Description

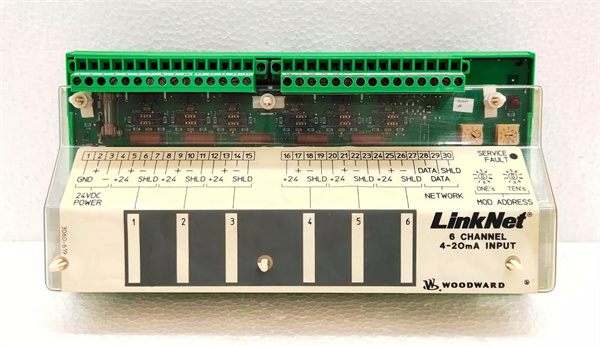

Woodward 9905-969 Multifunction Input Module

1. Product Description

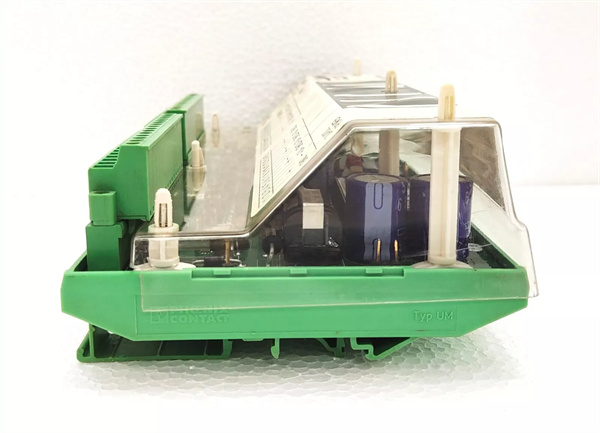

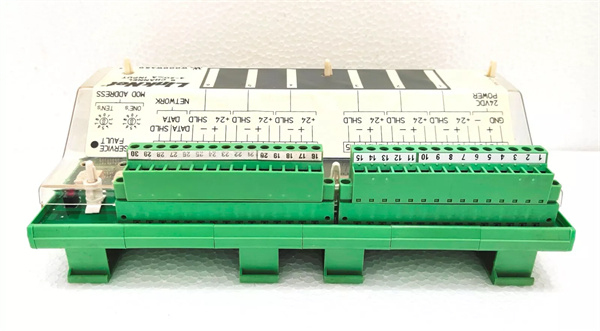

The Woodward 9905-969 is a high-performance multifunction input module engineered for industrial automation and control systems. It supports a wide range of analog and digital input signals, including thermocouples, RTDs, 4–20 mA current loops, and voltage signals, making it ideal for applications requiring precise monitoring and control in sectors like energy, manufacturing, and process industries. With advanced signal conditioning and noise filtering, this module ensures reliable data acquisition even in electrically noisy environments.

The Woodward 9905-969 is a high-performance multifunction input module engineered for industrial automation and control systems. It supports a wide range of analog and digital input signals, including thermocouples, RTDs, 4–20 mA current loops, and voltage signals, making it ideal for applications requiring precise monitoring and control in sectors like energy, manufacturing, and process industries. With advanced signal conditioning and noise filtering, this module ensures reliable data acquisition even in electrically noisy environments.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Multifunction Input Module |

| Input Voltage | 12–24 V DC |

| Input Signal Range | Thermocouples (Type K, J, T, E), RTDs (Pt100, Pt200), 0–10 V DC, 4–20 mA |

| Resolution | 16-bit (analog inputs) |

| Accuracy | ±0.1% of full scale |

| Communication Protocol | RS-485 (Modbus RTU) |

| Output Type | Digital (isolated transistor outputs) |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 120 mm × 50 mm × 20 mm |

| Weight | 0.3 kg |

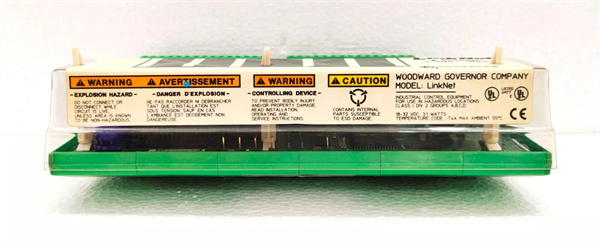

| Certifications | UL, CE, IEC 61131-2 |

WOODWARD 9905-969

3. Advantages and Features

- Versatile Signal Handling: Supports up to 8 channels for mixed input types, reducing system complexity.

- High Precision: 16-bit resolution ensures accurate measurements for critical control loops.

- Enhanced Noise Immunity: Galvanic isolation and EMI/RFI shielding protect against signal interference.

- Wide Environmental Range: Operates reliably in extreme temperatures and harsh conditions.

- Low Power Consumption: ≤3 W during operation, contributing to energy efficiency.

4. Application Areas and Use Cases

- Energy Generation: Monitors temperature and current in gas turbines, generators, and renewable energy systems.

- Manufacturing: Controls processes in automotive assembly lines, semiconductor fabrication, and food processing.

- Chemical Processing: Manages pressure and temperature in reactors and distillation columns.

- HVAC Systems: Optimizes climate control in smart buildings and data centers.

Example Case: A North American power plant integrated the 9905-969 to monitor turbine temperatures, reducing maintenance costs by 20% through predictive analytics enabled by its high-precision data.

5. Competitor Comparison

Compared to similar modules, the 9905-969 offers:

Compared to similar modules, the 9905-969 offers:

- Higher input resolution (16-bit vs. 12–14-bit in many alternatives).

- Simultaneous support for up to 8 channels of mixed signal types.

- Extended temperature range (-40°C to +85°C vs. typical -20°C to +70°C).

WOODWARD 9905-969

6. Selection Recommendations

- Input Requirements: Ensure compatibility with your sensor types (e.g., thermocouple/RTD) and signal ranges.

- Environmental Needs: Choose the module based on IP ratings (IP20 standard, optional IP65 for outdoor use).

- System Integration: Verify RS-485/Modbus RTU compatibility with your PLC/DCS system.

- Cost Efficiency: Balances upfront cost with long-term reliability (MTBF > 60,000 hours).

7. Precautions

- Installation: Use shielded cables for analog signals and observe proper grounding to minimize noise.

- Calibration: Perform factory-recommended recalibration every 2 years.

- Safety: Disconnect power before replacing the module. Ensure compliance with NEC Class 1 Div 2 standards in hazardous environments.