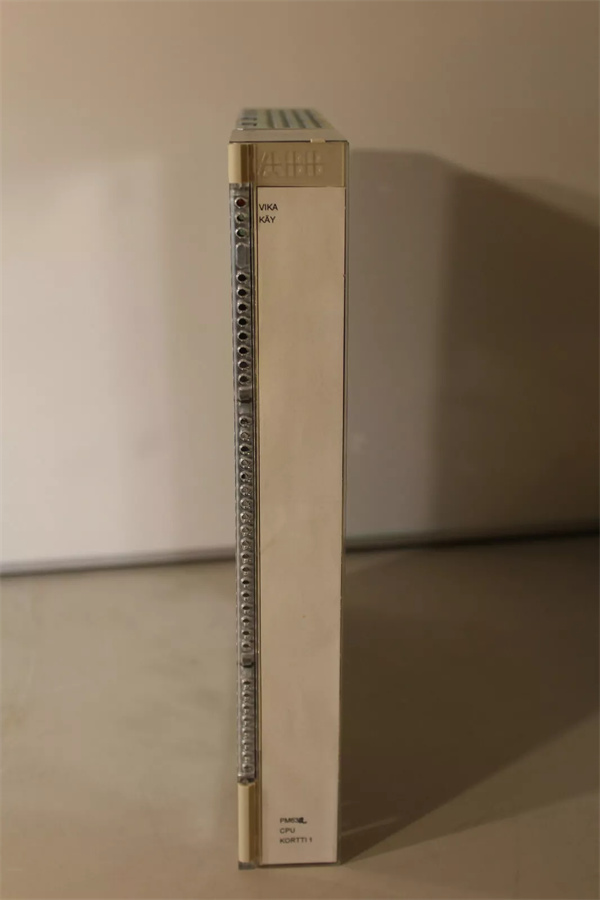

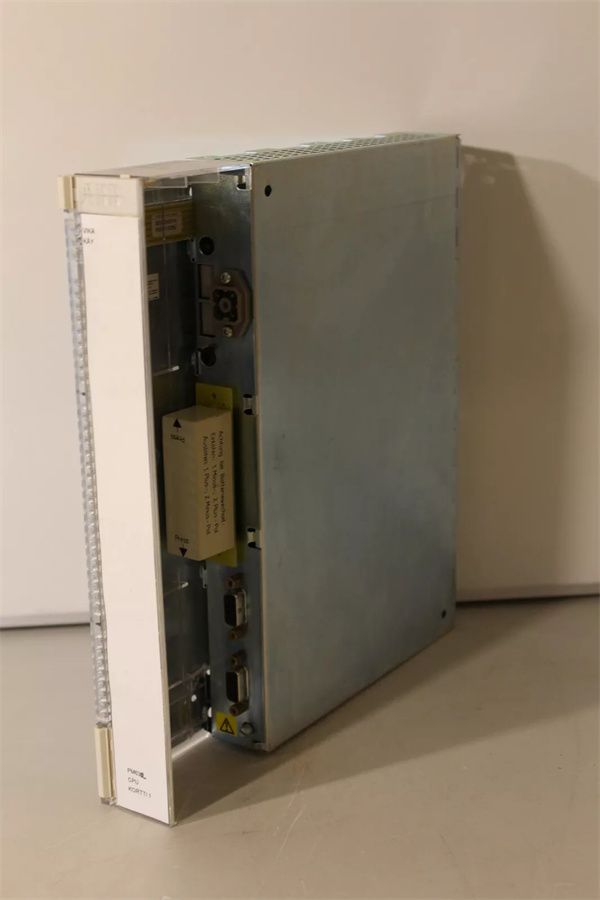

Description

1. Product Description

The ABB PM632 is a compact yet powerful PLC built for reliability and efficiency. It supports multiple programming languages (IEC 61131-3) and offers scalable I/O configurations, enabling tailored solutions for industries such as manufacturing, energy, and water treatment. Key features include redundant power supply support, built-in safety functions, and rugged design for harsh environments. The PM632 simplifies system expansion and reduces downtime, making it a cost-effective choice for critical operations.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 V DC (18–30 V DC) |

| Current | 0.8 A (max at 24 V DC) |

| Processor | 32-bit ARM Cortex-R4 (400 MHz) |

| Memory | 256 MB RAM, 512 MB flash (user-programmable) |

| Communication Interfaces | Ethernet/IP, Modbus RTU/TCP, PROFIBUS DP |

| I/O Compatibility | ABB AC500, AC500-eCo modules |

| Operating Temperature | -20°C to +60°C |

| Certifications | CE, UL, RoHS |

ABB PM632

3. Advantages and Features

- High Reliability: MTBF > 100,000 hours (per ABB testing), ensuring continuous operation in demanding conditions.

- Energy Efficiency: Low power consumption (≤20 W) with sleep mode for idle periods.

- Flexible Integration: Supports up to 1,024 I/O points via distributed modules (e.g., ABB PM5xx series).

- Security: Built-in cybersecurity features (data encryption, secure boot).

- Remote Monitoring: Web-based interface for real-time diagnostics and firmware updates.

4. Application Areas and Cases

Industries: Manufacturing (assembly lines), energy (power plants), water/wastewater treatment, oil & gas.

Case Study: A chemical plant in Germany reduced downtime by 35% using the PM632 for predictive maintenance. Its redundant communication links and fault-tolerant design minimized system failures during 24/7 operations.

Case Study: A chemical plant in Germany reduced downtime by 35% using the PM632 for predictive maintenance. Its redundant communication links and fault-tolerant design minimized system failures during 24/7 operations.

5. Competitor Comparison

Compared to similar mid-range PLCs, the PM632 offers:

- 20% faster cycle time (1 ms for 10k instructions).

- Native support for OPC UA (no add-on modules required).

- Lower total cost of ownership (5-year warranty vs. industry-standard 3 years).

ABB PM632

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing ABB systems (e.g., AC500 platform).

- Environment: Choose IP65-rated enclosures for outdoor/harsh environments.

- Scalability: Opt for PM632 variants with integrated Ethernet for future IoT upgrades.

- Budget: Balance I/O capacity (base model: 32 DI/DO; expandable to 1k+ points) with project needs.

7. Precautions

-

Installation: Follow ABB’s torque guidelines (4–6 N·m for DIN rail mounting).

-

Maintenance: Replace internal battery every 5 years (model: CR123A).

-

Safety: Use surge protection (2.5 kV) for power inputs in lightning-prone regions.

-

Software: Always update firmware via ABB’s DigiMatic Tool (compatible with Windows 10/11).