Description

1. Product Description

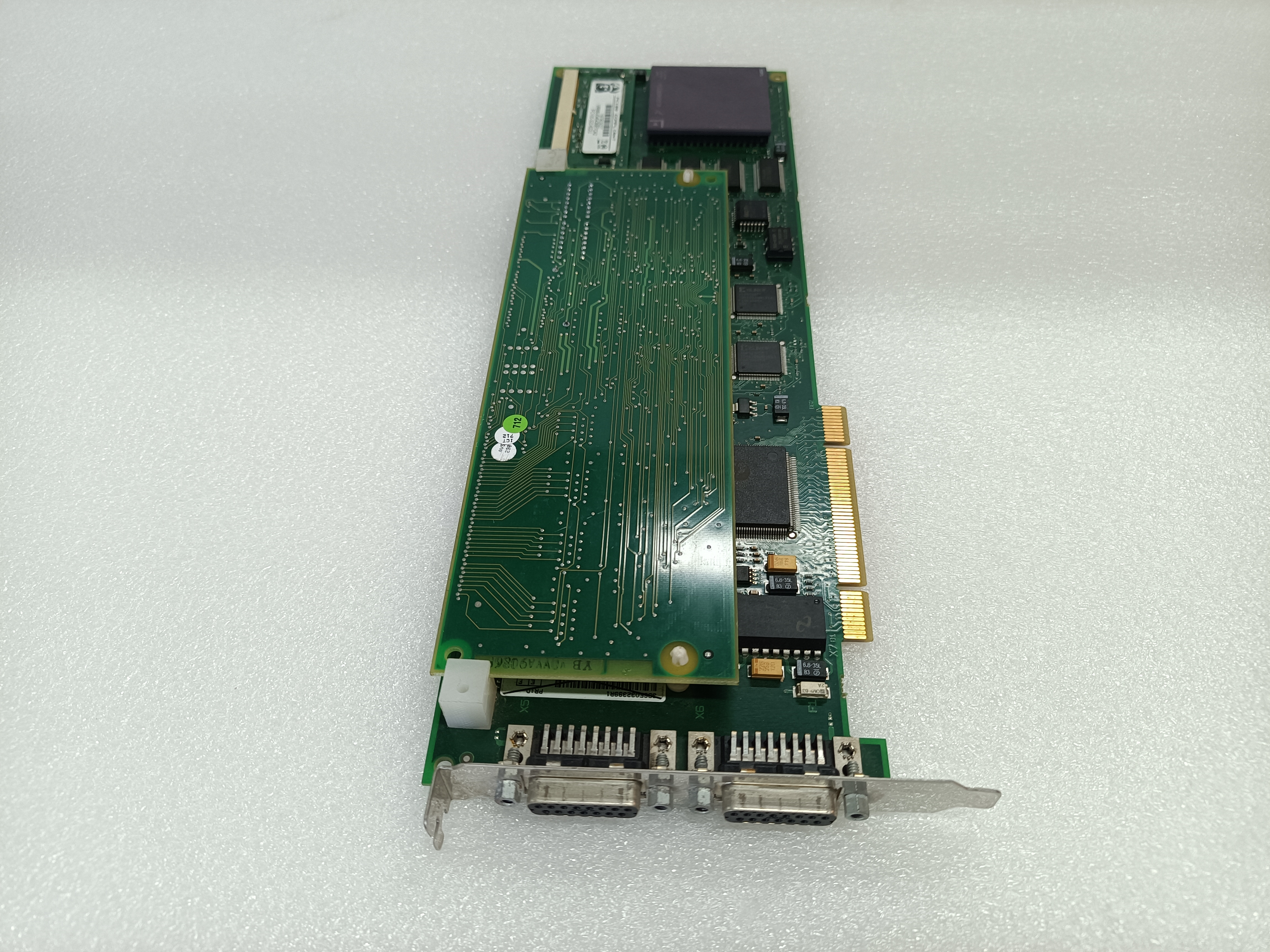

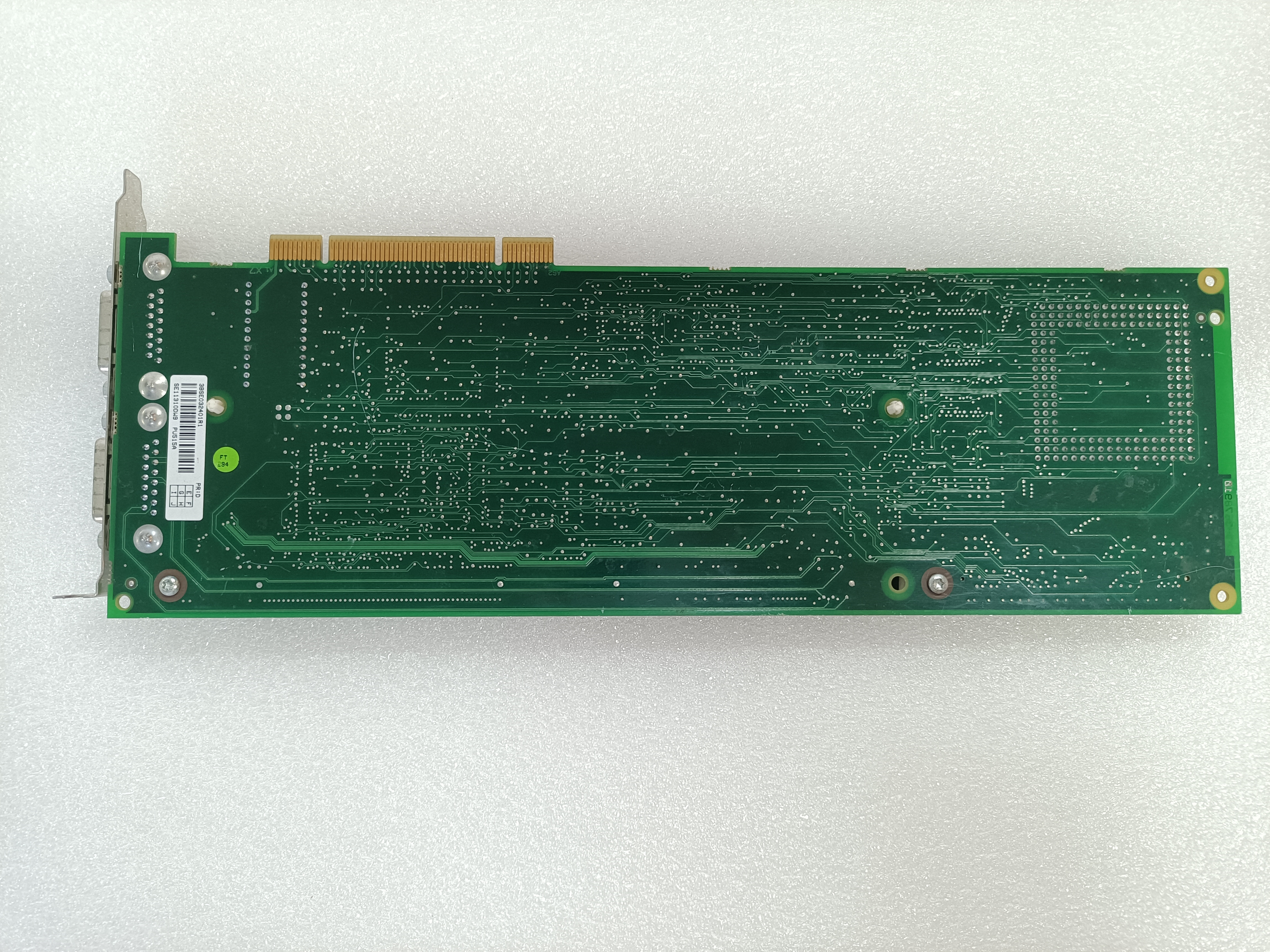

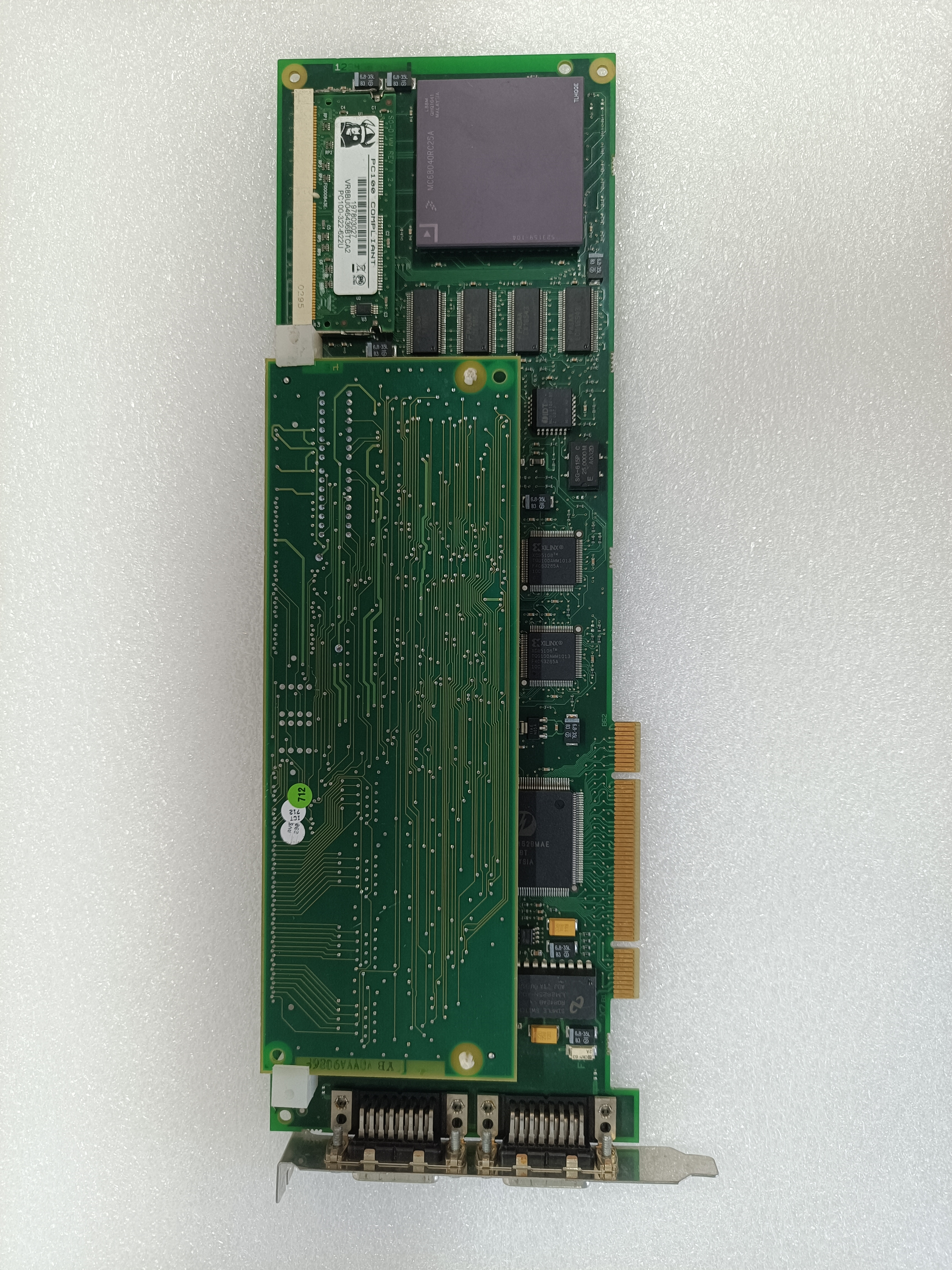

The ABB PU515A 3BSE032401R1 is a high-performance programmable logic controller (PLC) processor unit designed for industrial automation and control systems. As part of ABB’s advanced AC500 PLC series, the PU515A 3BSE032401R1 offers robust processing capabilities, flexible communication options, and seamless integration with industrial networks. Ideal for complex automation tasks, this module supports real-time data processing, remote monitoring, and efficient control of machinery and processes. Its compact design and rugged construction make it suitable for harsh industrial environments. The PU515A 3BSE032401R1 is widely used in manufacturing, energy, and infrastructure sectors, delivering reliable performance and scalability for diverse applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PU515A 3BSE032401R1 |

| Brand | ABB |

