Description

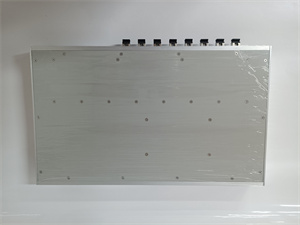

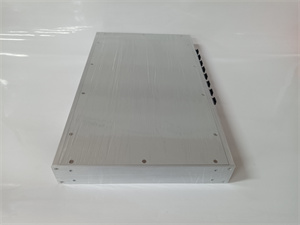

Product Description: GE ACC-5595-208 350-805595-208N

The GE ACC-5595-208 350-805595-208N is a high-performance communication module designed for industrial automation systems, specifically engineered to integrate with GE’s Series 90-70 and 90-30 PLC platforms. This module serves as a critical interface for seamless data exchange between controllers, remote I/O devices, and supervisory systems, enabling real-time monitoring and control in complex industrial environments. With robust connectivity features and compatibility with multiple protocols (e.g., Ethernet/IP, Modbus TCP), the ACC-5595-208 350-805595-208N ensures reliable communication in harsh industrial settings, making it ideal for applications requiring high uptime and precision.

Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 VDC (±10%) |

| Current | 150 mA (max) |

| Interface | Ethernet (10/100 Mbps), RS-485 (Modbus RTU) |

| Protocol Support | Ethernet/IP, Modbus TCP/RTU, DF1 |

| Compatibility | GE Series 90-70, 90-30 PLCs |

| Dimensions | 100 mm (W) × 150 mm (H) × 50 mm (D) |

| Operating Temperature | -40°C to +70°C (industrial grade) |

ACC-5595-208 350-805595-208N

Advantages and Features

- Dual Communication Redundancy:

The module supports redundant Ethernet connections, minimizing downtime and ensuring continuous operation in mission-critical systems. - Multi-Protocol Flexibility:

Compatible with industry-standard protocols (Ethernet/IP, Modbus), it integrates seamlessly with third-party devices and legacy systems. - High Reliability:

Built with industrial-grade components, it withstands extreme temperatures, vibrations, and electromagnetic interference (EMI). - Easy Integration:

Plug-and-play design reduces installation time, while intuitive configuration software (Proficy Machine Edition) simplifies setup.

Case Study: A manufacturing plant reduced commissioning time by 30% using the ACC-5595-208 350-805595-208N for its modular production line.

Application Areas and Use Cases

- Industry Sectors: Manufacturing, energy (oil/gas, power generation), water treatment, and automotive.

- 典型应用场景:

- Machine-to-machine (M2M) communication in smart factories.

- Remote monitoring of distributed I/O in oil refineries.

- SCADA integration for centralized control in power plants.

- 案例: A global energy company deployed the GE ACC-5595-208 350-805595-208N to connect 50+ remote pump stations, achieving 99.9% data transmission reliability and reducing maintenance costs by 25%.

Competitor Comparison

Compared to similar modules, the ACC-5595-208 350-805595-208N offers:

- Superior Protocol Support: Native integration with both Ethernet/IP and Modbus, whereas many alternatives require additional adapters.

- Lower Power Consumption: 150 mA (vs. 200–250 mA for 竞品), ideal for energy-efficient systems.

- Longer Lifecycle: Backed by GE’s industrial-grade design (10+ years of service in harsh environments).

ACC-5595-208 350-805595-208N

Selection Recommendations

- Compatibility: Ensure compatibility with your PLC platform (GE Series 90-70/30).

- Environment: Verify temperature and EMI requirements match your installation site.

- Scalability: Choose this module for systems needing future expansion (supports up to 128 nodes per network).

- Budget: Balance upfront costs with long-term reliability (lower maintenance vs. cheaper alternatives).

Precautions

- Installation: Follow ESD (electrostatic discharge) protection guidelines; use shielded cables for Ethernet/RS-485 connections.

- Maintenance: Schedule quarterly firmware updates via GE’s Proficy software to address security patches.

- Safety: Disconnect power before replacing the module; ensure compliance with IEC 61131-2 safety standards.