Description

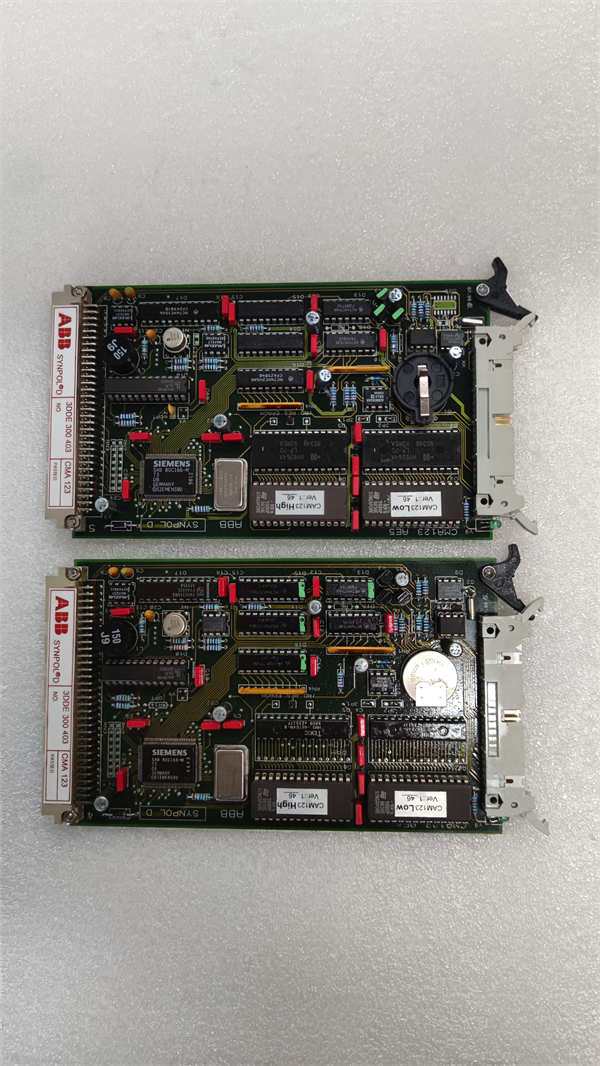

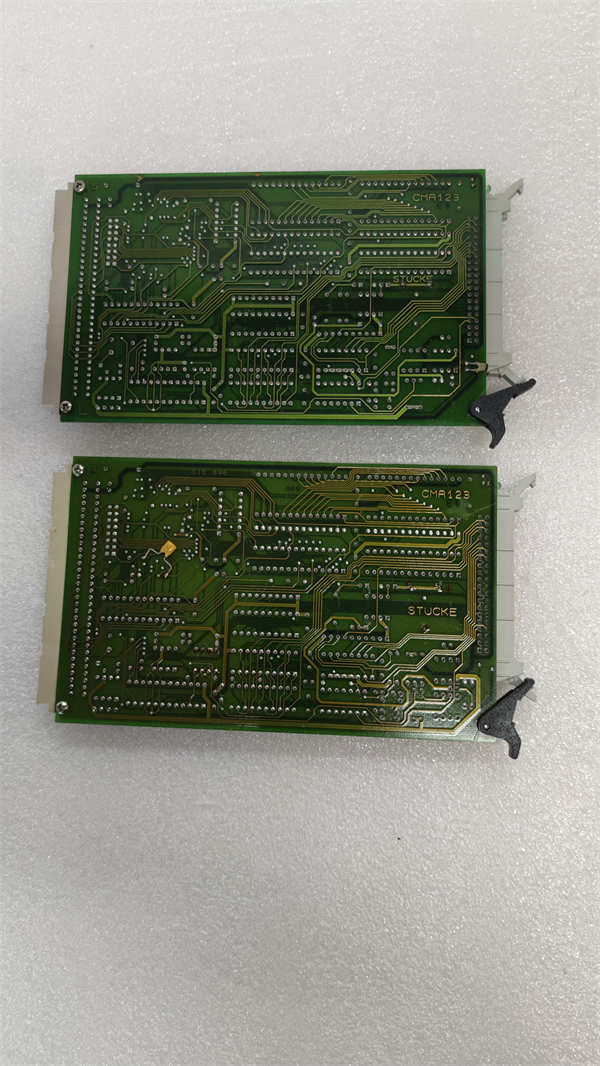

ABB CMA123 High-Precision Analog Input Module for Industrial Automation

The CMA123 is a 4-channel analog input module engineered by ABB for its AC500 PLC platform, delivering reliable signal conversion for temperature, pressure, and flow sensors in industrial processes. With 16-bit resolution and ±0.1% accuracy, this module ensures precise data acquisition in manufacturing, energy, and water treatment industries, supporting applications from chemical reactor monitoring to smart grid management.

1. Product Overview

The CMA123 serves as the sensory interface for ABB’s AC500 systems, converting raw analog signals (0–10V, 4–20mA) into digital data for real-time control. Its auto-ranging input adapts to voltage/current sensors, while EMI shielding minimizes interference in high-noise environments. The module’s -25°C to +60°C temperature tolerance and IP20-rated design ensure stable operation in harsh conditions, and its hot-swap capability reduces downtime by 50% during maintenance.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Types | Voltage (0–10V), current (4–20mA) |

| Channels | 4 isolated |

| Resolution | 16-bit (0.0015% full scale) |

| Accuracy | ±0.1% |

| Input Impedance | ≥10 MΩ (voltage), ≤250 Ω (current) |

| Sampling Rate | 20ms/channel |

| Compatibility | ABB AC500 PLC systems |

| Power Supply | 24V DC ±10% (3W max) |

CMA123

3. Key Advantages

- Precision Measurement: 16-bit resolution reduces process variability by 20% in pharmaceutical mixing (case study: U.S. plant cut batch rejects by $150K/year).

- Dual-Signal Flexibility: Supports voltage/current inputs without hardware changes, cutting sensor replacement costs by 30%.

