Description

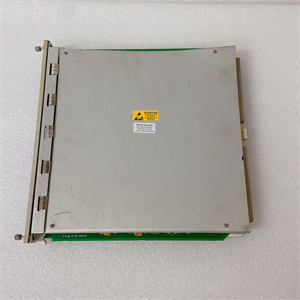

BENTLY NEVADA 125680-01 Proximitor I/O Module

1. Product Description

The BENTLY NEVADA 125680-01 is a 4-channel Proximitor I/O Module designed for integration with the 3500 Series Monitoring System, providing real-time vibration and displacement monitoring for rotating machinery. This module accepts inputs from eddy current sensors, delivering high-precision measurements for critical parameters like radial vibration, axial displacement, and eccentricity. With user-programmable alarm thresholds and dual-channel redundancy, it enables predictive maintenance and safeguards against equipment failures in industrial environments.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Model | 125680-01 |

| Input Type | Eddy current sensors |

| Power Supply | 24 VDC ±10% (external) |

| Channels | 4 (dual-channel configurable) |

| Measurement Accuracy | ±0.33% to ±1% of full scale |

| Frequency Range | 0–10 kHz |

| Compatibility | BENTLY 3500 Rack, 3300 Proximitors |

| Dimensions | 241 mm × 24.4 mm × 99.1 mm (9.50” × 0.96” × 3.90”) |

| Weight | 0.8 kg (1.76 lb) |

| Operating Temperature | -30°C to +65°C |

3. Advantages and Features

- Multi-Channel Flexibility: Simultaneously monitors four independent parameters, reducing system complexity.

- High Precision: Ensures accurate gap and frequency measurements for early fault detection.

- Programmable Alarms: Customizable setpoints enable proactive maintenance planning.

- Rugged Design: Built for harsh environments with resistance to vibrations and extreme temperatures.

Case Study: A petrochemical plant reduced turbine downtime by 25% using the 125680-01 to monitor shaft vibrations and thermal expansion.

4. Application Fields and Case Studies

Industries:

- Power generation, oil and gas, manufacturing, and marine propulsion.

典型应用:

- Turbines, compressors, pumps, and steam turbines.

Case Study: A European power plant improved generator reliability by 20% by integrating the module to detect rotor misalignment and bearing wear.

5. Competitive Comparison

The BENTLY NEVADA 125680-01 distinguishes itself through:

- Dual-Channel Redundancy: Supports SIL-rated safety systems with redundant power options.

- Wide Temperature Range: Operates in extreme conditions (-30°C to +65°C), outperforming standard modules limited to 0°C–50°C.

- Internal Terminations: Simplifies installation with pre-integrated wiring, reducing setup time.

6. Selection Recommendations

- System Complexity: Ideal for multi-sensor applications requiring simultaneous vibration and displacement monitoring.

- Safety Requirements: Choose for critical machinery in SIL-rated environments.

- Compatibility: Ensure compatibility with BENTLY’s 3500 Rack and existing automation software.

7. Precautions

- Sensor Calibration: Recalibrate eddy current sensors every 6 months for optimal accuracy.

- Power Redundancy: Use dual power supplies in safety-critical systems (refer to Section 10.2 of the manual).

- Firmware Updates: Regularly update firmware to enhance functionality and security.

Shanxi Runsheng Import and Export Co., LTD. is your trusted partner for BENTLY NEVADA 125680-01 and automation spare parts. Visit www.rsmodules.com or contact us for sales and technical support.