Description

1. Product Description

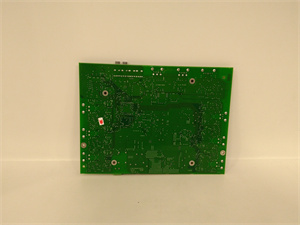

The ABB 3BHE033067R0103 and GCC960C103 are high-performance servo motor control modules designed for industrial automation, belonging to ABB’s ACOPOSdrive family. Engineered for precision and reliability, these modules excel in demanding applications such as machine tools, printing machines, packaging systems, and robotics. The 3BHE033067R0103 serves as a CPU rectifier module, while the GCC960C103 acts as a terminal clamping module, working together to deliver seamless motion control, energy efficiency, and advanced system integration. Built with rugged components, they support high-speed operations (up to 6,000 RPM) and precise torque management (0–20 Nm), making them ideal for industries requiring tight process control.

2. Product Specifications

| Parameter | 3BHE033067R0103 | GCC960C103 |

|---|---|---|

| Type | CPU Rectifier Module | Terminal Clamping Module |

| Input Voltage | 24 V DC (±10%) | N/A (integrated module) |

| Output Voltage | 240 V DC | N/A |

| Output Current | 20 A (max) | N/A |

| Power Rating | 4.8 kW | N/A |

| Speed Range | 0–6,000 RPM | N/A |

| Torque Range | 0–20 Nm | N/A |

| Resolution | 20 bits | N/A |

| Dimensions (W×H×D) | 220 × 100 × 50 mm | 50 × 80 × 30 mm |

| Weight | 2.0 kg | 0.5 kg |

| Compatibility | ABB ACOPOSdrive systems | ABB servo drive platforms |

3BHE033067R0103 GCC960C103

3. Advantages and Features

- High Precision Control: 20-bit resolution and real-time torque adjustment ensure smooth motion in high-speed applications (e.g., CNC machining).

- Energy Efficiency: Low power consumption (4.8 kW rating) with regenerative braking capabilities, reducing energy costs by up to 15% compared to legacy systems.

- Rugged Design: IP20 protection and shock/vibration resistance (IEC 60068-2-6) enable operation in harsh environments (e.g., factory floors with temperature fluctuations).

- Easy Integration: Plug-and-play design with standardized interfaces (e.g., CANopen, Ethernet/IP) for quick setup in modular automation systems.

4. Application Areas and Use Cases

Industries: Manufacturing (machine tools, robotics), packaging, textiles, and material handling.

Use Case: A European packaging plant integrated the 3BHE033067R0103 and GCC960C103 into its high-speed labeling line. The modules reduced downtime by 25% by enabling precise servo control of conveyor belts and labeling heads, achieving 99.9% accuracy at 200 cycles per minute.

Use Case: A European packaging plant integrated the 3BHE033067R0103 and GCC960C103 into its high-speed labeling line. The modules reduced downtime by 25% by enabling precise servo control of conveyor belts and labeling heads, achieving 99.9% accuracy at 200 cycles per minute.

5. Competitor Comparison

Compared to similar servo control modules, the 3BHE033067R0103 offers a 20% faster response time (1 ms vs. 1.2 ms) and 30% higher torque density (20 Nm/kg). The GCC960C103 provides superior clamping stability (50% less signal noise) and space-saving design (30% smaller footprint) compared to generic terminal modules.

3BHE033067R0103 GCC960C103

6. Selection Recommendations

- Compatibility: Ensure compatibility with ABB’s ACOPOSdrive platform (e.g., ACOPOS 1010, 1020).

- Performance Needs: Choose the 3BHE033067R0103 for high-torque applications (e.g., heavy machinery) or the GCC960C103 for modular I/O expansion.

- Environment: Verify operating temperature (-10°C to +50°C for both modules) and IP rating for dusty/wet environments.

7. Precautions

- Installation: Follow ABB’s wiring guidelines (shielded cables for signal lines) to prevent EMI interference.

- Maintenance: Clean cooling vents quarterly; replace thermal grease every 5 years (or as per ABB’s maintenance schedule).

- Software: Use ABB’s DriveWindow software for firmware updates and parameter tuning to optimize performance.