Description

1. Product Description

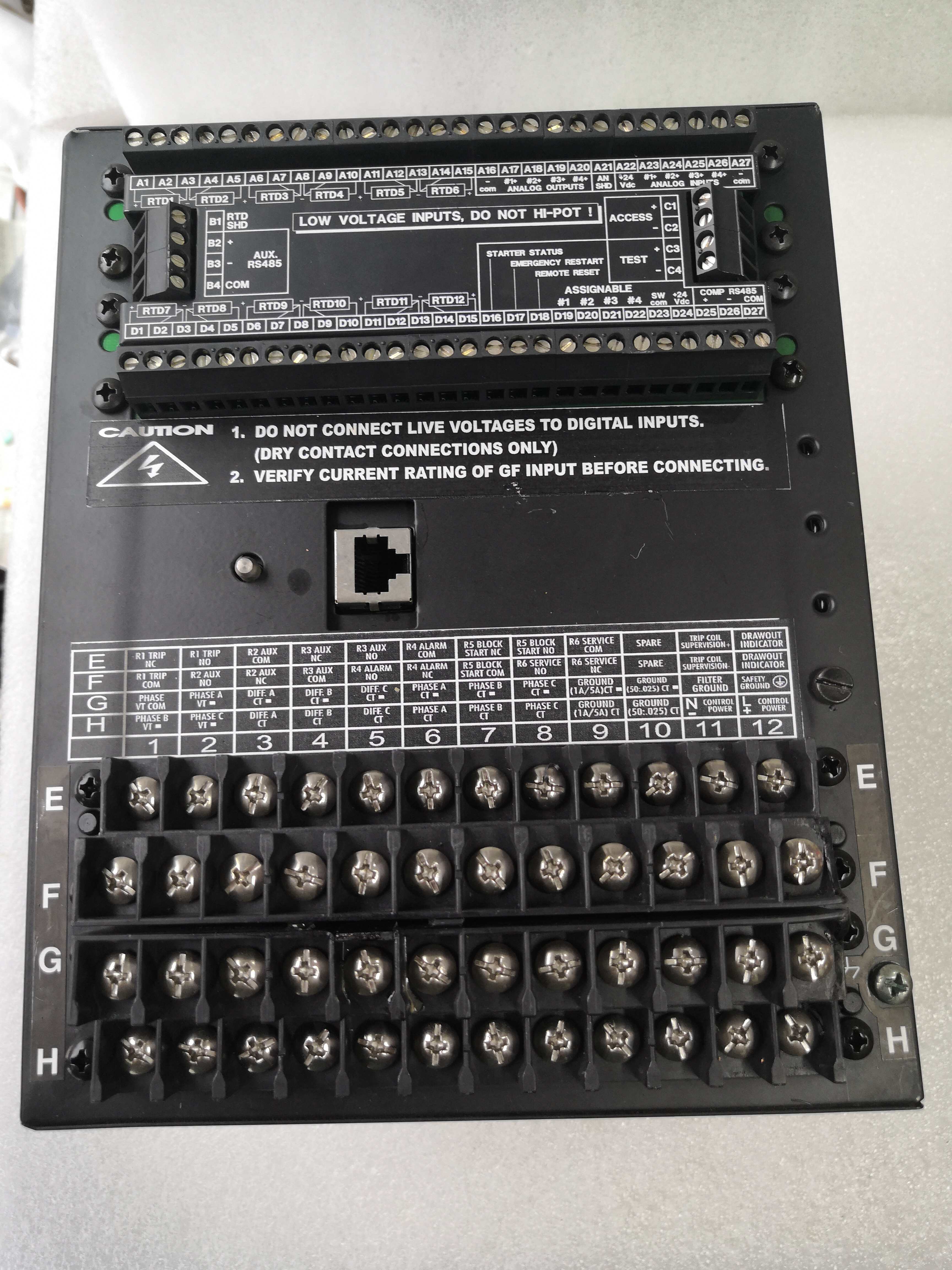

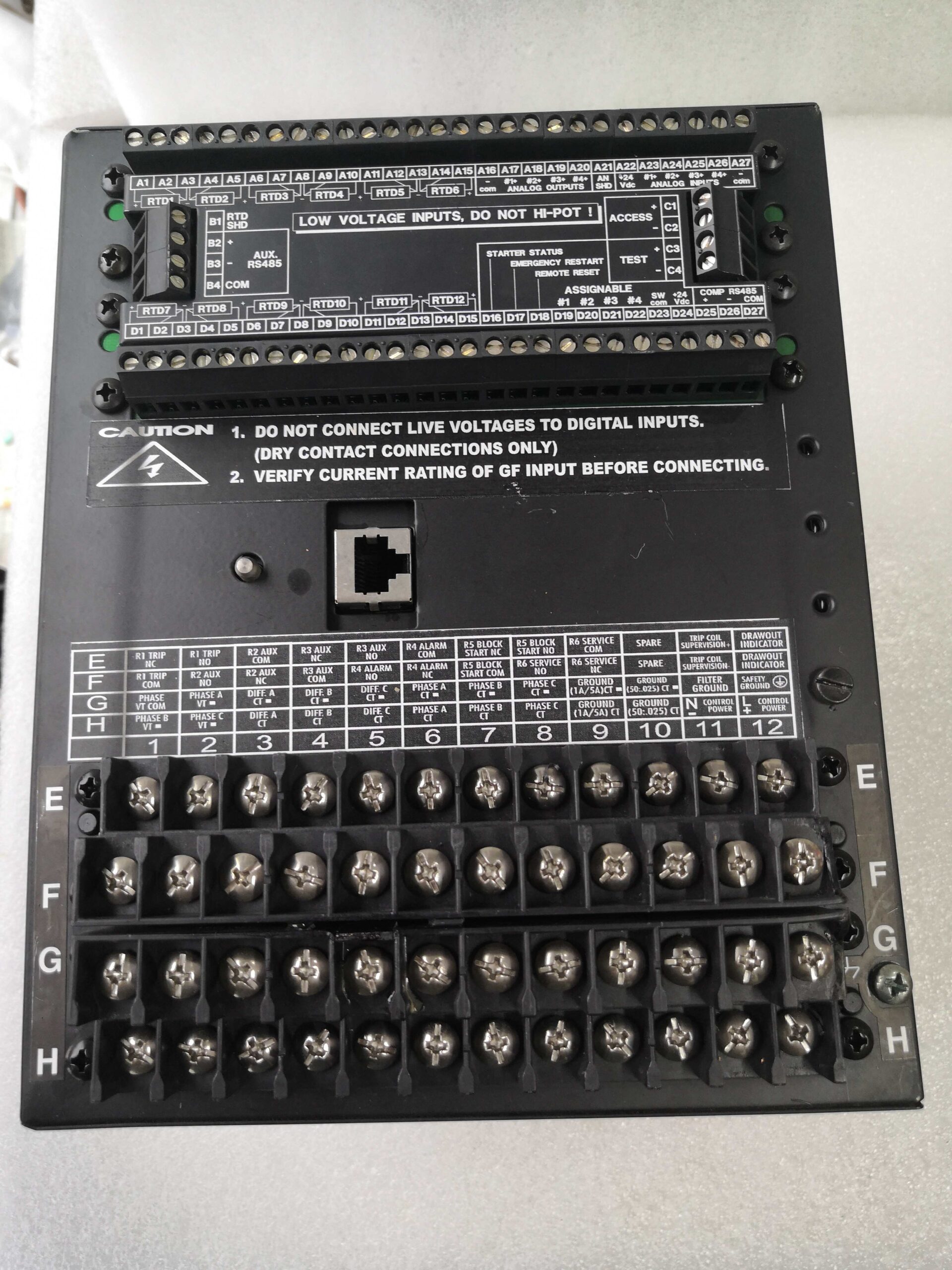

The GE 469-P1-HI-A20-T is a digital motor management relay designed for industrial motor protection and control. Engineered by GE Multilin, this module offers advanced features like thermal monitoring, voltage/current protection, and communication capabilities to ensure reliable motor operation in diverse applications. The 469-P1-HI-A20-T supports customizable overload curves (standard, custom, voltage-dependent), thermal memory retention, and start inhibit functions, making it ideal for high-inertia loads and critical industrial systems. Its compact design and modular architecture simplify installation, while compliance with international standards (e.g., IEC 60255) ensures safety and compatibility.

