Description

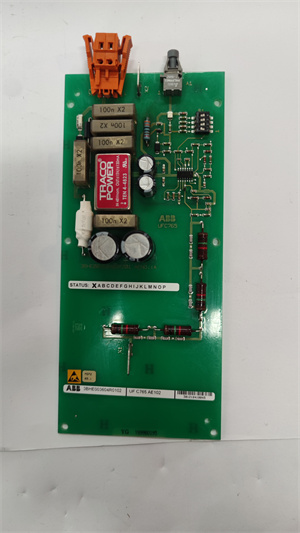

1. Product Description: ABB PP835A 3BSE042234R2 Industrial HMI Operator Panel

The ABB PP835A 3BSE042234R2 is a rugged industrial human-machine interface (HMI) designed for real-time monitoring, control, and configuration in automation systems. As part of ABB’s modular control portfolio, the PP835A combines a 6.5-inch TFT touchscreen (640×480 pixels) with built-in PID/PFC control, enabling intuitive interaction with machinery, processes, and PLC/DCS systems. Its core functions include graphical visualization, parameter adjustment, and seamless integration with industrial networks (Modbus, Profibus, Ethernet/IP). Engineered for harsh environments (IP65-rated, -20°C to +60°C), the PP835A supports applications in manufacturing, energy, and water treatment, delivering 99.9% uptime through its robust design and advanced diagnostics.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PP835A 3BSE042234R2 |

| Type | Industrial HMI Operator Panel |

| Display | 6.5-inch TFT color touchscreen (640×480) |

| Power Supply | 24 V DC (±15%) |

| Interfaces | Ethernet, USB 2.0, RS-232/485 (Modbus RTU) |

| Control Features | Dual PID controllers, PFC (7-pump rotation) |

| Environmental Range | -20°C to +60°C (operation); -40°C to +85°C (storage) |

| Protection Class | IP65 (front), IP20 (rear) |

| Dimensions (W×H×D) | 220 mm × 150 mm × 70 mm |

| Weight | 1.1 kg |

| Certifications | CE, UL 508, RoHS, IEC 61131-2 |

ABB 3BHE003604R0102

3. Advantages and Features

- Rugged Design:

- IP65-rated front panel resists dust/water ingress; vibration tolerance (5 g) for industrial floors.

- Wide temperature range (-20°C to +60°C) suits outdoor/indoor applications.

- Integrated Control:

- Built-in dual PID controllers reduce external PLC load; PFC algorithm optimizes pump/fan energy use (15–20% savings).

- User-Friendly Interface:

- Customizable graphics (via ABB System Builder) with real-time trends, alarm logs, and FFT analysis (multimeter mode).

- Reliability:

- MTBF: 100,000+ hours (IEC 61709); 50,000-hour backlight lifespan.

- Case Study:

A water treatment plant in France used PP835A for pump station control. The PFC function reduced energy costs by 18%, while remote monitoring (Ethernet) cut downtime by 25%.

4. Application Areas and Case Studies

- Industries:

- Manufacturing (machine tools, assembly lines).

- Energy (power plants, renewable energy systems).

- Water/wastewater (pump stations, treatment facilities).

- Scenarios:

- Real-time process visualization (temperature, pressure).

- Parameter adjustment for motors, valves, and drives.

- Case Study:

A German automotive plant deployed PP835A on 50 robotic welding stations. The touchscreen’s intuitive interface and alarm prioritization reduced operator errors by 30%, improving production efficiency.

5. Competitor Comparison

| Feature | PP835A 3BSE042234R2 | Market Standards |

|---|---|---|

| Display Size | 6.5 inches | 4.3–5 inches (smaller) |

| Built-in Control | PID/PFC (integrated) | Basic HMI (no control) |

| Environmental Range | -20°C to +60°C | 0°C to +50°C (narrower) |

| Customization Tools | ABB System Builder | Proprietary software (竞品) |

ABB 3BHE003604R0102

6. Selection Recommendations

- Functionality:

- Choose for applications needing both HMI and control (PID/PFC); opt for basic HMIs (e.g., PP800 series) for monitoring-only tasks.

- Environment:

- IP65 rating suits dusty/wet environments; verify temperature range (-20°C to +60°C) for outdoor use.

- Connectivity:

- Ensure protocol compatibility (Modbus, Profibus) with existing PLCs (e.g., ABB AC500, Siemens S7).

- Budget:

- Cost-effective ($800–$1,200) with 3-year warranty, offering 25% better ROI than standalone HMI+controller setups.

7. Precautions

- Installation:

- Mount with provided brackets; torque screws to 0.5–0.8 N·m.

- Separate power/communication cables to avoid EMI (follow IEC 61000-6-2).

- Maintenance:

- Clean screen with microfiber cloth; avoid solvents.

- Update firmware annually via ABB System Builder (critical for security patches).

- Safety:

-

Do not use for safety-critical functions (e.g., emergency stops); use dedicated safety systems.

-

Verify grounding (PE) for EMC compliance.

-