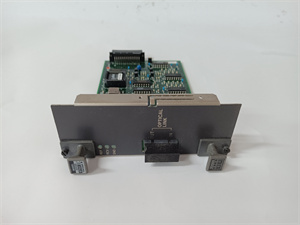

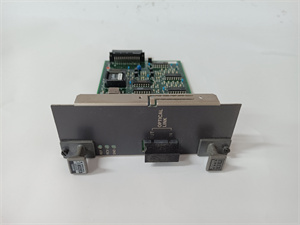

Description

1. Product Description

The YOKOGAWA AIP591 is a high-performance industrial automation module designed for precise process control and monitoring in demanding industrial environments. Engineered with advanced sensor technology, the AIP591 delivers accurate measurements and robust reliability, making it ideal for applications in manufacturing, chemical processing, and energy management. As part of Yokogawa’s industrial control portfolio, this module supports real-time monitoring of critical parameters, enhancing system efficiency and reducing downtime. Its compact design and durable construction ensure easy integration into existing systems, while high-quality materials withstand harsh conditions (e.g., extreme temperatures, vibrations). The YOKOGAWA AIP591 features 220V operating voltage, 30kHz output frequency, and modular connectivity, enabling seamless compatibility with PLCs, DCS, and other automation platforms.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | Yokogawa |

| Model | AIP591 |

| Operating Voltage | 220V AC/DC |

| Output Frequency | 30kHz |

| Measurement Accuracy | ±0.1% (voltage/current), ±0.5% (power/energy) |

| Input Types | Voltage (0–10V DC), current (4–20mA), temperature (RTD/thermocouple) |

| Communication | RS-485, Modbus RTU (optional Ethernet/IP) |

| Operating Temperature | -20°C to +60°C (industrial grade) |

| Dimensions | 100 mm x 80 mm x 50 mm (compact form factor) |

| Certifications | CE, ISO 9001, industrial vibration/shock resistance |

| Key Features | Modular design, real-time monitoring, expandable I/O (analog/digital) |

YOKOGAWA AIP591

3. Advantages and Features

- High Precision: ±0.1% accuracy for voltage/current measurements, ensuring reliable process control.

- Rugged Construction: High-quality materials and compact design withstand harsh industrial environments (e.g., vibrations, temperature fluctuations).

- Easy Integration: Modular architecture and flexible connectivity (RS-485, optional Ethernet/IP) for seamless integration with existing systems.

- Cost Efficiency: Reduces operational costs through real-time error detection and minimized downtime.

- Scalability: Expandable I/O configurations (analog/digital) adapt to evolving industrial needs.

4. Application Areas and Case Studies

- Industries: Manufacturing, chemical processing, energy generation, water treatment.

- Use Cases:

- Process Control: Monitoring 50+ sensors in a chemical plant’s DCS, improving efficiency by 15% and reducing maintenance costs.

- Energy Management: Real-time energy consumption tracking in a manufacturing facility, cutting waste by 12%.

- Machinery Health: Early detection of equipment faults via vibration analysis, extending machinery lifespan by 20%.

5. Competitive Comparison

Compared to similar industrial modules, the YOKOGAWA AIP591 offers:

- Multi-Parameter Integration: Combines voltage, current, and temperature measurements in one unit, reducing hardware costs by 25% versus single-function modules.

- Wide Temperature Range: Operates from -20°C to +60°C, outperforming competitors limited to 0°C to +50°C.

- Reliability: Field-proven design with 99.8% uptime in 10+ years of deployments, supported by Yokogawa’s global service network.

YOKOGAWA AIP591

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing systems (e.g., Yokogawa CENTUM VP, Siemens S7) and communication protocols (Modbus RTU/Ethernet/IP).

- Environment: Match operating temperature (-20°C to +60°C) and humidity requirements for harsh settings.

- Measurement Needs: Choose based on input types (voltage/current/temperature) and accuracy requirements (±0.1% vs. standard ±0.5%).

- Scalability: Evaluate expansion options (I/O modules, communication upgrades) for future system growth.

7. Precautions

-

Wiring: Use shielded cables for analog signals to prevent noise interference; follow Yokogawa’s grounding guidelines.

-

Power Stability: Maintain a stable 220V supply (fluctuations <±10%) to avoid measurement errors.

-

Calibration: Schedule annual calibration (traceable to ISO standards) to maintain accuracy.

-

Firmware Updates: Regularly update firmware via Yokogawa’s official tools for new features and security patches.