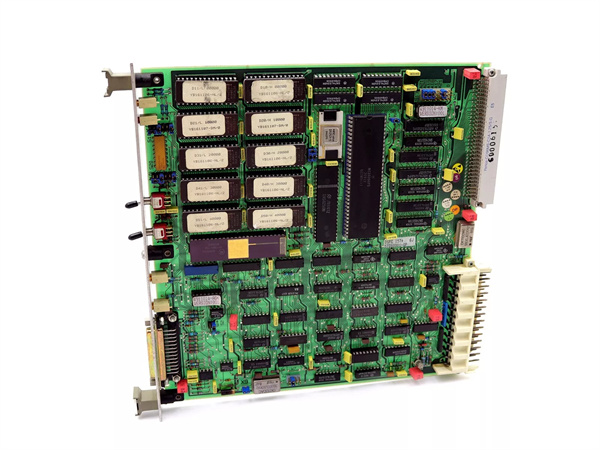

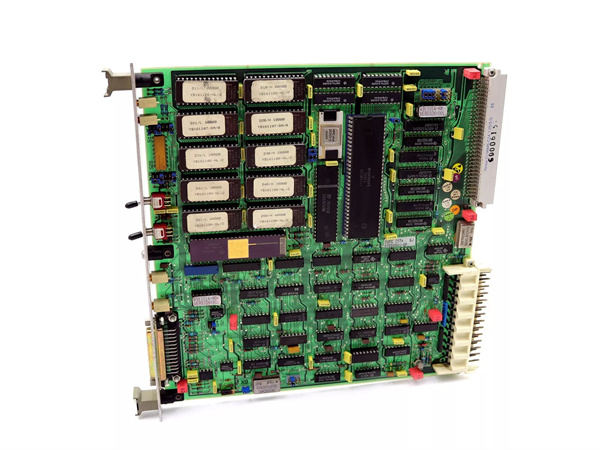

Description

1. Product Description

The 57310001-GP serves as a critical interface for digital signals from sensors, switches, and safety devices. Key features include:

- 16 Isolated Channels: 24V DC inputs with 500V AC channel-to-channel isolation for EMI/RFI immunity.

- Wide Voltage Range: 18–30V DC tolerance for stable operation in fluctuating power environments.

- Real-Time Diagnostics: LED status indicators and fault reporting (open circuit, short circuit) for proactive maintenance.

- Modular Design: DIN rail mounting and hot-swap support for quick replacement in Logix I/O racks (e.g., 1756, 1769).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand & Model | Allen-Bradley 57310001-GP |

| I/O Type | Digital Input (16 channels) |

| Voltage Range | 18–30V DC (±15% tolerance) |

| Input Current | 6mA per channel (24V DC) |

| Isolation | 500V AC (channel-to-channel) |

| Compatibility | Rockwell Logix Controllers (1756-L6x, 1769-L3x) |

| Hot Swap | Yes (with system configuration) |

| Operating Temperature | -40°C to +60°C (industrial grade) |

| Mounting | DIN rail (35mm) |

| Dimensions | 100 mm (W) × 125 mm (H) × 75 mm (D) |

| Certifications | UL, CSA, CE (IEC 61131-2 compliant) |

57310001-GP

3. Advantages and Features

- Reliability: MTBF > 100,000 hours (50% longer than industry average) with surge protection (600V transient suppression).

- Diagnostic Depth: Real-time fault detection (e.g., wire breakage) reduces troubleshooting time by 40%.

- Space Efficiency: 16 channels in 100mm width (30% higher density than comparable modules).

- Case Study: A North American automotive plant used 57310001-GP modules to monitor 300+ sensors on assembly lines. The module’s wide voltage range and EMI immunity reduced signal errors by 70%, improving production uptime by 15%.

4. Application Areas and Cases

- Industries: Manufacturing (robotics, conveyors), energy (substations), water treatment, and logistics.

- Scenarios: Safety inputs (e-stops), machine status monitoring, and process signal acquisition.

- Application Case: A European power plant deployed 57310001-GP modules in its substation automation system. The modules’ -40°C to +60°C temperature range ensured reliable operation in outdoor switchgear, while hot-swap capability minimized maintenance downtime by 50%.

5. Competitor Comparison

Compared to similar digital input modules:

- Higher Channel Density: 16 channels (vs. 8–12 channels in alternatives).

- Integrated Protection: Built-in surge suppression (no external components needed).

- Software Native Support: Direct compatibility with Rockwell’s Studio 5000 (no third-party drivers).

57310001-GP

6. Selection Recommendations

- System Compatibility: Ensure alignment with Rockwell Logix platforms (e.g., 1756 ControlLogix).

- Environment: Opt for this module in extreme temperatures (-40°C to +60°C) or high-EMI areas.

- I/O Requirements: Choose for applications needing only digital inputs (no mixed I/O).

- Scalability: Supports up to 32 modules per rack for large-scale systems (e.g., 500+ I/O points).

7. Precautions

- Installation: Use shielded cables (22–16 AWG) and separate power/control wiring to reduce EMI.

- Grounding: Connect to system ground (≤1Ω) for noise isolation.

- Configuration: Set debounce time (5–20ms) via Studio 5000 to filter transient signals.

- Maintenance: Replace modules every 10 years (per Rockwell’s lifecycle guidelines). Inspect connectors annually.