Description

1. Product Description

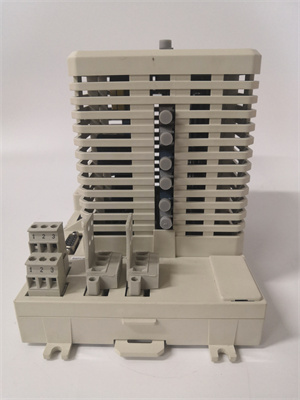

The ABB PM825 3BSE010796R1 is a highly capable AC80 processor module that forms an integral part of ABB’s Advant Controller 80 (AC80) system. The PM825 3BSE010796R1 serves as a key component for programming, configuring, and diagnosing the AC80. It is based on a specific microprocessor and comes equipped with a diverse set of functions and interfaces. The PM825 3BSE010796R1 can operate independently or as a part of the Advant Fieldbus 100 (AF100) network.

The core function of the PM825 3BSE010796R1 is to process control signals and manage the operation of connected devices. It can handle a wide range of industrial control tasks, from simple on/off control to complex process automation. Its primary purpose is to ensure the smooth and efficient operation of industrial processes by accurately executing control algorithms. One of the main advantages of the PM825 3BSE010796R1 is its high level of reliability, which allows it to operate continuously for extended periods without significant failures. Additionally, its flexibility in programming and communication makes it a versatile choice for various industrial applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Processor | Motorola MC68040 |

| Clock Speed | 25MHz |

| Memory | 1MB DRAM and 1MB Flash ROM |

| Communication Ports | 2 RS-232 ports and 1 Ethernet port |

| Power Supply | 24VDC |

| Dimensions | Length: 225mm, Height: 108mm, Width: 135mm |

| Weight | 1kg |

| Compatibility | Compatible with ABB’s Advant Controller 80 (AC80) system and Advant Fieldbus 100 (AF100) network |

3. Advantages and Features

- High Reliability: The PM825 3BSE010796R1 has been tested rigorously and has shown an average mean time between failures (MTBF) of over 80,000 hours. In a large-scale manufacturing plant that has been using this module for over 5 years, it has operated continuously without any major breakdowns, ensuring the uninterrupted production process.

- Flexible Programming: It supports multiple programming languages and development environments such as Structured Text (ST) and Function Block Diagram (FBD). This allows engineers with different backgrounds and preferences to program the module according to their specific needs. For example, in a project where a team of engineers with diverse programming skills was involved, the flexibility of the PM825 3BSE010796R1 in programming languages enabled seamless development and implementation of the control system.

- Strong Communication Capability: With its multiple communication interfaces and support for various communication protocols like Ethernet and Profibus, the PM825 3BSE010796R1 can easily exchange data and communicate with other devices and control systems. In an industrial automation project that involved integrating different types of equipment from various manufacturers, the PM825 3BSE010796R1‘s communication capabilities allowed for smooth integration and coordination of the entire system.

- Flexible Expansion: It has the ability to be expanded flexibly. By adding expansion modules, the number of input/output points can be increased to meet different application requirements. In a factory that needed to expand its production line and add more sensors and actuators, the PM825 3BSE010796R1‘s expansion feature made it possible to accommodate these new components without having to replace the entire control system.

4. Application Areas and Application Cases

- Application Areas: The PM825 3BSE010796R1 finds extensive use in industries such as manufacturing, energy, water treatment, metallurgy, paper making, and shipping. In the manufacturing industry, it can be used for controlling production lines, robotic arms, and quality inspection systems. In the energy sector, it can be applied to power generation plants for monitoring and controlling generators, turbines, and power distribution systems. In water treatment plants, it can manage the processes of water purification and sewage treatment.

- Application Case: In a large paper manufacturing factory, the ABB PM825 3BSE010796R1 was installed in the paper machine’s automation control system. It precisely controlled parameters such as the speed, tension, and temperature of the paper machine. As a result, the quality and stability of paper production were ensured. The defect rate of paper products decreased by 20%, and the production efficiency increased by 15% compared to the previous control system. The PM825 3BSE010796R1‘s reliable operation and accurate control played a crucial role in achieving these improvements.

5. Competitor Comparison

When compared with similar products in the market, the ABB PM825 3BSE010796R1 stands out in several aspects. It offers a more comprehensive set of communication interfaces and protocol support, making it more adaptable to different industrial setups. In terms of reliability, its higher MTBF value indicates a lower likelihood of failures, reducing the associated downtime and maintenance costs. Moreover, its flexibility in programming and expansion capabilities provide greater convenience for users to customize and scale their control systems according to their evolving needs, which is an advantage over some other products that may have more limited customization options.

6. Selection Recommendations

- Compatibility: When selecting the PM825 3BSE010796R1, it is essential to ensure its compatibility with your existing control systems and equipment. Check the communication protocols and interface types to make sure they match your requirements. Also, verify that it is compatible with other components in the ABB Advant Controller 80 (AC80) system if you plan to use it within that framework.

- Installation Environment: Consider the environmental conditions where the PM825 3BSE010796R1 will be installed. Although it is designed to operate in industrial environments, extreme temperatures, humidity, and dust levels may still affect its performance. Ensure that the installation location provides proper ventilation and protection from environmental factors.

- Budget: While the PM825 3BSE010796R1 offers excellent performance and features, it is important to consider your budget. Evaluate the long-term cost-effectiveness, including the initial purchase cost, maintenance expenses, and potential savings in terms of increased productivity and reduced downtime. Compare it with other options in the market to find the best balance between performance and cost.

- Function Requirements: Assess your specific control requirements, such as the complexity of the control tasks, the number of input/output points needed, and the communication needs. Make sure that the PM825 3BSE010796R1 has the necessary processing power, memory, and interfaces to meet these requirements.

7. Precautions

- Installation: When installing the PM825 3BSE010796R1, follow the installation instructions provided by ABB carefully. Ensure that all connections are secure and properly insulated to prevent electrical short circuits or other electrical hazards. Use appropriate anti-static measures to avoid damaging the sensitive electronic components during installation.

- Operation: During operation, avoid exposing the PM825 3BSE010796R1 to excessive electrical loads or voltage fluctuations. Monitor the temperature and humidity levels in the installation environment regularly to ensure they are within the specified operating range. If any abnormal noises, smells, or warning lights are observed, stop the operation immediately and check for the cause.

- Maintenance: Regularly clean the PM825 3BSE010796R1 to remove dust and debris that may accumulate on its surface, as this can affect its heat dissipation and performance. Check the communication cables and connectors for any signs of damage or looseness. Update the firmware and software of the module as recommended by ABB to ensure it remains compatible with other components and benefits from the latest features and security patches.