Description

1. Product Description

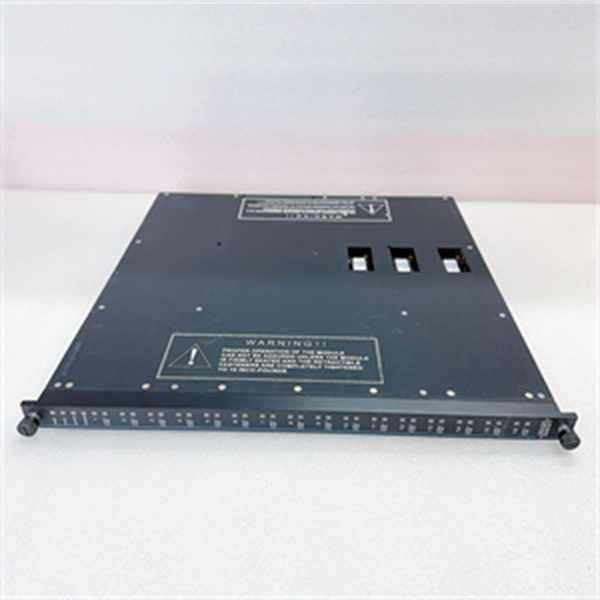

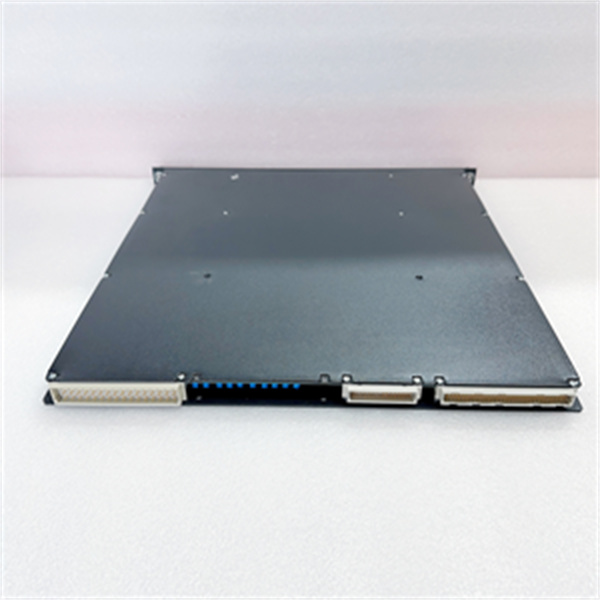

The TRICONEX 3623T is a high-reliability Temperature Digital Input Module designed for safety-critical industrial automation systems. As a key component of TRICONEX’s Triple Modular Redundancy (TMR) architecture, the TRICONEX 3623T ensures precise and dependable acquisition of temperature signals from field devices in environments where system failure is not an option.

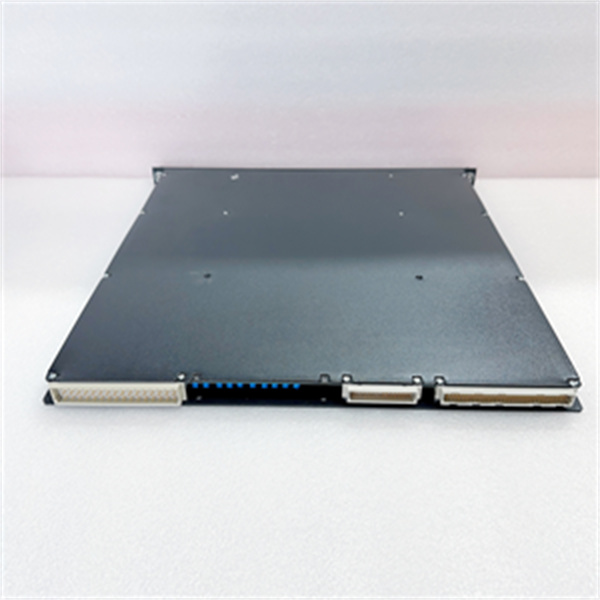

The core function of the TRICONEX 3623T is to monitor and convert temperature signals from sensors such as thermocouples (TC) or resistance temperature detectors (RTD) into digital data for processing by control systems. It supports 16 isolated temperature input channels, each capable of accepting a wide range of temperature sensor signals with built-in signal conditioning and noise filtering to ensure accuracy. The module employs a 2-out-of-3 voting logic across three independent channels, ensuring that even a single-channel failure does not compromise data integrity. This design is critical for maintaining operational safety in applications requiring precise temperature monitoring, such as reactor control, turbine protection, and safety instrumented systems (SIS).

