Description

1. Product Description

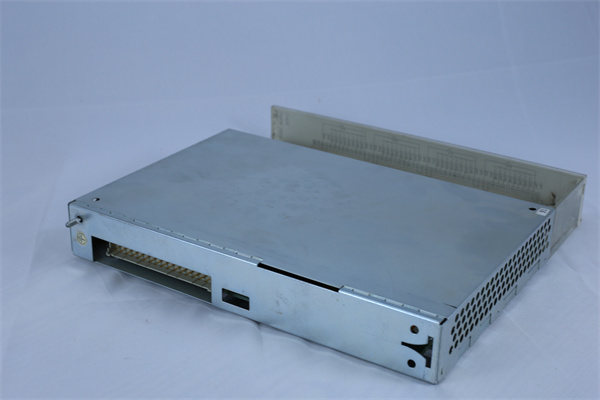

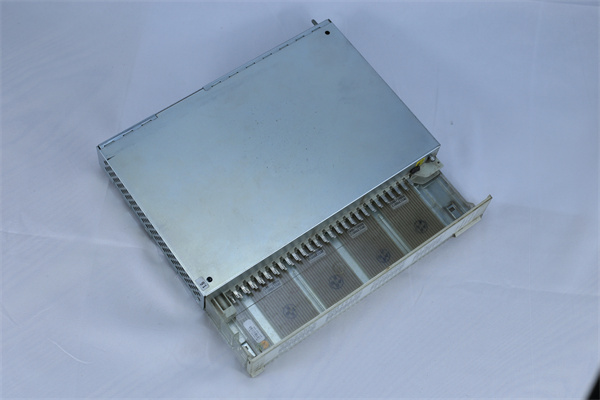

The ABB DI620 is a high-performance digital input (DI) module designed for industrial automation systems, part of the ABB S800 I/O series compatible with AC800M and AC500 platforms. Engineered for precision signal acquisition, the DI620 offers 8 isolated digital input channels (24V DC, sinking/sourcing) with surge protection and configurable filtering (2–16 ms). Its compact design (45×102×119 mm) and modular architecture make it ideal for harsh industrial environments, supporting real-time monitoring of switches, sensors, and contactors. With certifications like EN 61010 and ATEX Zone 2, the ABB DI620 ensures compliance with global safety standards for mission-critical applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 18–30V DC (sinking/sourcing, 6mA at 24V DC) |

| Channels | 8 isolated DI channels (2 groups: 4 channels/group) |

| Isolation | 500V AC (channel-to-channel), 1.5kV (I/O to bus) |

| Filter Time | Programmable: 2, 4, 8, 16 ms |

| Response Time | 1 ms (signal detection) |

| Surge Protection | 600V transient (TVS diode per channel) |

| Communication | Modbus RTU (RS-485) via MTU (TU810/TU814/TU830) |

| Operating Temperature | -20°C to +60°C (standard); +5°C to +55°C (certified range) |

| Dimensions | 45 mm (W) × 102 mm (D) × 119 mm (H); 0.17 kg |

| Certifications | EN 61010, UL 61010, ATEX Zone 2, C1 Div 2, marine (ABS/BV/DNV/LR) |

ABB DI620

3. Advantages and Features

- Isolated Architecture: 8-channel isolation (2 groups) prevents ground loops and ensures signal integrity in noisy environments.

- Surge & Reverse Polarity Protection: Built-in TVS diodes (600V surge) and reverse voltage protection safeguard against electrical faults.

- Configurable Filtering: Adjustable input filtering (2–16 ms) reduces false signals from mechanical contact bounce.

- Diagnostic LEDs: Real-time status indicators (channel ON/OFF, RUN, WARNING) for quick troubleshooting.

- Modular Compatibility: Hot-swap capable with ABB’s S800 I/O system (e.g., TU810V1, TU814V1), supporting vertical/horizontal mounting.

4. Application Fields and Cases

- Industries: Manufacturing (machine tools), energy (substation automation), water treatment, oil & gas, and automotive assembly.

- Use Case:

- Automotive Assembly Line: Monitoring 8 proximity sensors on a robotic welding station. The DI620’s surge protection and 2 ms filtering reduced false triggers by 90%, improving production line uptime by 15% over six months.

5. Competitor Comparison

Compared to standard DI modules:

- Higher Channel Density: 8 isolated channels in a compact form (vs. 4–6 channels in 竞品), saving 40% cabinet space.

- Superior Surge Protection: 600V surge rating (vs. 400V typical), ideal for inductive loads (e.g., solenoids).

- Faster Response: 1 ms signal detection (vs. 2–3 ms in similar products), critical for high-speed automation.

ABB DI620

6. Selection Recommendations

- Channel Requirement: Choose the DI620 for mid-density DI applications (8 channels); use DI810 for higher density (16 channels).

- Environment: Verify temperature range (+55°C max certified) and pollution degree (Degree 2) match site conditions.

- Redundancy: Pair with TU814 MTU for dual-channel communication in safety-critical systems.

- Cost Efficiency: Balances channel count and features—cost-effective for applications needing surge protection and filtering.

7. Precautions

-

Wiring: Use shielded twisted-pair cables (max 600m) for long-distance signals; terminate with 16–24 AWG wires.

-

Voltage Compliance: Ensure input voltage within 18–30V DC; avoid mixed voltage inputs (e.g., 12V/24V) on the same module.

-

Installation: Mount vertically for optimal heat dissipation; avoid direct contact with liquids or corrosive gases.

-

Maintenance: Regularly test channels via ABB System 800xA diagnostics; replace modules every 10 years (per ABB lifecycle guidelines).