| Type | PLC Processor Unit |

| Voltage | 24 V DC (±10%) |

| Memory | 512 KB (user program), 256 KB (data) |

| Processing Speed | 0.15 ms/kB (IEC 61131-3 standard) |

| Communication Interfaces | Ethernet (TCP/IP), PROFIBUS DP, CANopen |

| Compatibility | ABB AC500 series (e.g., PM581, CM572) |

| Dimensions (W×H×D) | 110 × 160 × 110 mm |

| Weight | 0.8 kg |

PU515A 3BSE032401R1

3. Advantages and Features

- High Reliability: Built with industrial-grade components, the PU515A 3BSE032401R1 offers a mean time between failures (MTBF) of over 100,000 hours, ensuring continuous operation in critical systems.

- Flexible Integration: Supports multiple communication protocols (Ethernet, PROFIBUS, CANopen) for seamless integration with sensors, actuators, and SCADA systems.

- Energy Efficiency: Low-power design (≤5 W standby) reduces operational costs.

- Easy Maintenance: Hot-swap capability and intuitive diagnostics simplify troubleshooting and replacement.

- Scalability: Expandable via ABB’s modular I/O system (e.g., DI521, DO522) for customized control solutions.

4. Application Areas and Use Cases

Industries: Manufacturing, energy (oil/gas, power plants), water treatment, and automotive.

Scenarios: Machine control, process automation, conveyor systems, and building automation.

Scenarios: Machine control, process automation, conveyor systems, and building automation.

Case Study: A food processing plant in Germany upgraded its packaging line with the PU515A 3BSE032401R1. The PLC’s real-time processing and PROFIBUS integration reduced downtime by 20% and improved throughput by 15%, resulting in annual cost savings of €120,000.

5. Competitor Comparison

Compared to similar PLC processors, the PU515A 3BSE032401R1 offers:

- Faster processing speed (0.15 ms/kB vs. industry average 0.2–0.3 ms/kB).

- Higher memory capacity (512 KB program memory vs. typical 256–384 KB).

- Built-in cybersecurity features (e.g., IPsec encryption) for enhanced network protection.

- Lower power consumption (5 W vs. 7–10 W for 竞品 models).

PU515A 3BSE032401R1

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing ABB AC500 modules (e.g., power supply PM581).

- Environment: Verify temperature (-25°C to +60°C) and humidity (5–95% non-condensing) requirements match the installation site.

- Performance Needs: Choose the PU515A for mid-sized systems (up to 1,000 I/O points); opt for higher models (e.g., PU520) for larger applications.

- Budget: Balance cost with features—PU515A offers premium performance at a competitive price point.

7. Precautions

- Installation: Follow ABB’s mounting guidelines (DIN rail or panel mounting) and ensure proper grounding.

- Safety: Disconnect power before replacing modules to avoid electric shock.

- Software: Use ABB’s Automation Builder software (Version 4.0+) for programming and updates.

- ESD Protection: Handle the module with anti-static equipment to prevent damage.

- Maintenance: Schedule annual checks for dust accumulation and firmware updates.