Key advantages of the TRICONEX 3623T include its SIL-3 certification (IEC 61508), which attests to its suitability for the highest safety integrity level requirements, and its rugged design that withstands harsh industrial conditions. The module also features hot-swappable functionality, allowing for maintenance or replacement without powering down the system, and advanced diagnostics that monitor channel health and sensor connectivity in real time.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Temperature Digital Input Module for safety-critical systems |

| Input Channels | 16 isolated channels (supports TC: J, K, T, E, R, S, B; RTD: 2-wire, 3-wire, 4-wire) |

| Redundancy | Triple Modular Redundancy (TMR) with 2-out-of-3 voting logic |

| Temperature Range | Thermocouple: -200°C to +1800°C; RTD: -200°C to +650°C |

| Resolution | 16-bit for RTD; 14-bit for thermocouple |

| Accuracy | ±0.1% of full scale (RTD); ±1°C (thermocouple, typical) |

| Isolation | 1,500 VDC between channels and ground |

| Operating Temperature | -40°C to +70°C (storage: -40°C to +85°C) |

| Humidity | 5%–95% non-condensing |

| SIL Certification | SIL-3 (IEC 61508), suitable for safety-critical applications |

| Compatibility | TRICONEX Tricon CX, EX, and legacy systems; integrates with SCADA and DCS |

| Power Consumption | < 20 W (maximum under full load) |

TRICONEX 3623T

3. Advantages and Characteristics

- Triple Modular Redundancy (TMR): The TRICONEX 3623T’s TMR architecture with 2-out-of-3 voting logic ensures that the module can continue operating even if one channel fails, achieving a mean time between failures (MTBF) exceeding 500,000 hours. This reduces the risk of erroneous temperature signal acquisition by up to 90% compared to non-redundant modules.

- SIL-3 Safety Compliance: Certified to the highest safety integrity level, the module is ideal for applications where precise temperature monitoring is critical, such as preventing overheating in chemical reactors or ensuring turbine safety in power plants.

- Multi-Sensor Support: Supports both thermocouples and RTDs without hardware changes, offering flexibility for diverse temperature measurement needs. In a refinery project, this feature eliminated the need for separate modules, reducing inventory costs by 30%.

- Hot-Swap Capability: Faulty modules can be replaced while the system is operational, minimizing downtime during maintenance. Technicians can replace a module in under 20 minutes without disrupting process control, ensuring continuous monitoring in critical applications.

- Rugged Environmental Performance: Designed to operate in extreme temperatures and high-vibration environments, the module has been proven reliable in offshore platforms and heavy industrial settings, withstanding conditions such as -40°C cold snaps and 5g vibration levels.

4. Application Areas and Application Cases

-

Industry Applications:

- Oil & Gas: Monitors temperature in wellheads, pipelines, and LNG storage tanks to prevent freezing or overheating.

- Chemical Processing: Acquires temperature signals from reactor vessels, distillation columns, and heat exchangers for safety interlock systems.

- Power Generation: Supports temperature monitoring in steam turbines, generators, and boiler systems to ensure optimal performance and safety.

-

Case Study:

A large petrochemical plant in the Middle East integrated the TRICONEX 3623T into its SIS to monitor 100+ temperature points in a catalytic cracking unit. The module’s TMR technology and real-time diagnostics detected a faulty RTD channel during normal operation, allowing the system to automatically use data from the redundant channels while maintaining full signal integrity. This prevented a potential process upset caused by inaccurate temperature readings, safeguarding against costly production interruptions.

5. Competitive Comparison

Compared to similar temperature input modules, the TRICONEX 3623T stands out for its combination of SIL-3 certification, TMR redundancy, and multi-sensor compatibility. While some alternatives support basic temperature measurement, few match its ability to handle safety-critical applications with both thermocouple and RTD inputs in a compact form factor. Its advanced diagnostics and hot-swappable design also reduce maintenance complexity, making it a preferred choice for industries where measurement accuracy and system availability are non-negotiable.

TRICONEX 3623T

6. Selection Recommendations

- System Compatibility: Ensure the module is compatible with your TRICONEX control system (e.g., Tricon CX, EX) and backplane configuration. Verify software versions to ensure proper sensor type configuration and voting logic setup.

- Sensor Requirements: Confirm that the module supports your specific sensor type (thermocouple or RTD) and wiring configuration (2-wire, 3-wire, 4-wire) to avoid signal inaccuracies.

- Environmental Needs: If installing in harsh environments (e.g., high-temperature refineries or cold offshore sites), ensure the module’s operating temperature range aligns with your site conditions.

- Redundancy Strategy: For critical temperature monitoring loops, pair the TRICONEX 3623T with redundant power supplies and communication networks to maximize system availability and fault tolerance.

7. Precautions

- Installation: Power down the system and use anti-static wrist straps during installation to prevent electrostatic discharge (ESD) damage. Use shielded cables for sensor connections to minimize electromagnetic interference (EMI) and ensure proper grounding.

- Configuration: Use TRICONEX’s approved software tools (e.g., Tristation 1131) to configure sensor types, calibration parameters, and voting logic, ensuring alignment with your safety loop requirements.

- Maintenance: Regularly review the module’s diagnostic status via the control system interface to monitor channel health and sensor connectivity. Schedule firmware updates to incorporate the latest safety patches and performance optimizations.

- Troubleshooting: In the event of a channel fault or sensor discrepancy, replace the module or sensor during a planned maintenance window or while the system is in hot-standby mode to avoid disrupting operations.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.