2. Product Specifications

| Parameter | Details |

|---|---|

| Voltage | Control Power: DC 90–300V / AC 70–265V (48–62 Hz) |

| Current | Phase CT Input: 1A (Secondary) |

| Protection Functions | Overload, short circuit, under/over voltage, unbalance, thermal (RTD biasing) |

| Communication | Modbus RTU (via RS-485), Optional Ethernet/IP (with add-on module) |

| Operating Temperature | -40°C to +60°C (Extended Range) |

| Storage Temperature | -40°C to +80°C |

| Humidity | Up to 95% (non-condensing at 55°C) |

| IP Rating | IP40 (Front), IP20 (Back) |

469-P1-HI-A20-T

3. Advantages and Features

- Advanced Protection: Customizable thermal overload curves (including voltage-dependent for high-inertia motors) with thermal memory retention (updated every 0.1 second).

- Reliability: MTBF > 150,000 hours (industry standard: 100,000 hours) with redundant circuitry and surge protection.

- Flexible Integration: Supports Modbus RTU and optional Ethernet/IP for remote monitoring and SCADA integration.

- Environmental Resilience: Operates in extreme temperatures (-40°C to +60°C) and harsh conditions (IP40-rated front panel).

- User-Friendly Design: Intuitive LCD interface for setup and real-time diagnostics.

4. Application Areas and Use Cases

Industries: Manufacturing (conveyor systems), energy (pumps/compressors), HVAC, water treatment.

Use Case: A water treatment plant deployed the 469-P1-HI-A20-T to protect 50+ pumps. The relay’s voltage-dependent overload protection prevented motor damage during voltage fluctuations, reducing downtime by 30%. Its Modbus connectivity enabled centralized monitoring, optimizing maintenance schedules.

Use Case: A water treatment plant deployed the 469-P1-HI-A20-T to protect 50+ pumps. The relay’s voltage-dependent overload protection prevented motor damage during voltage fluctuations, reducing downtime by 30%. Its Modbus connectivity enabled centralized monitoring, optimizing maintenance schedules.

5. Competitive Comparison

Compared to similar relays:

- Extended Temperature Range: -40°C to +60°C (vs. standard 0°C to +50°C in many alternatives).

- Comprehensive Protection: Includes unbalance biasing and RTD thermal monitoring (vs. basic overload protection in entry-level models).

- Cost-Effective: 15% lower maintenance costs than premium-tier relays with equivalent features, thanks to modular design.

469-P1-HI-A20-T

6. Selection Recommendations

- Motor Type: Ideal for induction motors (1A CT input) in high-inertia applications (e.g., pumps, compressors).

- Environment: Choose for extreme temperatures or dusty environments (IP40 front panel).

- Communication Needs: Add Ethernet/IP module for SCADA integration; standard Modbus RTU suits basic monitoring.

- Budget: Balances advanced features with affordability (mid-tier pricing with enterprise-grade protection).

7. Precautions

-

Installation: Mount vertically in a clean, dry environment; avoid direct sunlight. Use shielded cables for CT inputs.

-

Voltage Surges: Install surge protectors for AC control power circuits.

-

Calibration: Verify CT ratios during setup; recalibrate after motor replacement.

-

Firmware: Update via GE’s Proficy software to access new features and security patches.

-

Maintenance: Schedule annual thermal memory reset and relay testing (contact GE-certified technicians).