Description

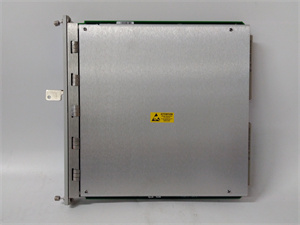

BENTLY NEVADA 3500/20 Transient Data Interface (TDI) Module

1. Product Description

The BENTLY NEVADA 3500/20 is a high-performance Transient Data Interface (TDI) module designed for real-time vibration monitoring and data acquisition in rotating machinery. As part of the BENTLY 3500 Series Monitoring System, it interfaces with sensors and external systems to enable continuous condition assessment, alarm triggering, and predictive maintenance. With a compact form factor and rugged construction, the 3500/20 supports seamless integration into industrial environments such as power plants, oil refineries, and manufacturing facilities.

The BENTLY NEVADA 3500/20 is a high-performance Transient Data Interface (TDI) module designed for real-time vibration monitoring and data acquisition in rotating machinery. As part of the BENTLY 3500 Series Monitoring System, it interfaces with sensors and external systems to enable continuous condition assessment, alarm triggering, and predictive maintenance. With a compact form factor and rugged construction, the 3500/20 supports seamless integration into industrial environments such as power plants, oil refineries, and manufacturing facilities.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/20 |

| Product Type | Transient Data Interface Module |

| Input Signal Range | -10 V DC to +10 V DC |

| Power Consumption | 7.7 W |

| Axis Power Supply | -24 V DC |

| Sensor Power Supply | -24 V DC |

| Weight | 0.82 kg (1.8 lb) |

| Dimensions | 241 mm × 24.4 mm × 242 mm (9.50 in × 0.96 in × 9.52 in) |

| Communication Protocols | RS-232/RS-422, Modbus (optional) |

| Compatibility | BENTLY 3500 Series racks and sensors |

Bently 3500/20

3. Advantages and Features

- Real-Time Data Acquisition: Captures transient events for vibration analysis, enabling proactive maintenance.

- Dual-Channel Design: Supports simultaneous monitoring of two independent vibration signals.

- Modular Flexibility: Easily expandable within the 3500 Series system for multi-machine setups.

- Rugged Performance: Operates reliably in harsh conditions with EMI/EMC protection.

- User-Friendly Configuration: Web-based interface for parameter adjustment and firmware updates.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Power Generation: Steam turbines and generators.

- Oil & Gas: Pumps and compressors in offshore platforms.

- Manufacturing: Conveyor systems and rotating equipment.

Case Study: A U.S. power plant reduced turbine downtime by 25% using the 3500/20 to detect early-stage bearing wear through real-time vibration analysis.

5. Competitor Comparison

- Enhanced Signal Resolution: Offers higher sampling rates than basic vibration modules.

- Simplified Integration: Requires minimal setup compared to complex third-party solutions.

- Cost-Effective Redundancy: Optional dual-channel configuration provides redundancy at a lower cost than standalone systems.

Bently 3500/20

6. Selection Recommendations

- Rack Compatibility: Ensure compatibility with 3500 Series racks (full-size or mini).

- Redundancy Needs: Opt for dual-channel models in critical applications.

- Communication Requirements: Verify Modbus or RS-422 compatibility with existing systems.

7. Precautions

- Proper Installation: Mount in a vibration-free environment away from direct sunlight.

- Power Stability: Use a regulated -24 V DC power supply to avoid voltage fluctuations.

- Firmware Updates: Regularly update firmware to access advanced features and bug fixes.

Shanxi Runsheng Import and Export Co., LTD. provides BENTLY NEVADA 3500/20 and comprehensive automation solutions. Visit www.rsmodules.com for technical support and product inquiries.