

| Response Time | <0.1 seconds |

| Overload Protection | 150% of rated load |

| Ambient Temperature | -40°C to +70°C |

| Dimensions | 150 mm × 100 mm × 30 mm |

| Weight | 0.5 kg |

| Communication | RS-485 Modbus RTU |

| Maximum Load Capacity | 1000 HP |

WOODWARD 8271-467

3. Advantages and Features

- Precision Control: 16-bit resolution ensures accurate speed adjustments for critical machinery.

- Wide Environmental Range: Operates reliably in extreme temperatures and harsh conditions.

- Fast Response: <0.1-second response time for dynamic load changes.

- Flexible Integration: Supports multiple signal types (0–20 mA/4–20 mA) and Modbus communication.

- Robust Design: Galvanic isolation and EMI shielding protect against electrical interference.

4. Application Areas and Use Cases

- Power Generation: Controls turbine speeds in gas and steam power plants.

- Manufacturing: Manages conveyor systems and motor-driven equipment in automotive and food processing.

- Chemical Processing: Regulates pumps and compressors in refineries and petrochemical facilities.

- HVAC Systems: Optimizes fan and blower speeds for energy efficiency.

Example Case: A European manufacturing plant reduced energy costs by 15% by integrating the 8271-467 to dynamically adjust motor speeds based on production demands.

5. Competitor Comparison

Compared to similar modules, the 8271-467 offers:

Compared to similar modules, the 8271-467 offers:

- Higher load capacity (1000 HP vs. typical 800 HP).

- Extended temperature range (-40°C to +70°C vs. -20°C to +60°C).

- Faster response time (0.1 sec vs. 0.2–0.3 sec in alternatives).

WOODWARD 8271-467

6. Selection Recommendations

- Load Requirements: Ensure compatibility with your machinery’s horsepower and torque needs.

- Environmental Conditions: Choose the module based on IP ratings (IP20 standard, optional IP65 for outdoor use).

- Signal Compatibility: Verify support for your control system’s analog or PWM inputs.

- Cost Efficiency: Balances upfront cost with long-term reliability (MTBF > 50,000 hours).

7. Precautions

- Installation: Use shielded cables for analog signals and follow proper grounding protocols.

- Calibration: Perform annual checks to maintain accuracy.

- Safety: Disconnect power before servicing. Ensure compliance with NEC Class 1 Div 2 standards in hazardous areas.