Description

1. Product Description

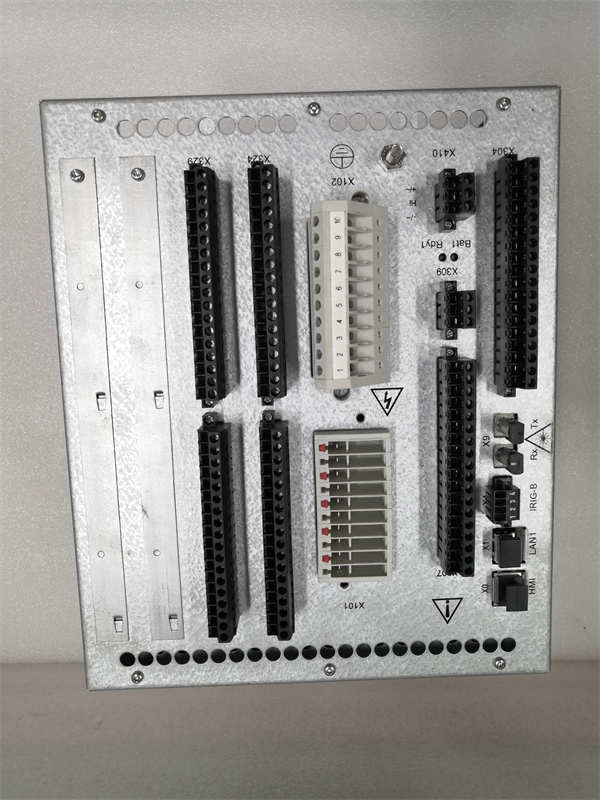

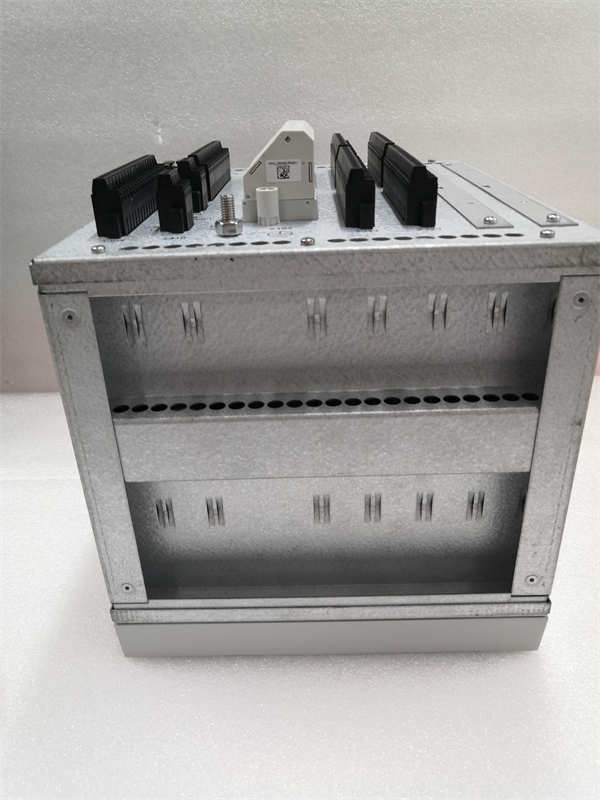

The ABB RET650 is a high-performance transformer protection module designed for utility substations and industrial applications, providing comprehensive protection, monitoring, and control for two-winding, three-winding, and autotransformers. As part of ABB’s Relion 650 series, the RET650 combines advanced protection functions with user-friendly configuration, ensuring reliability in critical electrical systems. Its core features include differential protection, overcurrent/overvoltage safeguards, frequency monitoring, and integrated control logic. The RET650 supports both customized and pre-configured solutions, allowing adaptation to specific application needs while minimizing parameter settings through ABB’s global base value concept. With Goose messaging for horizontal communication and a dynamic HMI with configurable LEDs, the RET650 enhances operational efficiency and safety.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Input | 110–240 V AC/DC (control power) |

| Current Input | 1 A or 5 A rated (selectable) |

| Protection Functions | Differential protection (2W/3W), overcurrent (phase/residual), over/under voltage, frequency protection |

| Communication Interfaces | IEC 61850-8-1, DNP 3.0 (RS-485/TCP), Modbus RTU/TCP |

| Digital I/O | Up to 30 binary inputs, 16 binary outputs |

| Analog Inputs | 20 analog inputs (current/voltage) |

| Operating Temperature | -40°C to +70°C (extended range for harsh environments) |

| Certifications | IEC 61850, EN 50263 (EMC), Low Voltage Directive (2006/95/EC) |

ABB RET650

3. Advantages and Characteristics

- Rapid Protection Response: The RET650 offers sub-cycle differential protection (<10 ms) for critical fault isolation, reducing downtime in power grids.

- Flexible Configuration: Customizable logic blocks and pre-configured templates enable adaptation to diverse applications (e.g., generation, transmission, industrial grids).

- Integrated Monitoring: Real-time metering, harmonic analysis, and tap changer control enhance asset health management.

- User-Friendly HMI: Dynamic three-color LEDs, configurable push-button shortcuts, and multilingual support simplify operation.

- Reliability: Certified to international standards, the module withstands harsh environments (e.g., vibration, temperature fluctuations) with a MTBF > 100,000 hours.

4. Application Fields and Cases

Industries: Energy (substations, power plants), manufacturing (industrial transformers), utilities (distribution networks).

Use Cases:

Use Cases:

- Utility Substation: A 110 kV substation in Europe deployed the RET650 for three-winding transformer protection, reducing fault clearing time by 30% compared to legacy systems.

- Industrial Campus: A steel plant in Asia used the RET650 to protect 20 MW transformers, integrating temperature monitoring and tap changer control for optimized efficiency.

5. Competitor Comparison

Compared to similar products, the RET650 stands out with:

- Single-IED Integration: Combines protection, control, and metering in one device, reducing panel space by 40%.

- Reduced Commissioning Time: Default parameters and automated testing (via RTXP test switch) cut setup time by 50% versus competitors.

- Global Compatibility: Supports multiple communication protocols (IEC 61850, DNP 3.0) and international standards, ensuring interoperability in global projects.

ABB RET650

6. Selection Suggestions

- Compatibility: Verify voltage/current ratings (1 A/5 A) and communication protocols against existing infrastructure.

- Application Complexity: Choose pre-configured models for standard grids or customized versions for specialized needs (e.g., OLTc control).

- Environment: Opt for extended temperature models (-40°C to +70°C) for outdoor/harsh environments.

- Budget: Balance feature requirements (e.g., advanced metering) with cost; pre-configured models offer lower upfront costs.

7. Precautions

-

Installation: Ensure CT/VT circuit integrity (verify polarity and burden) and proper grounding per IEC 61850 standards.

-

Commissioning: Use ABB’s commissioning tools (e.g., Relion Manager) for parameter validation and functional testing.

-

Maintenance: Schedule annual checks for firmware updates, contact wear, and environmental conditions (humidity, dust).

-

Safety: Disconnect power before wiring changes; follow lockout-tagout procedures during maintenance.