Description

1. Product Description

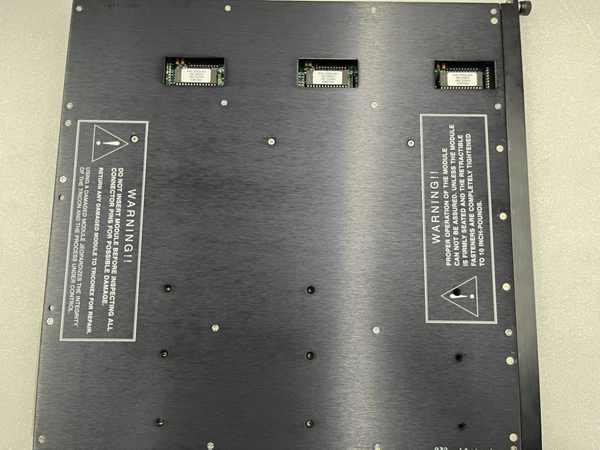

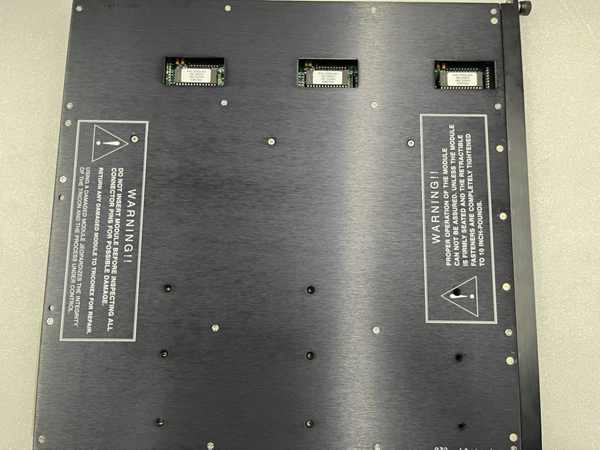

TRICONEX 3703E is a high-reliability analog input module designed for critical industrial control systems, particularly within TRICONEX’s Tricon family of safety controllers. Engineered to meet the demands of safety instrumented systems (SIS) in hazardous environments, the 3703E accurately measures and processes analog signals from field devices such as transmitters, sensors, and transducers. This module features TRICONEX’s TriStationary Redundancy (TMR) architecture, ensuring fault tolerance and continuous operation even in the presence of component failures. The 3703E is ideal for applications requiring precise signal conditioning, noise immunity, and compliance with industry standards like IEC 61508, making it a cornerstone in industries such as oil and gas, chemical processing, and power generation.

2. Product Parameters

| Parameter | Description |

|---|---|

| Signal Types | Supports 4-20 mA current loops, 0-10 V DC voltage signals |

| Channels | 16 isolated analog input channels |

| Resolution | 16-bit analog-to-digital conversion |

| Accuracy | ±0.05% of full-scale reading |

| Input Range | 0-20 mA, 4-20 mA, 0-5 V DC, 1-5 V DC (configurable via software) |

| Redundancy | TMR (Triple Modular Redundancy) with self-diagnostic capabilities |

| Compatibility | Tricon CX, EX, and RX series controllers |

| Voltage Supply | 24 V DC ±10% (isolated from field signals) |

| Environmental Rating | Operating temperature: -40°C to +70°C; humidity: 5-95% non-condensing |

| Certifications | IEC 61508 (SIL 3), FM, CSA, ATEX (for hazardous areas) |

TRICONEX 3703E

3. Advantages and Features

The TRICONEX 3703E stands out for its TMR architecture, which provides triple redundancy for each channel, ensuring that a single fault in one channel does not affect system integrity. Its advanced diagnostics continuously monitor channel health, with built-in self-test functions that achieve a diagnostic coverage (DC) rate exceeding 99%, minimizing undetected faults. The module’s high noise immunity (EMC/EMI compliance) and wide temperature range make it suitable for harsh industrial environments. For example, in a refinery’s distillation unit, the 3703E reliably processed temperature and pressure signals from field devices, maintaining control accuracy within ±0.1% even during power surges, thanks to its robust surge protection circuitry.

4. Application Areas and Case Studies

The TRICONEX 3703E is widely deployed in safety-critical processes across industries such as:

- Oil and Gas: Monitoring pressure, flow, and level in upstream production and downstream refining.

- Chemical Manufacturing: Controlling reactor temperatures and chemical concentrations in batch processes.

- Power Generation: Managing steam turbine parameters and boiler control systems.

Case Study: A major LNG plant integrated the 3703E into its Tricon SIS to monitor cryogenic pump temperatures. The module’s TMR redundancy allowed continuous operation during routine maintenance of individual channels, eliminating the need for system shutdowns. This resulted in a 40% reduction in maintenance downtime and improved overall plant availability.

5. Competitor Comparison

Compared to non-redundant analog input modules, the TRICONEX 3703E offers superior fault tolerance through its TMR design, making it unmatched in applications requiring SIL 3 compliance. Unlike generic modules with limited diagnostic capabilities, the 3703E provides detailed fault reporting and self-test features, reducing mean time to repair (MTTR). Its wide input range flexibility and built-in signal conditioning also eliminate the need for external signal conditioners, simplifying system design and reducing costs compared to fragmented solutions.

TRICONEX 3703E

6. Selection Recommendations

When selecting the TRICONEX 3703E, consider:

- Safety Integrity Level (SIL) Requirements: Ensure it aligns with your system’s SIL 2 or SIL 3 certification needs.

- Signal Type and Range: Match the module’s configurable input ranges to your field devices (e.g., 4-20 mA for transmitters).

- Redundancy Needs: Evaluate if TMR redundancy is critical for your application’s availability requirements.

- Environmental Conditions: Confirm compatibility with temperature, humidity, and vibration levels in your installation site.

7. Precautions

- Wiring Isolation: Use shielded twisted-pair cables to minimize electromagnetic interference (EMI) and follow TRICONEX’s grounding guidelines.

- Software Configuration: Properly configure input ranges and scaling parameters in the Tricon configuration software to avoid signal misinterpretation.

- Maintenance: Schedule periodic diagnostics checks to validate self-test functionality and ensure compliance with safety audits.

- Spare Parts Management: Maintain spare 3703E modules to facilitate quick replacement in case of faults, reducing downtime in critical systems.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.