Description

1. Product Description

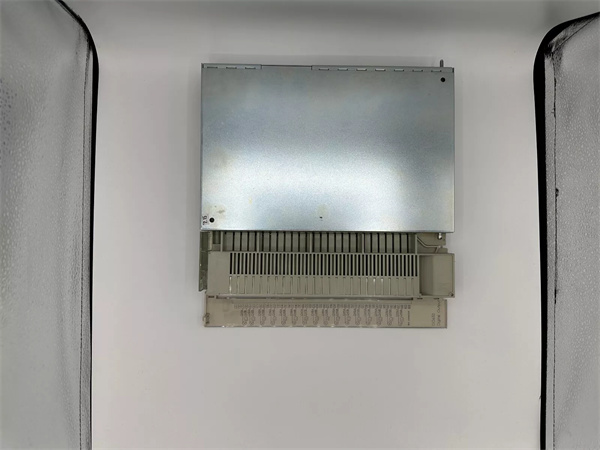

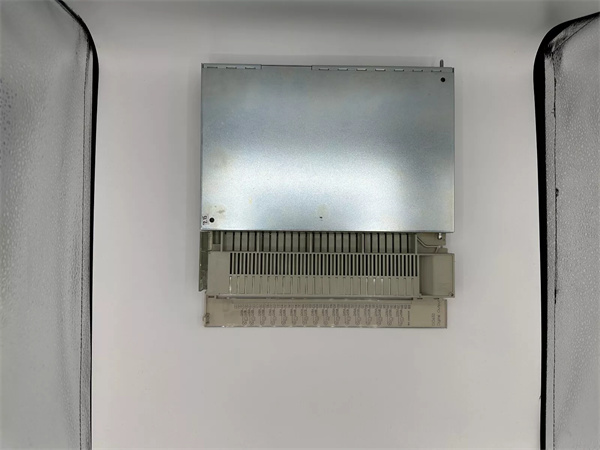

The ABB DO630 serves as a digital output hub for industrial networks, enabling precise control of up to 16 independent loads. Each channel features galvanic isolation (2.5 kV) to prevent signal interference, while relay contacts (SPST-NO) support direct switching of inductive or resistive loads. Compatible with Advant Controller 110/160 and Advant OCS systems, the module operates on 24 VDC power and offers a compact form factor (252 mm × 273 mm × 40 mm) for space-constrained cabinets. Its rugged design (IP20 protection) ensures performance in harsh environments (temperature: -20°C to +55°C), making it suitable for manufacturing, energy, and water treatment applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | DO630 (Part No.: 3BHT300007R1) |

| Brand | ABB |

| Channels | 16 (isolated, SPST-NO relay contacts) |

| Voltage Rating | 250 VAC (load), 24 VDC (supply) |

| Switching Current | 2 A per channel (resistive), 1 A (inductive) |

| Isolation | 2.5 kV (channel-to-channel, channel-to-ground) |

| Dimensions | 252 mm × 273 mm × 40 mm |

| Weight | 1.32 kg |

| Operating Temperature | -20°C to +55°C |

| Protection Class | IP20 |

| Certifications | CE, RoHS (2011/65/EU) |

ABB DO630

3. Advantages and Features

- Isolated Multi-Channel Control: 16 galvanically isolated channels minimize cross-interference, enhancing system stability in complex setups.

- High-Voltage Compatibility: Supports 250 VAC loads, eliminating the need for intermediate relays in high-power applications.

- Reliable Relay Technology: SPST-NO contacts with 100,000+ mechanical life cycles ensure long-term durability for frequent switching.

- Compact Design: Space-saving layout (40 mm width) optimizes panel space in modular control systems.

- Easy Integration: Plug-and-play compatibility with ABB’s Advant OCS platforms reduces commissioning time (<1 hour).

4. Application Fields and Cases

Industries: Manufacturing (automotive, food & beverage), energy (power plants), water treatment, and building automation.

Scenarios: Valve control, motor starters, lighting systems, and conveyor actuators.

Scenarios: Valve control, motor starters, lighting systems, and conveyor actuators.

Case Study: A water treatment plant deployed the DO630 to manage 16 solenoid valves in a filtration system. Its 250 VAC switching and channel isolation reduced equipment failures by 30%, while the compact design saved 20% panel space. The module’s relay contacts handled frequent on/off cycles (500+ daily operations) with zero downtime over 2 years.

5. Competitor Comparison

Compared to similar modules (e.g., 8–12 channel alternatives), the DO630 offers 33% more channels in a comparable footprint. Its 250 VAC rating surpasses typical 24 VDC-only modules, reducing external component costs by 15% (no voltage conversion needed). Relay contacts provide superior load handling (2 A vs. 0.5 A solid-state outputs in some 竞品), making it ideal for heavy-duty applications.

ABB DO630

6. Selection Recommendations

- Channel Requirements: Choose DO630 for systems needing 16+ isolated outputs; opt for smaller modules (e.g., DO620) for fewer channels.

- Voltage Needs: Ensure 250 VAC load compatibility; use DC modules (e.g., DO632) for low-voltage applications.

- Environment: Verify temperature (-20°C to +55°C) and IP20 protection match site conditions.

- Cost vs. Performance: New units ($2.5k–$3k) offer 1-year warranty; refurbished options ($1.8k–$2.2k) with 6-month warranty suit budget constraints.

7. Precautions

- Installation: Follow ABB’s wiring guidelines; torque screws to 0.5–0.8 N·m to avoid contact damage.

- Load Management: Do not exceed 2 A per channel (resistive) or 1 A (inductive); use surge protection for inductive loads.

- Safety: Disconnect power before servicing; ensure compliance with local electrical codes (e.g., NEC, IEC).

- Maintenance: Replace relays every 100,000 cycles or 5 years (whichever comes first); monitor LED indicators (green: power; red: fault).