Description

1. Product Description

The 3BHB000272R0001 UFC719AE01 is a high-performance frequency converter module designed by ABB, a globally recognized leader in industrial automation. Engineered for precise motor control and system optimization, this module integrates advanced power electronics and digital control technology to deliver reliable operation in diverse industrial environments. The 3BHB000272R0001 UFC719AE01 supports seamless integration with ABB’s industrial control systems (e.g., AC500, AC800M), offering flexible configuration for speed regulation, energy efficiency, and process optimization. ABB’s 3BHB000272R0001 UFC719AE01 is ideal for applications requiring robust performance, including motor drives, conveyor systems, and pump/fan control. Its compact design, multi-protocol compatibility, and built-in safety features make it a versatile choice for upgrading or building new automation setups.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 380–500 V AC (±10%), 24 V DC (control) |

| Rated Current | 16 A (continuous), 20 A (peak) |

| Power Rating | 7.5 kW |

| Control Method | Vector control, direct torque control (DTC) |

| Communication Interfaces | Profibus DP, Modbus RTU, Ethernet/IP |

| Motor Compatibility | 3-phase induction/synchronous motors |

| Protection Class | IP20 (module), IP54 (with optional enclosure) |

| Operating Temperature | -10°C to +50°C (ambient) |

| Certifications | CE, UL, RoHS, ISO 9001 |

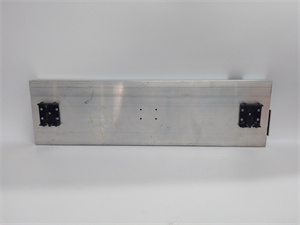

3BHB000272R0001 UFC719AE01

3. Advantages and Features

- High Reliability: With an MTBF exceeding 80,000 hours, the 3BHB000272R0001 UFC719AE01 ensures long-term stability in harsh conditions (e.g., dust, temperature fluctuations).

- Energy Efficiency: Reduces energy consumption by up to 30% compared to fixed-speed systems through variable torque control.

- Advanced Control: DTC technology enables precise speed regulation (±0.1% accuracy) and quick response to load changes.

- Flexible Integration: Supports multiple communication protocols and integrates with ABB’s System 800xA for centralized monitoring.

- Safety Features: Built-in overvoltage/overcurrent protection, short-circuit immunity, and emergency stop functionality.

4. Application Areas and Case Studies

Industry Applications:

- Manufacturing (machine tools, conveyor systems)

- Energy (pump stations, HVAC systems)

- Water treatment (pump control)

- Material handling (cranes, lifts)

Case Study:

A North American water treatment plant upgraded its pump system with the 3BHB000272R0001 UFC719AE01. By adjusting pump speed based on water demand, the module reduced energy costs by 25% and extended motor lifespan by 40% through soft start/stop functionality.

A North American water treatment plant upgraded its pump system with the 3BHB000272R0001 UFC719AE01. By adjusting pump speed based on water demand, the module reduced energy costs by 25% and extended motor lifespan by 40% through soft start/stop functionality.

5. Competitive Comparison

Compared to similar frequency converter modules:

- Faster Response: 5 ms torque response (vs. industry average of 10–15 ms).

- Broader Voltage Range: 380–500 V AC (vs. typical 400–480 V).

- Integrated Safety: Built-in STO (Safety Torque Off) compliance (ISO 13849 PL d) without additional modules.

- Compact Design: 30% smaller footprint than comparable 7.5 kW drives.

3BHB000272R0001 UFC719AE01

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing ABB control systems (e.g., AC500 I/O modules).

- Power Requirements: Match motor power (7.5 kW max.) and voltage (3-phase AC).

- Environment: Choose optional IP54 enclosure for dusty/wet environments.

- Functionality: Prioritize DTC control for high-precision applications (e.g., robotics); select vector control for general use.

7. Precautions

- Installation: Mount vertically in a well-ventilated enclosure; torque terminal screws to 4 N·m.

- Wiring: Use shielded cables for control signals; separate power/control wiring to prevent interference.

- Commissioning: Calibrate motor parameters (voltage, impedance) via ABB’s DriveWindow software.

- Maintenance: Clean dust from vents annually; replace cooling fans every 5 years (expected lifespan).