Description

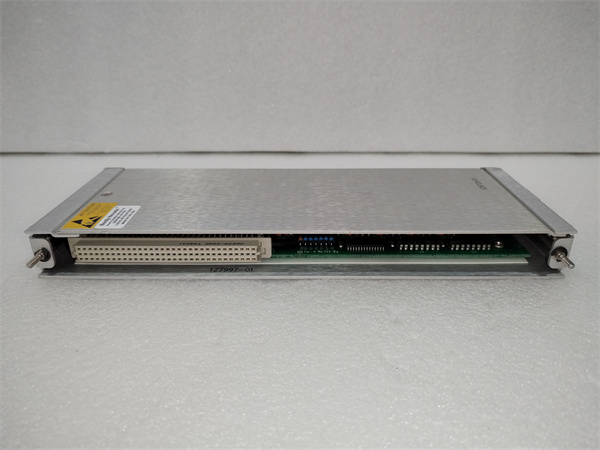

Bently Nevada 125720-01 4-Channel Relay I/O Module

1. Product Description

The Bently Nevada 125720-01 is a high-performance 4-channel relay I/O module designed for industrial automation and machinery protection systems. As part of the 3500 Series, it integrates seamlessly with Bently Nevada’s condition monitoring platforms, providing real-time control and alarm activation for rotating equipment such as turbines, compressors, and pumps. The module supports proprietary communication protocols like TDXnet and DDIX, enabling secure data exchange between the 3500 rack and control systems. Its compact design and slot-flexible installation (any slot to the right of the rack interface module) make it ideal for retrofitting or expanding existing setups.

The Bently Nevada 125720-01 is a high-performance 4-channel relay I/O module designed for industrial automation and machinery protection systems. As part of the 3500 Series, it integrates seamlessly with Bently Nevada’s condition monitoring platforms, providing real-time control and alarm activation for rotating equipment such as turbines, compressors, and pumps. The module supports proprietary communication protocols like TDXnet and DDIX, enabling secure data exchange between the 3500 rack and control systems. Its compact design and slot-flexible installation (any slot to the right of the rack interface module) make it ideal for retrofitting or expanding existing setups.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | 4-Channel Relay Output Module |

| Compatibility | Bently Nevada 3500 Series Racks |

| Channels | 4 independent relay outputs |

| Communication Protocols | TDXnet, DDIX (proprietary) |

| Power Supply | 24 VDC (via system rack) |

| Relay Ratings | 30 VDC/5 A resistive load |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 241 mm (H) × 24.4 mm (W) × 99.1 mm (D) |

| Weight | 0.4 kg |

Bently 125720-01

3. Advantages and Features

- Flexible Programming: Each relay output supports independent voting logic (AND/OR) for custom alarm thresholds, enhancing system adaptability.

- Robust Design: Built to withstand harsh industrial environments with a wide temperature range and 95% humidity tolerance.

- Modular Scalability: Multiple modules can be added to expand relay capacity, aligning with evolving operational needs.

- Rack Integration: Ensures seamless synchronization with 3500 Series racks, reducing setup complexity.

- Safety-Critical Functionality: Drives “Not OK” relays for shutdowns in critical scenarios like module removal or key switch changes.

4. Application Fields and Case Studies

- Energy: Monitors steam turbines in power plants, triggering shutdowns during 异常 vibration or temperature spikes.

- Oil & Gas: Controls compressor protection systems, activating alarms for bearing failures.

- Manufacturing: Manages conveyor systems in automotive plants, ensuring safety interlocks and synchronization.

- Case Study: A petrochemical plant reduced unplanned downtime by 25% using the 125720-01 to automate pump shutdowns based on vibration thresholds.

5. Competitor Comparison

Compared to similar relay modules, the Bently Nevada 125720-01 offers dual redundancy support and programmable alarm drive logic, reducing false triggers. Its slot-agnostic installation and proprietary protocol compatibility simplify integration with existing Bently Nevada systems, minimizing retrofitting costs.

Bently 125720-01

6. Selection Recommendations

- Compatibility: Ensure alignment with 3500 Series racks and TDXnet/DDIX protocols.

- Installation Slot: Verify slot availability to the right of the rack interface module.

- Power Requirements: Confirm 24 VDC supply compatibility.

- Functionality: Evaluate the need for independent relay logic vs. fixed-output modules.

7. Precautions

- Slot Placement: Install only in slots to the right of the rack interface module to avoid communication errors.

- Firmware Updates: Regularly update firmware to access advanced features and security patches.

- Redundancy: Consider dual-module setups for critical applications to ensure continuous operation.

- Safety Compliance: Follow NEC/EN standards for relay wiring and load ratings.