Description

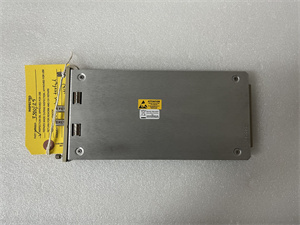

BENTLY NEVADA 3500/25 149369-01 Enhanced Keyphasor Module

1. Product Description

The BENTLY NEVADA 3500/25 149369-01 is a half-height, dual-channel module designed for the 3500 Machinery Monitoring System. It converts analog signals from proximity probes or magnetic pickups into digital keyphasor signals, indicating when a shaft’s keyphasor mark aligns with the transducer. This module is critical for precise rotational speed measurements, vibration analysis, and machinery protection in industries such as oil & gas, power generation, and manufacturing. Its enhanced features, including field-upgradeable firmware and advanced signal processing, ensure compatibility with modern and legacy systems.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/25 149369-01 |

| Channels | 2 (input/output pairs) |

| Input Signal Range | +0.8V to -21.0V (non-isolated) / +5V to -11V (isolated) |

| Input Impedance | ≥21.8 kΩ |

| Speed Range | 1–1,200,000 CPM (0.017–20 kHz) |

| Output Range | 1–99,999 CPM (0.017–1,667 Hz) |

| Power Supply | -24V DC (40 mA max per channel) |

| Power Consumption | 3.2W (typical) |

| Operating Temperature | -30°C to +65°C |

| Physical Dimensions | 119.9 mm × 24.4 mm × 256.5 mm |

| Weight | 0.34 kg |

Bently 3500/25 149369-01

3. Advantages and Features

- Dual-Channel Design: Simultaneously processes two keyphasor inputs for redundancy or multi-shaft applications.

- Enhanced Signal Processing: Converts multi-event-per-turn inputs into once-per-turn signals for accurate timing.

- Field-Upgradeable Firmware: Allows software updates without replacing hardware.

- Hazardous Area Compliance: Meets ATEX/IECEx certifications for use in explosive environments.

- Backward Compatibility: Replaces legacy modules (e.g., 125792-01) while maintaining system integrity.

Case Study: A petrochemical plant reduced compressor misalignment incidents by 30% using the 3500/25 to synchronize vibration analysis with shaft position data.

4. Application Fields and Case Studies

Industries:

- Oil & gas, power generation, manufacturing, and marine propulsion.

典型应用:

- Turbines, compressors, pumps, and rotating machinery.

Case Study: A power plant improved generator efficiency by 15% by using the module to synchronize steam turbine speed with grid frequency.

5. Competitive Comparison

The BENTLY NEVADA 3500/25 outperforms alternatives with:

- Dual-Channel Redundancy: Supports TMR (Triple Modular Redundancy) systems.

- Wide Speed Range: Handles high-speed machinery up to 20 kHz.

- Integrated Diagnostics: Provides asset health data for predictive maintenance.

-

Bently 3500/25 149369-01

6. Selection Recommendations

- Multi-Shaft Systems: Opt for paired configurations (up to 8 channels).

- Safety-Critical Environments: Choose isolated I/O modules for hazardous areas.

- Legacy Upgrades: Ensure compatibility with existing 3500 racks and software.

7. Precautions

- Voltage Compliance: Use isolated I/O modules for magnetic pickup applications requiring external power.

- Phase Shift Awareness: Isolated modules introduce slight phase shifts; verify alignment with system tolerances.

- Firmware Updates: Regularly update firmware for optimal performance.

Shanxi Runsheng Import and Export Co., LTD. is your trusted partner for BENTLY NEVADA 3500/25 149369-01 and automation spare parts. Visit www.rsmodules.com or contact us for sales and technical support.