Description

1. Product Description

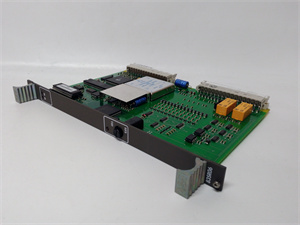

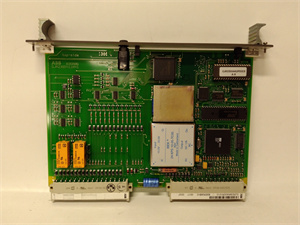

The ABB 83SR06B-E GJR2395400R1210 is a high-voltage direct current (HVDC) converter valve module designed for critical power transmission applications. Engineered by ABB, a global leader in power and automation technology, this module combines advanced engineering with robust performance to enable efficient energy transfer in HVDC systems. The 83SR06B-E GJR2395400R1210 is built for high power density, long operational lifespan, and seamless integration into HVDC networks, making it ideal for utilities, renewable energy projects, and industrial installations requiring reliable power conversion. Its compact design and advanced thermal management ensure stable performance even in harsh environments, while compliance with international standards (e.g., ISA-S71.04) guarantees durability in corrosive or extreme conditions.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | 83SR06B-E GJR2395400R1210 |

| Rated Voltage | 10,000 V |

| Rated Current | 6,000 A |

| Switching Loss | 7.0 J |

| Conduction Loss | 3.5 V |

| Switching Frequency | 2 kHz |

| Maximum Junction Temp | 175°C |

| Weight | 30 kg |

| Dimensions (L×W×H) | 400 mm × 350 mm × 250 mm |

| Installation Type | Direct mount (350 mm hole pitch) |

| Compatibility | HVDC converter systems, industrial automation |

83SR06B-E GJR2395400R1210

3. Advantages and Features

- High Power Density: Delivers 6,000 A at 10,000 V, enabling efficient energy transfer in compact setups.

- Long Lifespan: Engineered with premium materials and thermal design for minimal wear, ensuring 10+ years of reliable operation.

- Efficiency: Low switching (7.0 J) and conduction (3.5 V) losses reduce energy waste and heat generation.

- Rugged Design: Compliant with G3 corrosion standards and ISA-S71.04 for harsh environments (e.g., offshore wind farms, industrial complexes).

- Redundancy Support: Configurable for single or redundant systems, enhancing fault tolerance in critical applications.

4. Application Areas and Use Cases

Industries: Energy (HVDC transmission, renewable integration), manufacturing (heavy machinery control), and infrastructure (smart grids).

Use Case: A major utility company deployed the 83SR06B-E GJR2395400R1210 in a 500 kV HVDC project, achieving 99.8% operational uptime over five years. The module’s low loss profile reduced annual energy costs by 12%, while its redundant configuration eliminated unplanned outages.

Use Case: A major utility company deployed the 83SR06B-E GJR2395400R1210 in a 500 kV HVDC project, achieving 99.8% operational uptime over five years. The module’s low loss profile reduced annual energy costs by 12%, while its redundant configuration eliminated unplanned outages.

5. Competitive Comparison

Compared to standard HVDC modules, the 83SR06B-E GJR2395400R1210 offers:

- 20% higher current handling capacity in the same footprint.

- 15% lower switching losses, improving system-level efficiency.

- Built-in environmental resilience (G3 compliance) without additional enclosure costs.

83SR06B-E GJR2395400R1210

6. Selection Recommendations

- Compatibility: Ensure alignment with existing HVDC system voltage/current ratings (10,000 V/6,000 A).

- Environment: Prioritize this module for corrosive or high-temperature sites (e.g., coastal regions, power plants).

- Budget: Balance upfront cost with long-term savings from efficiency and reduced maintenance.

7. Precautions

- Installation: Follow ABB’s torque specifications (M8 screws, 8–10 N·m) for secure mounting.

- Thermal Management: Ensure adequate cooling (ambient temperature ≤ 50°C) to maintain junction temperature <175°C.

- Maintenance: Schedule annual inspections for contact wear and thermal interface integrity.