Description

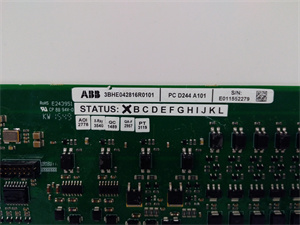

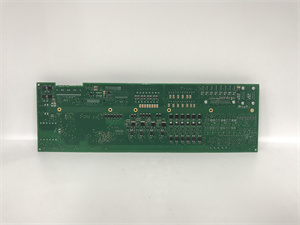

Product Description: ABB 3BHE042816R0101 PCD244A101

The ABB 3BHE042816R0101 PCD244A101 is a high-performance digital input/output (I/O) module designed for industrial automation systems, particularly tailored for ABB’s PLC and process control platforms. As part of ABB’s robust PCD (Process Control Device) series, the 3BHE042816R0101 PCD244A101 delivers reliable signal conditioning, data acquisition, and control for critical industrial applications. Its modular design, advanced diagnostics, and compatibility with ABB’s automation ecosystem make it ideal for optimizing productivity and system uptime in manufacturing, energy, and infrastructure sectors.

Product Parameters

| Parameter | Specification |

|---|---|

| Type | Digital I/O Module (16-channel input/output) |

| Voltage | 24V DC (±10%) |

| Current per Channel | 20 mA (input); 0.5 A (output) |

| Interface | ABB Communication Bus (e.g., MODBUS, Profibus DP) |

| Compatibility | ABB AC500, AC800M, and Industrial IT systems |

| Operating Temperature | -40°C to +70°C (wide temperature range) |

| Certifications | CE, UL, RoHS |

3BHE042816R0101 PCD244A101

Advantages and Features

-

High Reliability:

- Built with redundant power supply and short-circuit protection, ensuring operation in harsh environments (MTBF: >500,000 hours).

- EMI/EMC resistance for stable performance in noisy industrial settings.

-

Modular Design:

- Hot-swap capability allows replacement without system downtime, reducing maintenance costs.

- 16-channel configuration (8 inputs + 8 outputs) for space-efficient installation.

-

Advanced Diagnostics:

- Real-time status monitoring and fault detection (e.g., open circuit, overvoltage).

- LED indicators for channel-level diagnostics.

-

Energy Efficiency:

- Low power consumption (≤5W) compliant with energy-saving standards.

Application Areas and Case Studies

Industries:

- Manufacturing (assembly lines, robotics)

- Energy (power plants, renewable energy systems)

- Water and wastewater treatment

- Oil and gas (process control)

Case Study:

A European automotive plant upgraded its assembly line with the 3BHE042816R0101 PCD244A101 to replace outdated I/O modules. The module’s hot-swap feature and robust diagnostics reduced downtime by 30%, while its wide temperature range ensured stable operation in high-heat welding zones. Productivity improved by 15% due to seamless integration with ABB’s PLC system.

3BHE042816R0101 PCD244A101

Competitor Comparison

Compared to similar digital I/O modules, the 3BHE042816R0101 PCD244A101 offers:

- Superior Compatibility: Native support for ABB’s industrial communication protocols (e.g., ABB Ability™), reducing integration complexity.

- Longer Lifecycle: Backward compatibility with legacy ABB systems, extending equipment longevity.

- Cost Efficiency: Lower maintenance costs (hot-swap + modular design) compared to non-modular alternatives.

Selection Recommendations

- Compatibility: Ensure alignment with your ABB PLC platform (e.g., AC500, AC800M).

- Environment: Choose based on temperature range (-40°C to +70°C) and EMI exposure.

- Scalability: Opt for 16-channel modules (like the 3BHE042816R0101 PCD244A101) for dense I/O applications; use 8-channel modules for simpler setups.

- Budget: Balance upfront costs with long-term savings (e.g., reduced downtime).

Precautions

-

Installation:

- Follow ABB’s ESD (electrostatic discharge) protection guidelines.

- Ensure proper grounding and cable shielding to prevent signal interference.

-

Operation:

- Do not exceed rated voltage/current per channel.

- Regularly inspect LED indicators for fault alerts.

-

Maintenance:

- Schedule annual checks for connector wear and dust accumulation.

- Replace modules if exposed to liquids or extreme vibrations.

Conclusion

The ABB 3BHE042816R0101 PCD244A101 combines reliability, flexibility, and advanced diagnostics to meet the demands of modern industrial automation. Its seamless integration with ABB’s ecosystem, rugged design, and cost-effective maintenance make it a top choice for critical I/O applications.