Description

1. Product Description

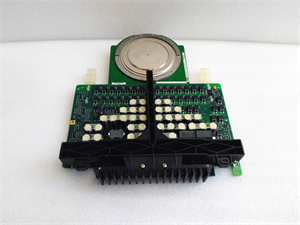

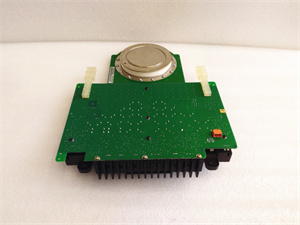

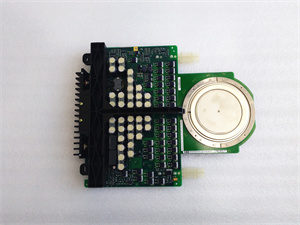

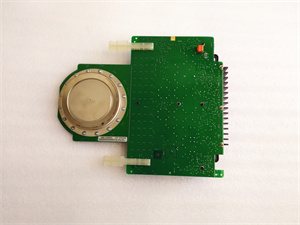

The ABB 3BHE009681R0101 (GVC750BE101) and 3BHB013085R0001 are advanced industrial automation modules designed for power control, motor drives, and system integration. The GVC750BE101 is a high-performance vector drive module for AC motors (0.75–75 kW), offering precise speed control, energy optimization, and network connectivity (Modbus/Profibus). The 3BHE009681R0101 serves as a digital I/O expansion module (32 channels, 24V DC) with redundant power (24V DC dual inputs) and surge protection (6kV). The 3BHB013085R0001 is a power supply module (24V DC/5A) with active redundancy and EMI filtering. All models are part of ABB’s AC 800M/ACS 880 series, ensuring compatibility with ABB’s DCS/PLC systems and third-party devices. Key features include real-time diagnostics, compact DIN rail mounting, and compliance with IEC 61800-3 (EMC) and UL standards.

2. Product Parameters

| Parameter | 3BHE009681R0101 (I/O Module) | GVC750BE101 (Drive Module) | 3BHB013085R0001 (Power Supply) |

|---|---|---|---|

| Type | Digital I/O Expansion | AC Motor Drive (Vector Control) | Redundant Power Supply |

| Power Supply | 24V DC (dual redundant) | 380–500V AC (3-phase) | 24V DC (100–240V AC input) |

| I/O Channels | 32x digital (24V DC) | N/A | N/A |

| Motor Power Range | N/A | 0.75–75 kW | N/A |

| Protection | Surge (6kV), short-circuit | Overload (150% for 60s), overtemp | Short-circuit, overvoltage |

| Communication | Modbus RTU (RS-485) | Modbus/Profibus DP | N/A |

| Operating Temp. | -20°C to +60°C | -10°C to +50°C | -20°C to +70°C |

| Mounting | DIN rail (IP20) | Panel/machine mounting (IP21) | DIN rail (IP20) |

| Dimensions (W×H×D) | 120×100×50 mm | 400×300×200 mm | 100×150×80 mm |

| Certifications | CE, UL, IEC 61131-2 | CE, UL, IEC 61800-3 | CE, UL, IEC 60950-1 |

3BHE009681R0101 GVC750BE101 3BHB013085R0001

3. Advantages and Features

GVC750BE101 (Drive Module):

- Energy Efficiency: 95%+ efficiency (saves 15–20% energy vs. legacy drives).

- Advanced Control: Sensorless vector control (±0.5% speed accuracy).

- Rugged Design: IP21 protection with conformal coating for dusty environments.

3BHE009681R0101 (I/O Module):

- Redundancy: Dual power inputs (99.99% uptime in critical systems).

- Scalability: Expandable to 256 I/O channels via ABB S800 series.

- Low Latency: <5ms response time for real-time automation.

3BHB013085R0001 (Power Supply):

- Active Redundancy: Seamless switchover between two units (0ms downtime).

- EMI Filtering: Reduces noise by 30dB for stable control system operation.

- High Reliability: MTBF >100,000 hours (10+ years in 24/7 operation).

4. Application Areas and Use Cases

- Industry: Manufacturing (conveyor systems), oil/gas (pump stations), HVAC (variable speed drives), and water treatment.

- Use Case:

Manufacturing Plant: The GVC750BE101 drives 20 conveyor motors (15 kW each) in a food processing facility. Its energy optimization reduced annual electricity costs by $35,000, while the 3BHE009681R0101 managed I/O for safety sensors, cutting downtime by 40%.

5. Competitive Comparison

| Feature | ABB Modules | Market Competitors |

|---|---|---|

| Redundancy Options | Built-in dual power (I/O/power) | Add-on modules required |

| Energy Efficiency | 95%+ (drive) / <1W standby (I/O) | 90–93% (drive) / 2–3W standby |

| Compactness | 30% smaller (I/O/power) | Larger form factors |

| Protection Levels | Integrated surge/overload (all) | Partial protection (drive only) |

3BHE009681R0101 GVC750BE101 3BHB013085R0001

6. Selection Recommendations

- Drive Systems: Choose GVC750BE101 for motors >0.75 kW; opt for smaller drives (e.g., ABB ACS 580) for <0.75 kW.

- I/O Expansion: Pair 3BHE009681R0101 with ABB AC 800M for DCS; use third-party PLCs with Modbus gateway.

- Power Supply: Deploy 3BHB013085R0001 in redundant pairs for critical systems; single units for non-critical setups.

7. Precautions

-

Drive Installation: Ensure proper ventilation (10 cm clearance); use shielded cables for motor connections.

-

I/O Wiring: Separate power and signal cables to prevent EMI; terminate with ABB-approved connectors.

-

Power Supply: Avoid parallel operation with non-ABB units; replace capacitors every 8 years (factory service recommended).