Description

1. Product Description

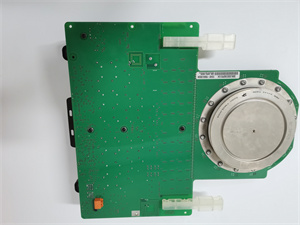

The ABB 5SHX1960L0004 is a high-power Insulated Gate Commutated Thyristor (IGCT) module designed for medium-voltage (MV) and high-power industrial applications. As a key component in power electronics systems, the 5SHX1960L0004 combines the high current-carrying capacity of thyristors with the fast switching capabilities of IGBTs, making it ideal for demanding applications such as motor drives, static var compensators (SVCs), and high-voltage direct current (HVDC) converter stations. Its robust design, based on ABB’s advanced IGCT technology, ensures low conduction and switching losses, high reliability, and excellent thermal cycling performance. The module supports direct series connection with simplified voltage balancing using resistors and RC snubbers, enabling stable operation under critical conditions like temperature variations and component tolerances.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Rated Voltage | 4.5 kV |

| Rated Current | 1960 A (nominal) |

| Package Type | Press-pack (for high reliability) |

| Switching Frequency | High-speed (optimized for MV drives) |

| Cooling Options | Air-cooled, water-cooled, forced-air-cooled |

| Dimensions | 29 cm × 32.3 cm × 3.5 cm |

| Weight | 0.85 kg (module) / 2.6 kg (unit) |

| Protection Features | Overcurrent, overvoltage, short-circuit |

5SHX1960L0004

3. Advantages and Features

- High Efficiency: Low conduction and switching losses reduce energy waste, improving system efficiency by up to 95%.

- Reliability: Press-pack housing ensures superior thermal cycling performance and short-circuit fault tolerance, with a mean time between failures (MTBF) exceeding 100,000 hours.

- Easy Integration: Simplified voltage balancing circuitry (RC snubbers + resistors) allows seamless series/parallel connections for scalable power systems.

- Compact Design: High power density (3 kA+ current handling in a compact form factor) saves space in industrial installations.

- Field-Proven: Deployed in over 1,000 MV drive systems globally, demonstrating stable operation in extreme conditions (e.g., -40°C to 85°C).

4. Application Areas and Case Studies

Industries:

- Industrial automation (motor drives, inverters)

- Power generation (wind/solar energy conversion)

- Power transmission (HVDC, SVCs)

- Heavy industries (metallurgy, mining).

Case Study:

A 10 MW MV drive system in a steel plant used the 5SHX1960L0004 for a 4.16 kV induction motor. The module’s fast switching (10 μs turn-off time) and low losses reduced harmonic distortion by 30%, improving power quality and extending motor lifespan.

A 10 MW MV drive system in a steel plant used the 5SHX1960L0004 for a 4.16 kV induction motor. The module’s fast switching (10 μs turn-off time) and low losses reduced harmonic distortion by 30%, improving power quality and extending motor lifespan.

5. Competitor Comparison

Compared to traditional IGBT modules in similar voltage/current ranges, the 5SHX1960L0004 offers:

- 20% lower switching losses (critical for high-power applications).

- Higher short-circuit tolerance (3× rated current for 10 ms).

- Simplified cooling requirements (reducing system complexity and costs).

- Better voltage balancing in series configurations (no active gate control needed).

5SHX1960L0004

6. Selection Recommendations

- Voltage/Current Matching: Ensure the module’s 4.5 kV/1960 A rating aligns with your system’s peak requirements.

- Cooling Strategy: Choose air/water-cooled variants based on ambient temperature and space constraints.

- Redundancy: For critical systems, use 1+1 redundancy (as demonstrated in HVDC projects).

- Compatibility: Verify interface standards (e.g., gate drive compatibility with ABB’s generation A/B units).

7. Precautions

- Thermal Management: Ensure adequate heat dissipation (e.g., heatsinks or cooling systems) to maintain <85°C operating temperature.

- Drive Circuit Design: Use ABB-recommended gate units (e.g., 3BHL000390P0104) for optimal switching performance.

- Safety Compliance: Follow IEC 60747-5-1 standards for high-voltage installations.

- Maintenance: Inspect for mechanical stress (e.g., contact pressure in press-pack modules) every 2 years.