Description

1. Product Description

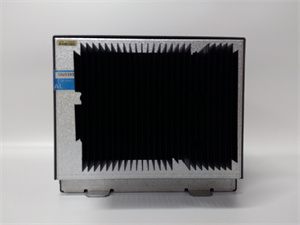

The ABB 1TGE120021R0010 is a high-reliability redundant control system designed for industrial automation, integrating advanced processing and fault tolerance for critical applications. As part of ABB’s industrial control portfolio, the 1TGE120021R0010 features dual 414-4H CPUs with 50MB memory, redundant power supplies, and CP443 network interface cards (NICs), enabling seamless failover between primary and backup controllers. It supports hot-pluggable modules and remote I/O via PROFIBUS, making it suitable for distributed control systems (DCS) in industries such as manufacturing, energy, and chemical processing. The system includes 7 built-in communication ports (Ethernet, local expansion, and remote I/O), USB programming, and data logging capabilities, ensuring flexibility and ease of integration.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | 1TGE120021R0010 |

| Type | Redundant Control System |

| Voltage | 24V DC (control), 120–230V AC (power supply) |

| Current | 5A (system operation) |

| CPU | Dual 414-4H CPUs (50MB memory, fast scan time) |

| Communication Ports | 7 ports (Ethernet, PROFIBUS, local/remote I/O) |

| Redundancy | Hot standby with automatic failover (CPU, power supply, communication) |

| I/O Configuration | Remote I/O via ET200M stations (PROFIBUS redundant bus) |

| Compatibility | ABB Advant Controller systems, Siemens S7-200 PLC (via EM277 gateway) |

| Dimensions | 482 mm (W) × 175 mm (H) × 250 mm (D) |

| Weight | 8.5 kg |

| Operating Temperature | 0–60°C |

1TGE120021R0010

3. Advantages and Features

- Redundancy Excellence: Dual CPUs, power supplies, and PROFIBUS buses ensure zero downtime during faults (e.g., CPU failure, communication loss).

- High Performance: 50MB memory and fast scan time enable real-time control for complex processes.

- Flexible Architecture: Remote I/O stations (ET200M) reduce cabling and support distributed installations.

- Ease of Maintenance: Hot-pluggable modules and diagnostic indicators (fault codes, communication status) simplify troubleshooting.

- Multi-Industry Compliance: Certified for use in hazardous environments (e.g., gas, chemical processing) with robust EMI/EMC protection.

4. Application Areas and Case Studies

- Industries: Steel manufacturing, thermal/hydro/nuclear power generation, oil/gas, chemical processing, and water treatment.

- Use Cases:

- Power Plants: Redundant control of turbine generators, ensuring continuous operation during maintenance.

- Chemical Plants: Monitoring reactor processes with fail-safe switching between controllers.

- Case Study: A petrochemical facility reduced unplanned outages by 35% using the 1TGE120021R0010 for redundant control of distillation units. The system’s automatic failover prevented production stops during CPU upgrades.

5. Competitor Comparison

Compared to standard single-controller systems, the 1TGE120021R0010 offers superior redundancy (dual CPUs/power supplies) and native integration with ABB/Siemens ecosystems. Its 7 communication ports and PROFIBUS redundancy outperform 竞品 with limited expandability, while hot-swappable modules reduce maintenance time by 50% versus non-modular solutions.

1TGE120021R0010

6. Selection Recommendations

- System Requirements: Verify compatibility with your DCS/PLC (e.g., ABB Advant, Siemens S7-200).

- I/O Needs: Configure remote I/O stations (ET200M) based on analog/digital channel counts.

- Environment: Ensure operating temperature (0–60°C) and voltage (24V DC) match site conditions.

- Budget: Balance redundancy needs (dual vs. single controller) against long-term reliability ROI.

7. Precautions

- Installation: Ground the control cabinet to prevent static discharge; follow ABB’s wiring guidelines for PROFIBUS redundancy.

- Maintenance: Regularly update firmware and test failover procedures (quarterly recommended).

- Fault Handling: Use diagnostic tools (e.g., CPU status LEDs) to identify issues (e.g., communication errors, power supply faults).

- Calibration: Recalibrate touch screens (if integrated) using ABB’s calibration utility to maintain accuracy.