Description

1. Product Description

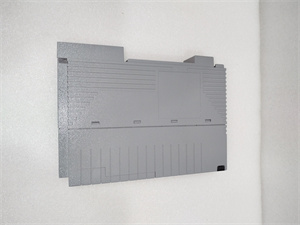

The YOKOGAWA CP451-10 is a 16-channel digital input/output (I/O) module designed for Yokogawa’s Centum CS 3000 and Centum VP distributed control systems (DCS). Engineered for industrial automation, the CP451-10 supports multiple signal types (on/off, high/low) and integrates advanced diagnostic functions for channel and module fault detection. With a compact design (89 mm × 64 mm × 25 mm) and rail-mounted installation, it simplifies integration into process control systems across industries such as manufacturing, chemical, and energy. The module operates on 24V DC power, ensuring stable performance in harsh environments (0°C to 60°C operating temperature, 5–95% non-condensing humidity).

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Type | Digital input/output module |

| Channels | 16 (configurable for input/output) |

| Signal Types | On/off, high/low (24V DC compatible) |

| Diagnostic Functions | Channel fault, module fault, status indicators (LEDs for module/channel status) |

| Power Supply | 24V DC ±10% |

| Power Consumption | 10W maximum |

| Operating Temperature | 0°C to 60°C (storage: -40°C to 85°C) |

| Humidity | 5–95% RH (non-condensing) |

| Installation | DIN rail (IP20 protection) |

| Weight | 0.25 kg |

| Compatibility | Centum CS 3000, Centum VP DCS systems |

Yokogawa CP451-10

3. Advantages and Features

- Dual-Function I/O: 16 configurable channels for both digital input and output, reducing module redundancy.

- Advanced Diagnostics: Real-time channel and module fault detection with LED indicators for quick troubleshooting.

- Rugged Design: Withstands extreme temperatures (-40°C to 85°C storage) and industrial vibrations (IEC 60068-2-6 standards).

- Space Efficiency: Compact size (89 mm × 64 mm) ideal for dense control panels.

- Easy Integration: Plug-and-play compatibility with Yokogawa DCS systems, minimizing setup time.

4. Application Areas and Cases

- Industry Applications: Industrial control, machinery manufacturing, metallurgy, chemical processing, textiles, food and beverage.

- Use Cases:

- Production Line Control: Monitors conveyor belt operations (e.g., motor on/off signals) in automotive manufacturing, with fault diagnostics triggering immediate alerts.

- Chemical Processing: Controls valve actuators in reactor systems, ensuring safe on/off operations with 16-channel redundancy.

5. Competitor Comparison

Compared to similar digital I/O modules:

- Higher Channel Density: 16 channels (vs. typical 8–12 channels in 竞品), reducing panel space and cost.

- Enhanced Diagnostics: Built-in channel-level fault detection (uncommon in basic I/O modules).

- Wide Temperature Range: Operates at 0°C to 60°C (extends usability in unregulated industrial environments).

Yokogawa CP451-10

6. Selection Recommendations

- System Compatibility: Ensure compatibility with Centum CS 3000/VP DCS (verify firmware version ≥1.x).

- Environment: Match temperature/humidity requirements (e.g., avoid condensation for long-term reliability).

- Channel Needs: Choose the CP451-10 for 16-channel systems; consider CP451-50 (replacement model) for advanced features (e.g., explosion protection).

- Budget: Balance channel density (16 channels) against project scale (cost-effective for medium-to-large systems).

7. Precautions

- Installation: Secure rail mounting (IP20 protection; avoid direct liquid exposure).

- Wiring: Use shielded cables for signal lines to prevent EMI. Maintain 24V DC power stability (±10% tolerance).

- Maintenance: Regularly inspect LED indicators for fault status. Replace modules every 5–7 years (based on Yokogawa maintenance guidelines).

- Safety: Disconnect power before servicing. Follow IEC 61508 standards for safety-critical applications.