Description

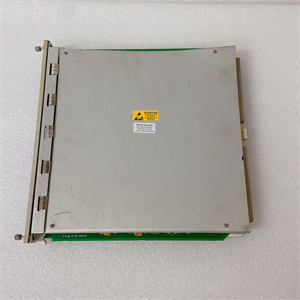

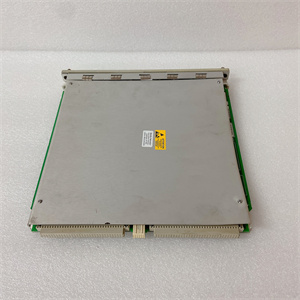

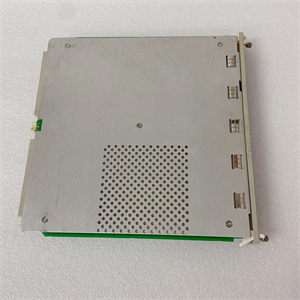

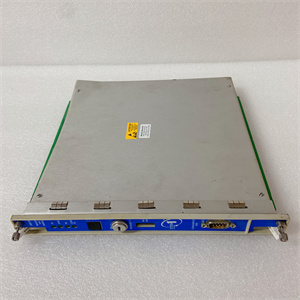

BENTLY NEVADA 3500/22M 138607-01 Transient Data Interface Module

1. Product Description

The BENTLY NEVADA 3500/22M 138607-01 is a high-performance transient data interface module designed for seamless integration with the 3500 Series Monitoring System. Serving as the bridge between machinery health data and advanced analytics software like System 1, it enables real-time acquisition, storage, and transmission of steady-state and transient vibration waveforms. This module combines the functionality of a 3500/20 Rack Interface Module (RIM) with enhanced data collection capabilities, supporting up to 16 channels of synchronous vibration, displacement, and velocity measurements. Ideal for critical rotating equipment in oil & gas, power generation, and manufacturing, the 3500/22M ensures proactive maintenance by delivering actionable insights into machinery performance.

The BENTLY NEVADA 3500/22M 138607-01 is a high-performance transient data interface module designed for seamless integration with the 3500 Series Monitoring System. Serving as the bridge between machinery health data and advanced analytics software like System 1, it enables real-time acquisition, storage, and transmission of steady-state and transient vibration waveforms. This module combines the functionality of a 3500/20 Rack Interface Module (RIM) with enhanced data collection capabilities, supporting up to 16 channels of synchronous vibration, displacement, and velocity measurements. Ideal for critical rotating equipment in oil & gas, power generation, and manufacturing, the 3500/22M ensures proactive maintenance by delivering actionable insights into machinery performance.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/22M 138607-01 |

| Function | Transient Data Interface Module |

| Compatibility | BENTLY 3500 Series Monitoring System |

| Data Acquisition Rate | Up to 20 kHz per channel |

| Communication | 10/100Base-T Ethernet, 100Base-FX (fiber-optic) |

| Power Supply | -24 VDC (via 3500 Rack) |

| Power Consumption | 10.5 W |

| Data Storage | Onboard memory for pre/post-alarm snapshots |

| LED Indicators | Status, communication, and error alerts |

| Physical Dimensions | 263 × 138 × 88 mm (10.35 × 5.43 × 3.46 in) |

| Weight | 0.82 kg (1.81 lbs) |

BENTLY 3500/22M 138607-01

3. Advantages and Features

- High-Speed Data Collection: Captures transient events (e.g., start-up/shutdown) with 20 kHz resolution for detailed waveform analysis.

- Dual-Functionality: Integrates RIM and data acquisition capabilities, reducing rack space and complexity.

- Flexible Connectivity: Supports Ethernet and fiber-optic links for remote monitoring and integration with SCADA systems.

- Predictive Maintenance: Enables early detection of machinery faults through continuous waveform analysis.

- Compliance: Meets API 670, CE, and SIL 2 safety standards for critical applications.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Oil & Gas: Compressors, pumps, and turbines.

- Power Generation: Steam and gas turbines.

- Manufacturing: High-speed rotating machinery.

Case Study: A petrochemical plant in the Middle East reduced unplanned downtime by 30% using the 3500/22M to monitor compressor vibrations. Early detection of rotor imbalance via transient data analysis allowed scheduled repairs, avoiding costly failures.

5. Competitor Comparison

- Superior Data Resolution: 20 kHz sampling rate outperforms legacy modules with 10 kHz limits.

- Integrated Design: Combines RIM and data acquisition in one module, reducing cabling and setup time compared to standalone solutions.

- Software Compatibility: Seamless integration with System 1 for advanced diagnostics, unlike generic third-party tools.

-

BENTLY 3500/22M 138607-01

6. Selection Recommendations

- System Compatibility: Ensure alignment with 3500 Series Racks and M-Series Monitors (e.g., 3500/42M).

- Data Requirements: Choose between Ethernet or fiber-optic connectivity based on plant network infrastructure.

- Expansion Needs: Pair with 3500/25-00 vibration monitors for comprehensive machinery health coverage.

7. Precautions

- Cabling: Use shielded Ethernet cables to minimize electromagnetic interference.

- Memory Management: Regularly archive transient data to prevent onboard memory overload.

- Firmware Updates: Keep the module’s firmware current for optimal performance and security.

Shanxi Runsheng Import and Export Co., LTD. offers BENTLY NEVADA 3500/22M 138607-01 and automation solutions. Visit www.rsmodules.com for technical support and product inquiries.