Description

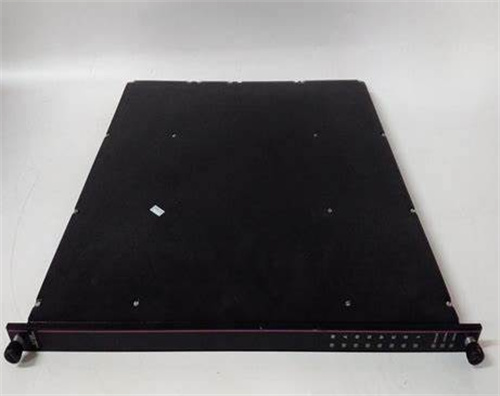

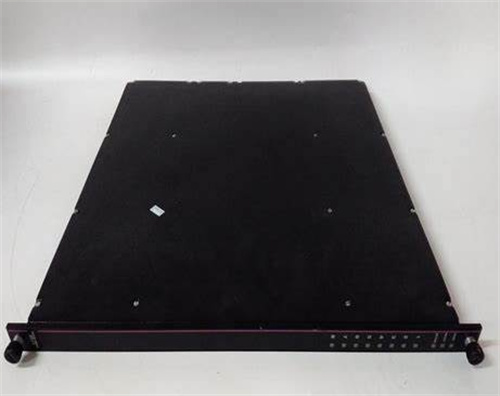

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Modular Processor Module (TMR-based) |

| Processing Core | Dual-core ARM Cortex-A9 with real-time OS |

| Memory | 2 GB RAM, 8 GB flash storage |

| Data Processing Rate | Up to 100,000 I/O operations per second |

| Redundancy | Triple modular redundancy (TMR) with auto-voting mechanism |

| Communication Interfaces | Ethernet (10/100/1000 Mbps), RS-232/485, USB 2.0 |

| Compatibility | TRICONEX Tricon V9/V10 systems, compatible with I/O modules and HMIs |

| Operating Temperature | -40°C to +65°C (-40°F to +149°F) |

| Certifications | SIL 3 (IEC 61508), ATEX, IECEx (hazardous area approval) |

TRICONEX MP6004

3. Advantages and Features

4. Application Fields and Cases

- Oil and Gas: Platform control systems, pipeline automation, and emergency shutdown (ESD) systems.

- Chemical Processing: Batch control, reactor safety systems, and continuous process optimization.

- Power Generation: Turbine control, boiler safety, and grid integration for renewable energy plants.

5. Competitor Comparison

Compared to non-TMR processor modules, the TRICONEX MP6004 offers inherent hardware redundancy without external failover mechanisms, reducing complexity and cost. Its dual-core architecture provides higher processing throughput than single-core alternatives, while support for diverse communication protocols (e.g., OPC UA, Modbus) enhances integration with legacy and modern systems. The module’s extended temperature range and hazardous area certifications also make it more robust for harsh industrial environments.

TRICONEX MP6004

6. Selection Suggestions

- System Scale: Ensure the module’s I/O capacity and processing speed match the complexity of your control logic (e.g., small-scale vs. large distributed systems).

- Redundancy Needs: Verify if TMR architecture aligns with your safety integrity level (SIL) requirements and tolerance for single-point failures.

- Communication Requirements: Check compatibility with existing fieldbus systems (e.g., Profibus, Ethernet/IP) and integration needs with supervisory control and data acquisition (SCADA) systems.

- Future Scalability: Evaluate whether the module supports firmware upgrades and expansion options for future system enhancements.

7. Precautions

- Installation: Follow TRICONEX’s guidelines for proper airflow and heat dissipation to maintain optimal operating temperatures.

- Firmware Management: Regularly update firmware to address security patches and performance improvements, using validated procedures to avoid downtime.

- Wiring Practices: Use shielded cables and isolated power supplies for communication interfaces to minimize electromagnetic interference (EMI).

- Testing: Conduct periodic functional safety tests (e.g., proof testing) to ensure compliance with SIL requirements and validate fault detection mechanisms.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.