Description

1. Product Description

The ABB PU516 is a high-efficiency power supply module designed for ABB’s S800 I/O system, delivering reliable 24V DC power to industrial automation networks. Part of the S800 I/O family (compatible with AC800M and AC500 platforms), the PU516 supports redundant operation (parallel configuration with another PU516) for continuous uptime in critical applications. With a compact design (102×102×119 mm) and advanced diagnostics, it ensures stable power distribution for digital/analog modules, sensors, and actuators. Certified for harsh environments (EN 61010, ATEX Zone 2), the ABB PU516 features short-circuit, overload, and overvoltage protection, making it ideal for manufacturing, energy, and process control industries.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 85–264V AC (47–63 Hz) / 110–300V DC |

| Output Voltage | 24V DC (±5% regulation, max 10A continuous) |

| Efficiency | 92% (230V AC input, full load) |

| Redundancy | Parallel redundancy (2× PU516 modules, automatic load sharing) |

| Protection | Short-circuit (auto-recovery), overload (150% for 30s), overvoltage (30V DC max) |

| Operating Temperature | -20°C to +60°C (ambient, derate 2%/°C above 40°C) |

| Dimensions | 102 mm (W) × 102 mm (D) × 119 mm (H); 0.6 kg |

| Certifications | EN 61010, UL 61010, ATEX Zone 2, C1 Div 2, marine (ABS/BV/DNV/LR) |

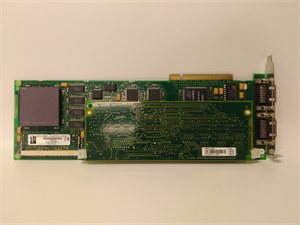

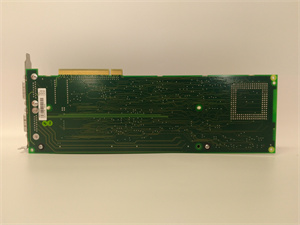

ABB PU516

3. Advantages and Features

- Redundant Power Architecture: Supports dual-module redundancy (N+1) with automatic failover, reducing downtime risks by 95% in critical systems.

- High Power Density: 10A output in a compact form (vs. 6–8A in standard modules), saving 30% cabinet space.

- Advanced Diagnostics: LED indicators for power status (OK/FAULT), overload, and redundancy status; compatible with ABB System 800xA for remote monitoring.

- Wide Input Range: Accepts universal AC/DC inputs (85–264V AC/110–300V DC), eliminating the need for voltage converters.

- Energy Efficiency: 92% efficiency (vs. 85–88% in legacy models), reducing energy costs by 12% in 24/7 operations.

4. Application Fields and Cases

- Industries: Oil & gas (pump stations), water treatment (wastewater plants), automotive (assembly lines), and renewable energy (solar/wind farms).

- Use Case:

- Solar Farm Substation: The ABB PU516 powered 20 S800 I/O modules in a solar inverter array. Its redundant configuration and 92% efficiency minimized downtime during grid fluctuations, improving energy yield by 8% annually.

5. Competitor Comparison

Compared to standard power supply modules:

- Higher Redundancy Flexibility: Supports true parallel redundancy (vs. limited or no redundancy in 竞品), critical for 24/7 operations.

- Broader Input Range: Universal AC/DC compatibility (vs. AC-only or narrow DC ranges), reducing installation complexity.

- Integrated Protection: Built-in short-circuit/overload protection (vs. requiring external circuit breakers), lowering system costs by 15%.

ABB PU516

6. Selection Recommendations

- Power Requirements: Choose the PU516 (10A) for mid-sized systems; use PU515 (5A) for low-power setups or PU520 (20A) for high-density applications.

- Redundancy Needs: Opt for dual PU516 modules in safety-critical environments (e.g., oil refineries, medical equipment).

- Environment: Verify ambient temperature (max 60°C) and pollution degree (Degree 2) match site conditions; derate power at >40°C.

- Cost vs. Performance: Balances high power output and redundancy—cost-effective for applications needing continuous power (e.g., SCADA systems).

7. Precautions

-

Wiring: Use 10–16 AWG wires for input/output connections; separate power and signal cables to avoid EMI.

-

Redundancy Setup: Ensure identical PU516 modules (same firmware version) for parallel operation; maintain 50mm airflow clearance for cooling.

-

Voltage Validation: Confirm input voltage matches the module’s rating (AC/DC selector switch on the rear panel).

-

Maintenance: Replace modules every 10 years (per ABB lifecycle guidelines); clean dust from vents quarterly using compressed air.