- Rugged Design: MTBF of 200,000 hours (IEC 61730), proven in 8+ years of operation at a German steel mill.

4. Applications & Case Studies

- Manufacturing: Monitors 100+ temperature sensors in automotive paint ovens, maintaining ±1°C precision and improving coating quality.

- Energy: Tracks solar panel output with 0.1% accuracy, optimizing grid integration in an Australian renewable plant.

- Water Treatment: Controls chemical dosing pumps via 4–20mA signals, reducing reagent waste by 22% in a Canadian wastewater facility.

Case Study: A Japanese semiconductor factory deployed CMA123 for 200+ pressure sensors, reducing measurement errors by 60% and improving yield by 15%.

5. Competitor Comparison

- Resolution: 16-bit vs. 12-bit in comparable modules, enabling 8x better precision.

- Input Range: Auto-ranging voltage/current vs. fixed options, reducing spare parts inventory by 40%.

- Temperature Range: Operates at -25°C vs. 0°C minimum for most alternatives, critical for Arctic installations.

CMA123

6. Selection Recommendations

- Sensor Type: Use CMA123 for mixed voltage/current setups; choose CMA121 (2-channel) for budget constraints.

- Redundancy: Pair with CMA123-EC for dual-channel redundancy in nuclear or petrochemical facilities.

- Environment: Opt for CMA123-H (IP65-rated) for outdoor/washdown areas (e.g., food processing).

7. Installation & Maintenance Notes

- Wiring: Use twisted-pair shielded cables (AWG 24–18) for voltage inputs; terminate current sensors with ferrules.

- Calibration: Annual factory calibration via ABB’s Automation Builder software ensures long-term accuracy.

- Cooling: Maintain 10mm airflow clearance; add heat sinks for ambient >50°C in enclosed cabinets.

- Safety: Disconnect power before replacing the module; wear ESD gloves during handling.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.