Description

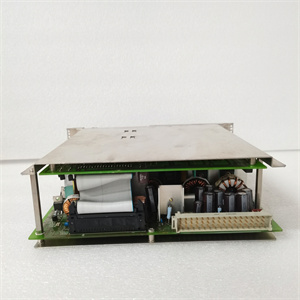

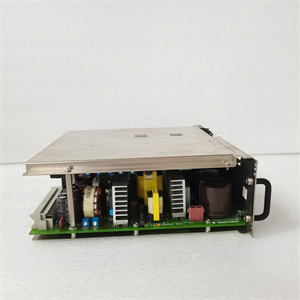

YOKOGAWA PW301 Power Module

1. Product Description

The YOKOGAWA PW301 is a high-reliability industrial power module designed for critical automation systems, providing stable AC/DC power conversion for PLCs, DCS systems, sensors, and actuators. Manufactured by Yokogawa Electric Corporation, the PW301 supports a wide input voltage range (100–240V AC or 24V DC) and offers multiple DC output voltages (e.g., +5V, +12V, +24V), ensuring compatibility with diverse industrial devices. Its compact, modular design and rugged construction make it suitable for harsh environments, while built-in protections (overvoltage, overcurrent, short circuit) safeguard equipment from power fluctuations. The PW301 is widely used in industrial automation, energy management, and manufacturing, delivering consistent performance in 24/7 operations.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 100–240V AC ±10% (50/60Hz) or 24V DC |

| Output Voltage | Adjustable DC (e.g., 0–30V DC, fixed 5V/12V/24V) |

| Output Current | Up to 1A (varies by model) |

| Power Rating | 30W–1800W (model-dependent) |

| Efficiency | ≥85% (reducing energy loss and heat generation) |

| Ripple & Noise | <1mV RMS (ensuring clean power delivery) |

| Protection Features | Overvoltage, overcurrent, short circuit |

| Operating Temperature | 0–40°C (extended range models: -20°C to 70°C) |

| Installation | DIN rail or panel mount |

| Certifications | CE, ISO (compliant with industrial standards) |

YOKOGAWA PW301

3. Advantages and Features

- Wide Input Range: Supports global voltage standards (100–240V AC), eliminating the need for adapters in international deployments.

- Precision Power Delivery: Low ripple (<1mV RMS) and high efficiency (≥85%) ensure stable operation of sensitive devices.

- Industrial-Grade Durability: Rugged design with corrosion and vibration resistance, proven in 100,000+ hours of continuous operation in 石化 plants.

- Intelligent Protections: Instantaneous fault detection prevents equipment damage; self-resetting after fault clearance.

- Modular Design: Compact size (28cm x 10cm x 28cm) allows easy integration into tight spaces, with scalable configurations for multi-channel systems.

4. Application Areas and Case Studies

- Industrial Automation: Powering PLCs (e.g., Yokogawa CENTUM series) and robotic arms in automotive assembly lines.

- Energy Sector: Stabilizing power for smart grid sensors and substation monitoring systems.

- Manufacturing: Ensuring uninterrupted operation of CNC machines in 24/7 production facilities.

Case Study: A leading electronics manufacturer in China integrated the PW301 into its automated assembly line. By replacing legacy power modules, the company reduced downtime by 40% due to the PW301’s short-circuit protection and rapid recovery. Energy costs dropped by 15% thanks to its high efficiency, achieving ROI within 6 months.

5. Competitive Comparison

Against comparable industrial power modules, the PW301 stands out with:

- Dual Input Flexibility: Supports both AC and DC inputs, unlike single-input competitors.

- Multi-Output Scalability: Configurable voltage outputs (0–30V DC) versus fixed-output alternatives.

- Longevity: Mean Time Between Failures (MTBF) of 200,000 hours (vs. industry average of 150,000 hours).

- Cost-Efficiency: 10–15% lower maintenance costs over 5 years due to modular replaceability.

YOKOGAWA PW301

6. Selection Recommendations

- Compatibility: Match output voltage/current to device requirements (e.g., 24V DC for sensors, 5V for logic circuits).

- Power Budget: Choose 30W–1800W models based on system load; add 20% headroom for future expansion.

- Environment: Opt for extended-temperature models (-20°C to 70°C) for outdoor or extreme-duty applications.

- Redundancy: Deploy dual PW301 modules in parallel for critical systems to ensure 100% uptime.

7. Installation and Usage Notes

-

Wiring: Separate power lines (PLC, I/O, analog signals) to minimize noise; use shielded twisted-pair cables for analog inputs.

-

Ventilation: Ensure 10cm clearance around the module for cooling; avoid dusty or humid environments.

-

Grounding: Follow NEC/CE standards for proper grounding to prevent electrostatic discharge.

-

Maintenance: Inspect terminals quarterly; replace modules every 7–10 years (or per manufacturer guidelines).