Description

1. Product Description

2. Product Parameters

| Parameter | Description |

|---|---|

| Input Channels | 16 isolated analog input channels (configurable for voltage/current signals) |

| Signal Types | 4–20 mA current, 0–10 VDC voltage, RTD, thermocouple (via optional modules) |

| Resolution | 16-bit analog-to-digital conversion with ±0.1% accuracy |

| Redundancy | TMR architecture with self-diagnostic and fault voting capabilities |

| Update Rate | <10 ms per channel (typical) |

| Operating Temperature | -40°C to 70°C (-40°F to 158°F) |

| Certifications | SIL 3 compliant (IEC 61508), ATEX/IECEx for hazardous areas |

| Dimensions | [X] mm (W) × [X] mm (H) × [X] mm (D) (rack-mountable design) |

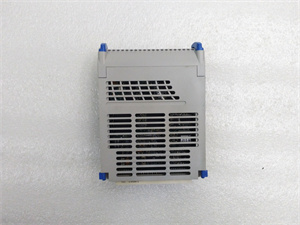

TRICONEX 8305A

3. Advantages and Features

4. Application Areas and Use Cases

- Oil and Gas: Monitoring pressure, temperature, and flow rates in refineries and offshore platforms.

- Power Generation: Capturing analog data from turbines, boilers, and generators in power plants.

- Chemical Processing: Controlling reactor conditions and material levels in production lines.

5. Competitive Comparison

Compared to non-redundant analog input modules, the 8305A offers superior safety integrity with its SIL 3 certification and TMR architecture, reducing the risk of undetected faults by over 90%. Its wide signal compatibility (supporting multiple sensor types without additional hardware) outperforms single-purpose modules, simplifying inventory management. The module’s real-time diagnostics and hot-swappable design also provide operational advantages over legacy systems, which often require manual calibration and system shutdowns for maintenance.

TRICONEX 8305A

6. Selection Recommendations

- Signal Requirements: Ensure the module supports the sensor types (e.g., RTD, thermocouple) and signal ranges in your application.

- Redundancy Needs: Evaluate whether TMR is necessary for your safety integrity level (SIL) requirements.

- Channel Density: Match the number of input channels to your system’s monitoring needs (e.g., 16 channels for medium-scale applications).

- Environmental Conditions: Confirm the module’s temperature and vibration ratings for harsh industrial settings.

7. Precautions

- Electrical Isolation: Ensure proper grounding and shielding to prevent noise interference with analog signals.

- Hot-Swap Procedure: Follow TRICONEX’s guidelines for safe module replacement to avoid data corruption or system disruptions.

- Calibration: Regularly verify channel accuracy using TRICONEX’s recommended tools and procedures (e.g., annual calibration checks).

- Firmware Updates: Keep the module’s firmware up to date to benefit from the latest diagnostics and compatibility improvements.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.