Description

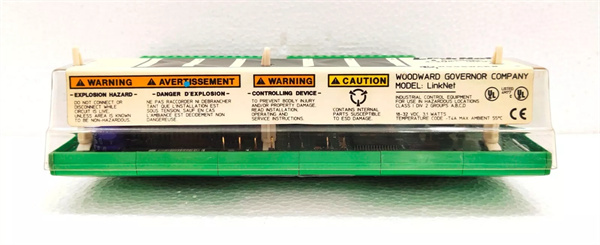

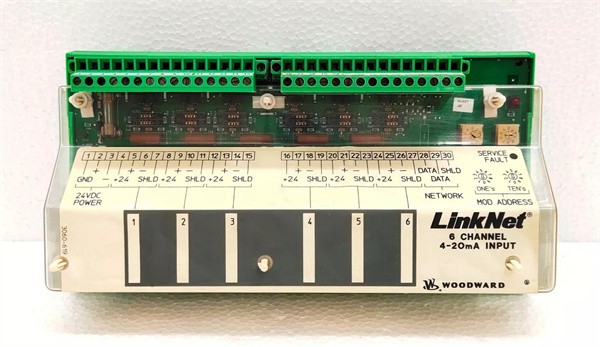

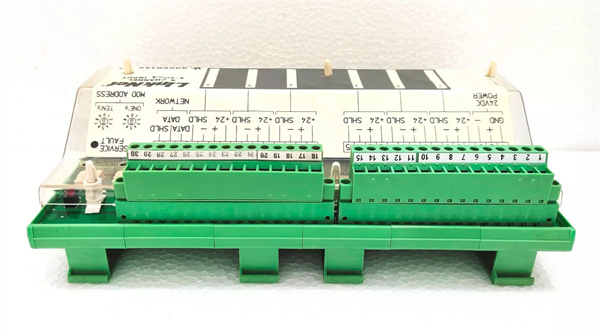

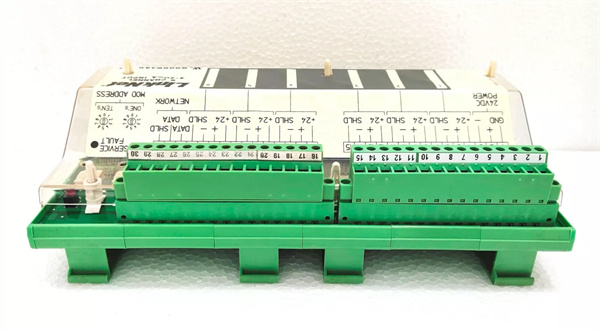

WOODWARD 9905-969 6-Channel Analog Input Module

1. Product Description

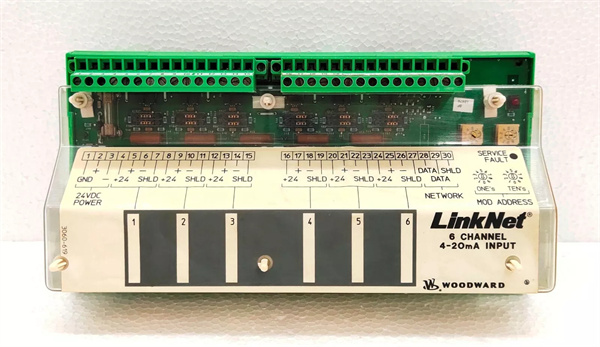

The WOODWARD 9905-969 is a high-performance analog input module designed for industrial automation systems, offering 6 channels for precise signal acquisition. Ideal for applications in power generation, oil & gas, and marine environments, this module supports 4–20 mA analog current inputs with 12-bit resolution and ±0.1% accuracy, ensuring reliable measurement of parameters like pressure, temperature, and flow. Built for durability, it operates across a wide temperature range (-40°C to +70°C) and features IP20 protection against dust and limited water exposure. Its Modbus RTU compatibility simplifies integration with control systems, enabling seamless data communication.

The WOODWARD 9905-969 is a high-performance analog input module designed for industrial automation systems, offering 6 channels for precise signal acquisition. Ideal for applications in power generation, oil & gas, and marine environments, this module supports 4–20 mA analog current inputs with 12-bit resolution and ±0.1% accuracy, ensuring reliable measurement of parameters like pressure, temperature, and flow. Built for durability, it operates across a wide temperature range (-40°C to +70°C) and features IP20 protection against dust and limited water exposure. Its Modbus RTU compatibility simplifies integration with control systems, enabling seamless data communication.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | 6-Channel Analog Input |

| Input Range | 4–20 mA DC |

| Supply Voltage | 24 VDC |

| Resolution | 12 bits |

| Accuracy | ±0.1% full scale |

| Communication | Modbus RTU |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +125°C |

| Dimensions | 22 x 11.5 x 7 cm |

| Weight | 0.54 kg |

WOODWARD 9905-969

3. Advantages and Features

- High Precision: 12-bit resolution and ±0.1% accuracy ensure reliable data acquisition.

- Wide Environmental Range: Operates in extreme temperatures and IP20-rated conditions.

- Flexible Connectivity: Modbus RTU support for easy integration with PLCs and control systems.

- Space-Saving Design: Compact form factor suitable for DIN rail mounting.

- Low Power Consumption: Efficient 24 VDC operation reduces energy costs.

4. Application Fields and Case Studies

- Power Generation: Monitors steam turbine performance in thermal power plants.

- Oil & Gas: Tracks pressure in drilling platforms and refineries.

- Manufacturing: Controls conveyor systems in automotive assembly lines.

- Case Study: A North American power plant reduced maintenance costs by 20% using the 9905-969 to monitor boiler pressure fluctuations.

5. Competitor Comparison

The 9905-969 stands out with its combination of 6-channel density, wide temperature tolerance, and Modbus RTU compatibility, surpassing many modules that require additional signal converters or offer limited environmental ratings.

WOODWARD 9905-969

6. Selection Recommendations

- Signal Requirements: Confirm 4–20 mA input compatibility with sensors.

- Environmental Conditions: Consider optional enclosures for outdoor or corrosive environments.

- System Integration: Ensure Modbus RTU support matches your control network.

- Redundancy: Pair with backup modules for critical operations.

7. Precautions

- ESD Protection: Use antistatic measures during installation.

- Voltage Stability: Maintain a clean 24 VDC power supply to avoid signal errors.

- Wiring: Shield cables to minimize electromagnetic interference.

- Firmware Updates: Regularly update firmware for optimal performance.