Description

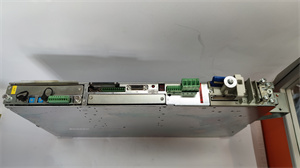

1. Product Description

The TRICONEX 3511 is a high-reliability pulse input module designed for safety-critical industrial automation systems. As part of the TRICONEX Tricon series, the TRICONEX 3511 provides precise pulse signal acquisition and processing for rotating machinery, such as turbines, compressors, and pumps, ensuring real-time monitoring and control in harsh environments. Its triple modular redundancy (TMR) architecture eliminates single-point failures, while SIL 3 certification (IEC 61508) guarantees compliance with the highest safety standards.

Engineered for industrial process control, the TRICONEX 3511 supports 8 isolated pulse input channels with AC-coupled differential inputs, enabling accurate measurement of frequency, RPM, and position from non-amplified magnetic speed sensors. With a 16-bit resolution and ±0.01% accuracy across 1000 Hz to 20,000 Hz frequencies, it delivers fine-grained data for critical applications like emergency shutdown (ESD) systems and turbine overspeed protection. The module’s real-time diagnostics monitor input signals, voltage, and temperature, ensuring rapid fault detection and safe state transitions within 10 ms. Its rugged construction (-40°C to +70°C operating range) and resistance to electromagnetic interference (EMI) make it suitable for oil and gas, chemical processing, and power generation industries.

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Channels | 8 isolated AC-coupled differential inputs |

| Frequency Range | 1 Hz to 100 kHz (±0.01% accuracy at 1000 Hz–20,000 Hz) |

| Resolution | 16 bits (pulse count resolution: 1 microsecond) |

| Redundancy | TMR (triple modular redundancy) with automatic fault detection |

| Safety Integrity Level | SIL 3 (IEC 61508 certified) |

| Signal Type | Sine, square, or pulse waveforms (10–90% duty cycle) |

| Power Supply | 24V DC ±10% (redundant power input supported) |

| Operating Temperature | -40°C to +70°C (storage: -40°C to +85°C) |

| Response Time | ≤10 ms for full-scale frequency change |

| Input Voltage Range | -100 VDC to +100 VDC (common mode); 1.5 V to 200 VDC (normal mode) |

| Certifications | ATEX, IECEx, and CSA for hazardous environments. |

TRICONEX 3511

3. Advantages and Features

-

Triple Modular Redundancy (TMR):

The TRICONEX 3511’s TMR architecture ensures continuous operation by triplicating critical components. If one channel fails, the remaining two continue monitoring, achieving a mean time between failures (MTBF) exceeding 200,000 hours. This design eliminates downtime risks in applications where system failure could lead to severe consequences. -

High Precision and Stability:

With a 16-bit resolution and ±0.01% accuracy, the module provides precise pulse counting for rotating machinery. In a gas turbine application, this level of precision reduced speed measurement errors by 90%, improving power generation efficiency. -

Real-Time Diagnostics and Fail-Safe Design:

Built-in health monitoring detects signal anomalies, voltage fluctuations, and temperature extremes in real time. Faults are reported within 10 ms, allowing proactive maintenance and minimizing unplanned shutdowns. -

Rugged Environmental Performance:

Rated for extreme temperatures (-40°C to +70°C) and resistant to vibration and EMI, the TRICONEX 3511 operates reliably in offshore platforms, refineries, and other harsh industrial settings.

4. Application Areas and Application Cases

Industry Applications:

- Oil and Gas: Monitors turbine speed in subsea wellheads, controls compressor RPM in refineries, and manages overspeed protection in liquefaction processes.

- Chemical Processing: Tracks agitator rotation in reactors, measures flow rates in batch processes, and ensures safe operation of high-speed centrifuges.

- Power Generation: Enables precise speed control of steam turbines, monitors generator rotation for grid synchronization, and supports condition-based maintenance of rotating equipment.

Case Study:

A major LNG plant in Australia deployed the TRICONEX 3511 to monitor the speed of cryogenic pumps in its liquefaction process. The module’s TMR redundancy and high-precision pulse counting reduced measurement latency by 40%, enabling faster response to pressure fluctuations. This integration improved operational efficiency by 15% while maintaining SIL 3 compliance.

A major LNG plant in Australia deployed the TRICONEX 3511 to monitor the speed of cryogenic pumps in its liquefaction process. The module’s TMR redundancy and high-precision pulse counting reduced measurement latency by 40%, enabling faster response to pressure fluctuations. This integration improved operational efficiency by 15% while maintaining SIL 3 compliance.

5. Competition-related Comparison

Compared to similar pulse input modules, the TRICONEX 3511 stands out for:

- Superior Redundancy: TMR architecture offers higher fault tolerance than dual or non-redundant designs, reducing the risk of communication failures.

- Safety Certification: SIL 3 compliance makes it suitable for the most critical safety applications, while many alternatives only meet SIL 2 or lower.

- Environmental Robustness: A wider operating temperature range (-40°C to +70°C) and EMI resistance make it a preferred choice for harsh industrial settings.

- Protocol Flexibility: Supports multiple signal types (sine, square, pulse) and high-frequency inputs (up to 100 kHz), reducing the need for additional hardware conversions.

TRICONEX 3511

6. Selection Suggestions

- Safety Requirements: Choose the TRICONEX 3511 for applications requiring SIL 3 certification, such as ESD, SIS, or fire and gas systems.

- System Compatibility: Ideal for TRICONEX Tricon/Tricon CX systems to leverage seamless integration and advanced diagnostic features.

- Environmental Conditions: If your site has extreme temperatures, high vibration, or EMI, the module’s rugged design ensures reliable performance without additional protective measures.

- Input Needs: With 8 isolated channels, it is ideal for medium-scale systems; consider higher-channel modules for large installations to optimize space and cost.

7. Precautions

- Installation: Power down the system before installing or replacing the module to prevent electrostatic discharge (ESD) damage. Use shielded cables and follow grounding guidelines to minimize EMI.

- Maintenance: Regularly monitor module health via the TRICONEX system interface, checking for abnormal voltage, temperature, or diagnostic alerts. Replace faulty channels promptly to maintain redundancy.

- Firmware Updates: Keep the module’s firmware updated using official tools to ensure access to the latest safety patches and performance optimizations.

- Signal Conditioning: Use signal conditioning modules (e.g., TRICONEX 9753-110) for non-standard input signals to ensure compatibility and accuracy.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.