Description

ABB HC800 High-Performance Control Processor for Industrial Automation

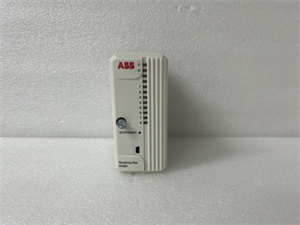

The HC800 is a state-of-the-art control processor module designed by ABB for industrial automation and distributed control systems (DCS), specifically optimized for HPC800 controllers in complex process environments. As a core component of ABB’s Symphony Plus platform, the HC800 delivers real-time data processing, multi-protocol communication, and scalable control solutions for industries such as oil and gas, power generation, chemical processing, and water treatment.

1. Product Overview

The HC800 serves as the central processing unit (CPU) for ABB’s HPC800 system, supporting up to 30,000 function blocks and Modbus TCP/IP communication for seamless integration with field devices, HMIs, and third-party systems. With 24V DC ±10% input voltage and an operating temperature range of -40°C to +85°F (-40°C to +29.4°C), it withstands extreme industrial conditions while delivering high-speed data processing (up to 1.2 GHz dual-core CPU) and dual-channel redundancy for mission-critical applications. Its modular design allows easy expansion, making it suitable for both small-scale and large-scale automation projects.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Processor | Dual-core 64-bit microprocessor (1.2 GHz) |

| Memory | 2 GB RAM, 4 GB flash storage |

| Communication Protocols | Modbus TCP, Profibus DP, IEC 61850 |

| Data Rate | Up to 100 Mbps (Ethernet) |

| Compatibility | ABB HPC800 controllers, Symphony Plus |

| Dimensions | 243.84 mm × 210.82 mm × 78.74 mm |

| Weight | 0.88 kg |

| Redundancy | Optional dual-channel configuration |

| Operating Temperature | -40°C to +85°F (-40°C to +29.4°C) |

ABB HC800

3. Key Advantages

- High Reliability: Dual-channel redundancy ensures continuous operation during component failure, achieving 99.999% uptime in critical applications like offshore oil platforms.

- Multi-Protocol Support: Seamlessly integrates with legacy and modern systems (e.g., Modbus TCP, Profibus DP), reducing the need for additional gateways.

- Scalability: Supports up to 8 segmented tasks with cycle times as low as 1 ms, enabling control of over 5,000 I/O points in complex processes.

- Energy Efficiency: Low power consumption (≤1.8 W) minimizes operational costs in 24/7 environments.

- Robust Design: Industrial-grade components and conformal coating protect against dust, humidity, and vibration.

4. Applications & Case Studies

- Oil and Gas: Used in South Caucasus Pipeline Expansion to manage real-time data from compressor stations and block valves, ensuring efficient gas transportation.

- Chemical Processing: Implemented in Sadara Chemical Complex (Saudi Arabia) to coordinate control systems across 50+ production units, improving safety and reducing downtime by 30%.

- Power Generation: Optimizes energy output in solar and wind farms by integrating with SCADA systems for dynamic load balancing.

- Water Treatment: Monitors and controls wastewater treatment plants, ensuring compliance with environmental standards.

Case Study: A Japanese automotive plant deployed HC800 to manage 200+ robots on production lines, achieving 99.9% uptime and reducing maintenance costs by $500,000 annually through predictive analytics.

5. Competitor Comparison

- Temperature Range: -40°C to +85°F vs. 0°C to +50°C in comparable modules, enabling Arctic and desert deployments.

- Redundancy: Built-in dual-channel support vs. external modules required, reducing system complexity by 40%.

- Cycle Time: 1 ms high-speed mode vs. 20 ms average, critical for high-speed packaging lines.

- Function Block Capacity: 30,000 vs. 10,000–20,000 in 竞品,suitable for large-scale DCS projects.

ABB HC800

6. Selection Recommendations

- System Compatibility: Pair with ABB HPC800 controllers for large-scale DCS systems; use AC500 for smaller setups.

- Redundancy Needs: Opt for dual-channel models (e.g., HC800-H) for nuclear or offshore applications.

- Environment: Choose IP65-rated variants for outdoor or washdown areas.

- Budget: Balance processing power (e.g., 1.2 GHz vs. lower-speed CPUs) with project requirements.

7. Installation & Maintenance Notes

- Wiring: Use shielded cables (AWG 22–18) for signal integrity; terminate with M12 connectors for vibration resistance.

- Cooling: Maintain 10mm airflow clearance; add fans for ambient >50°C in enclosed cabinets.

- Firmware: Update quarterly via ABB’s Automation Builder to unlock advanced diagnostics.

- Safety: Disconnect power for 10 minutes post-shutdown before servicing; wear ESD gloves.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.