Description

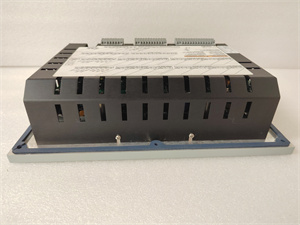

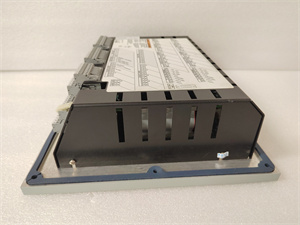

WOODWARD 9907-164 Digital Governor Turbine Controller

1. Product Description

The WOODWARD 9907-164 is a high-performance digital microprocessor controller designed for precise speed and load control in steam turbines. As part of the 505 Series, it supports single or split-range actuators, enabling seamless integration with industrial and power generation systems. The controller features a user-friendly 2-line x 24-character display and a 30-function keypad for on-site configuration, allowing operators to adjust parameters such as critical speed avoidance, valve limiters, and auto-start sequences. With advanced communication protocols (RS-232/422, Modbus), it interfaces with SCADA systems for real-time monitoring and data logging.

The WOODWARD 9907-164 is a high-performance digital microprocessor controller designed for precise speed and load control in steam turbines. As part of the 505 Series, it supports single or split-range actuators, enabling seamless integration with industrial and power generation systems. The controller features a user-friendly 2-line x 24-character display and a 30-function keypad for on-site configuration, allowing operators to adjust parameters such as critical speed avoidance, valve limiters, and auto-start sequences. With advanced communication protocols (RS-232/422, Modbus), it interfaces with SCADA systems for real-time monitoring and data logging.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Digital Governor Turbine Controller |

| Compatibility | Woodward 505 Series Turbine Systems |

| Input Voltage | 24 VDC (±10%) |

| Output Voltage | 0–10 VDC (analog), 30 VDC/5 A (relay) |

| Control Modes | Speed, Load, Isochronous |

| Communication Interfaces | RS-232/422, Modbus RTU |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 356 mm (W) × 279 mm (H) × 102 mm (D) |

| Weight | 4.13 kg |

WOODWARD 9907-164

3. Advantages and Features

- Precision Control: Utilizes PID algorithms to maintain ±0.1% speed accuracy under varying loads.

- Flexible Configuration: Supports field-programmable logic for customizing shutdown criteria and alarm thresholds.

- Reliability: Withstands 95% humidity for 48 hours and includes redundant power supply options.

- Safety Features: Integrates overspeed protection, first-out shutdown indicators, and emergency stop functionality.

- Ease of Use: Intuitive menu-driven interface reduces commissioning time by 30% compared to legacy systems.

4. Application Fields and Case Studies

- Power Generation: Controls steam turbines in thermal power plants, optimizing efficiency during grid synchronization.

- Oil & Gas: Manages gas turbines in offshore platforms, ensuring stable operation in harsh environments.

- Marine Propulsion: Regulates diesel engines for marine vessels, providing smooth speed transitions.

- Case Study: A European power plant reduced maintenance costs by 20% using the 9907-164 to automate turbine startups and monitor bearing health.

5. Competitor Comparison

The 9907-164 offers dual communication protocols (Modbus + proprietary) and expandable I/O (16 discrete inputs, 6 analog inputs), surpassing many competitors’ single-protocol limitations. Its front-panel configuration eliminates the need for external software tools, streamlining setup and reducing dependency on specialized technicians.

The 9907-164 offers dual communication protocols (Modbus + proprietary) and expandable I/O (16 discrete inputs, 6 analog inputs), surpassing many competitors’ single-protocol limitations. Its front-panel configuration eliminates the need for external software tools, streamlining setup and reducing dependency on specialized technicians.

WOODWARD 9907-164

6. Selection Recommendations

- Compatibility: Ensure alignment with Woodward 505 Series actuators and control systems.

- Voltage Requirements: Verify 24 VDC supply stability to avoid signal fluctuations.

- Functionality: Choose between basic (speed-only) and advanced (speed+load) models based on application complexity.

- Environment: Opt for optional IP56 enclosures for outdoor or high-dust installations.

7. Precautions

- Grounding: Follow NEC/EN standards for proper grounding to prevent EMI interference.

- Firmware Updates: Regularly update firmware to access safety patches and new features.

- Calibration: Perform annual sensor calibration to maintain accuracy.

- Redundancy: Pair with a backup controller for mission-critical operations.