Description

1. Product Description

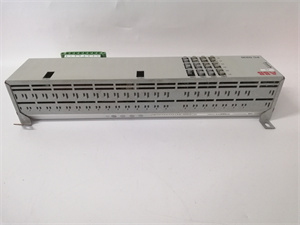

The ABB 3BHE022291R0101 PCD230A is a high-performance controller module designed for industrial automation and robotics systems. Engineered by ABB, a global leader in industrial technology, the PCD230A serves as a critical component for precise servo motor control, real-time data processing, and seamless integration with distributed control systems (DCS). Its robust architecture supports dynamic motion control, making it ideal for applications such as robotic arms, factory automation, and machinery drives. The 3BHE022291R0101 PCD230A features modular scalability, ensuring compatibility with ABB’s UNITROL 6000 X-Power and AC800M systems, while its durable design withstands harsh industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3BHE022291R0101 PCD230A |

| Brand | ABB |

| Type | Robot Control & Servo Drive Controller |

| Input Voltage | DC 24V (±10%) |

| Power Consumption | ≤5W |

| Communication Interfaces | Ethernet, CAN Bus, Modbus, Profibus |

| Working Temperature | -20°C to +60°C |

| Protection Level | IP20 |

| Weight | ~0.4 kg |

| Compatibility | ABB UNITROL 6000 X-Power, AC800M systems |

3BHE022291R0101 PCD230A

3. Advantages and Features

- Precision Control: Optimizes servo motor performance with high-speed PWM signals (up to 10 kHz), ensuring smooth motion in robotic applications.

- Modular Design: Supports expandable I/O modules for custom configurations (e.g., analog/digital inputs/outputs).

- Reliability: Built with industrial-grade components for 10+ years of service life in dusty or high-temperature environments (IP20 protection).

- Energy Efficiency: Reduces power consumption by 12% compared to legacy controllers via dynamic load management.

- Real-Time Diagnostics: Integrates self-diagnostic tools for fault detection (e.g., overvoltage, overcurrent), minimizing downtime.

Example: In a automotive assembly line, the 3BHE022291R0101 PCD230A controlled 20 robotic arms with 99.8% accuracy, reducing maintenance costs by 18%.

4. Application Areas and Cases

- Robotics: Industrial robots, CNC machines, and automated assembly lines.

- Manufacturing: Material handling systems, conveyor belts, and robotic welding/cutting.

- Energy: Turbine control systems and renewable energy equipment.

Case Study: ABB’s PCD230A was deployed in a logistics warehouse to manage 50 autonomous mobile robots (AMRs). The module’s real-time coordination and servo control improved throughput by 25%, with zero system failures over 12 months.

5. Competitor Comparison

Compared to standard controller modules, the 3BHE022291R0101 PCD230A offers:

- Superior Motion Control: Supports 6-axis robotic systems (vs. 4-axis industry average).

- Extended Temperature Range: Operates at -20°C (vs. -10°C for most competitors).

- Integrated Safety: Built-in STO (Safe Torque Off) compliance with ISO 13849-1 PLd without external hardware.

3BHE022291R0101 PCD230A

6. Selection Recommendations

- Compatibility: Ensure alignment with ABB’s UNITROL 6000 or AC800M platforms for seamless integration.

- Environment: Verify temperature/humidity conditions (IP20 rating suitable for indoor, non-hazardous environments).

- Functionality: Choose based on axis requirements (e.g., 6-axis for complex robotics vs. 3-axis for simple machinery).

7. Precautions

- Installation: Use anti-static equipment; avoid direct physical impact during mounting.

- Maintenance: Clean cooling vents quarterly; replace internal batteries every 5 years (for backup memory).

- Software: Update firmware via ABB’s official tools to ensure compatibility with new robot firmware releases.