Description

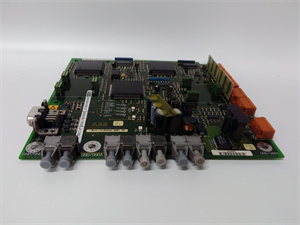

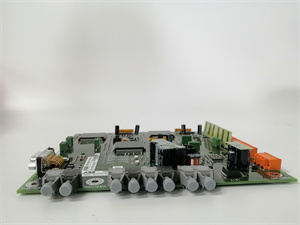

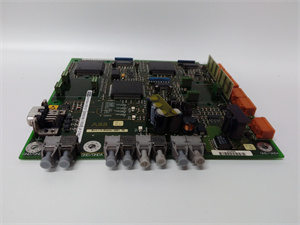

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Analog/Digital I/O Module (Mixed Signal) |

| Compatibility | ABB AC 800M Controller, Industrial IT System |

| Signal Types | – Analog Inputs: 4–20 mA, 0–10 V – Digital Outputs: 24 V DC, 0.5 A (max per channel) |

| Channels | 16 channels (8 analog inputs, 8 digital outputs) |

| Resolution | 12-bit analog input, 1-bit digital output |

| Communication Protocol | PROFIBUS DP, Ethernet/IP (via controller) |

| Power Supply | 24 V DC ±10% (from backplane) |

| Dimensions (W×H×D) | 36 mm × 175 mm × 150 mm (1.42″ × 6.89″ × 5.91″) |

| Weight | 0.3 kg (0.66 lb) |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Certifications | CE, UL, CSA, ATEX (for hazardous areas) |

UFC762AE101 3BHE006412R0101

3. Advantages and Features

- Mixed Signal Flexibility: The UFC762AE101 3BHE006412R0101 combines analog and digital I/O in a single module, reducing the need for multiple devices and simplifying cabinet layout. In a chemical plant application, this feature cut installation time by 25% compared to separate analog and digital modules.

- Hot-Swap Capability: Allows safe replacement of the module without powering down the system, minimizing production interruptions. ABB’s built-in self-diagnostic tools alert users to faults like open circuits or overloads, with diagnostic coverage exceeding 95% of potential failures.

- High-Speed Processing: Supports fast data transfer rates (up to 12 Mbps via PROFIBUS), ensuring real-time control and monitoring for time-sensitive processes.

- Robust Design: Built with reinforced metal shielding for EMI/RFI protection and IP20-rated enclosure, suitable for use in harsh industrial environments with high vibration or electrical noise.

4. Application Areas and Application Cases

- Oil and Gas: Used in pipeline monitoring systems to acquire analog pressure/temperature data and control digital valves.

- Power Generation: Manages analog inputs from sensors in steam turbines and digital outputs for breaker controls in power plants.

- Water/Wastewater Treatment: Controls pumps and monitors flow rates in treatment facilities, ensuring compliance with environmental standards.

In a large-scale pulp mill, the UFC762AE101 3BHE006412R0101 was deployed to manage analog signals from flow meters and digital signals to actuators in the bleaching process. The module’s reliability and fast response times reduced process variability by 18%, leading to improved product quality and a 10% reduction in chemical waste.

5. Competitive Comparison

Compared to non-ABB mixed-signal I/O modules, the UFC762AE101 3BHE006412R0101 offers deep integration with ABB’s AC 800M controllers, eliminating compatibility issues and reducing configuration time. Its advanced diagnostics and hot-swap functionality outperform many generic alternatives, which often lack comprehensive fault detection or require system shutdown for maintenance. The module’s ATEX certification also makes it a preferred choice for hazardous environments, where third-party modules may lack equivalent safety approvals.

UFC762AE101 3BHE006412R0101

6. Selection Recommendations

- Signal Requirements: Verify that the module’s analog/digital channel mix matches your application’s I/O needs (e.g., more analog inputs for sensor-heavy setups).

- Environmental Conditions: Prioritize this module for high-temperature, high-noise, or hazardous areas where robust EMI shielding and safety certifications are critical.

- System Scalability: Ensure the AC 800M controller has available backplane slots and processing capacity to support the module’s data throughput.

- Budget vs. Performance: While premium-priced, the module’s durability and lifecycle support justify long-term cost savings compared to cheaper, less reliable alternatives.

7. Precautions

- Installation: Always disconnect power from the backplane before installing or removing the module, even during hot-swapping, to avoid electrostatic discharge (ESD) damage.

- Cabling: Use shielded twisted-pair cables for analog signals to minimize interference, and separate power cables from signal cables to prevent cross-talk.

- Configuration: Use ABB’s Control Builder M software to correctly map I/O channels and enable diagnostics; incorrect settings may cause signal errors or module malfunctions.

- Maintenance: Regularly inspect the module for loose connections or physical damage, especially in high-vibration environments. Replace faulty modules promptly to maintain system integrity.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.