Description

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Digital Input Module (TMR-based) |

| Input Channels | 32 isolated channels |

| Input Voltage | 24V DC (11–30V DC tolerant) |

| Contact Type | Dry contacts or solid-state switches |

| Isolation | 500V RMS channel-to-chassis |

| Debounce Time | Programmable (1–500 ms) |

| Redundancy Support | TMR architecture (triple redundancy) |

| Operating Temperature | -40°C to +70°C |

| Certifications | IEC 61508 (SIL 3), ATEX, CSA |

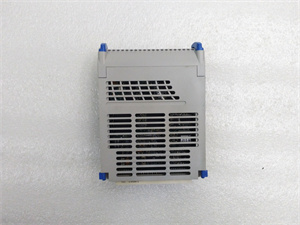

| Dimensions | 177 mm (H) × 48 mm (W) × 203 mm (D) |

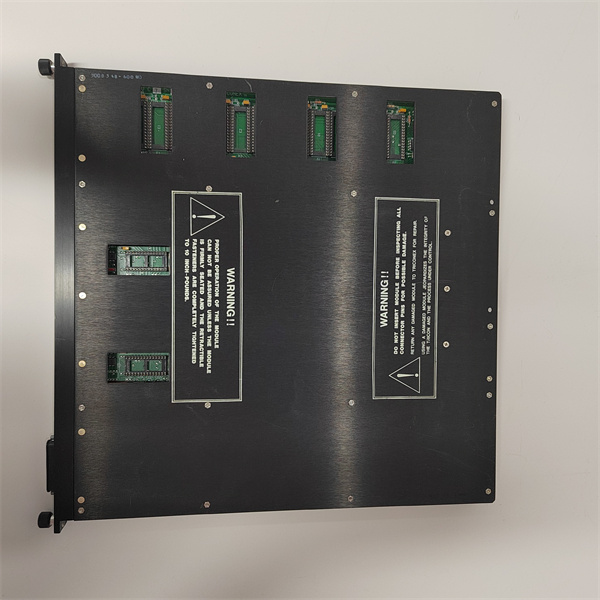

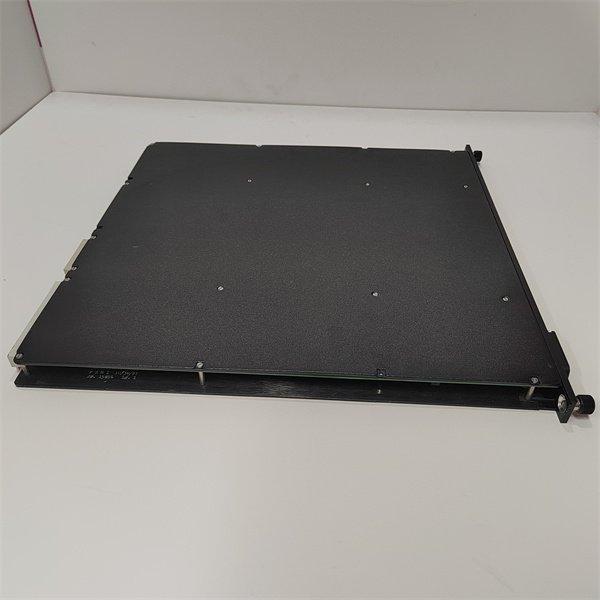

TRICONEX 3006

3. Advantages and Features

4. Application Areas and Cases

- Application Areas:

- Oil & gas production (wellhead control, pipeline monitoring)

- Chemical plants (safety interlocks, reactor status monitoring)

- Power generation (turbine safety systems, switchgear control)

- Application Case: A major pharmaceutical plant integrated the 3006 into its sterile production line’s SIS to monitor 24 limit switches and 8 emergency stop buttons. The module’s TMR architecture and noise immunity ensured reliable signal processing during high-speed production, preventing false alarms and maintaining compliance with FDA regulations. The plant reported a 30% reduction in maintenance time due to the module’s user-friendly diagnostics.

5. Competitor Comparison

Compared to non-TMR digital input modules, the TRICONEX 3006 offers superior fault tolerance and SIL 3 compliance, eliminating the need for external redundant components. Its wide operating temperature range and robust isolation exceed standard industrial modules, making it suitable for extreme environments. Unlike generic alternatives, the 3006 integrates seamlessly with TRICONEX’s Tricon controllers, ensuring deterministic performance and simplified system design.

TRICONEX 3006

6. Selection Advice

- System Compatibility: Ensure the module is compatible with your TRICONEX controller and backplane to leverage full TMR capabilities.

- Input Requirements: Verify voltage levels, contact types, and channel count match your field devices (e.g., proximity switches, pushbuttons).

- Safety Needs: Prioritize the 3006 for applications requiring fault tolerance and SIL 3 compliance, such as SIS or safety-critical control loops.

- Environmental Factors: Assess temperature, humidity, and EMI levels to ensure the module’s rugged design is suitable for your site.

7. Precautions

- Wiring Practices: Use shielded cabling and follow TRICONEX’s grounding guidelines to minimize interference. Avoid overloading terminals beyond the rated current.

- Configuration: Use TriStation software to program debounce settings and enable redundancy features. Validate configurations through thorough testing.

- Maintenance: Regularly review diagnostic reports for channel health. Replace faulty modules promptly to maintain system integrity, and schedule periodic firmware updates to address security and performance enhancements.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.