Description

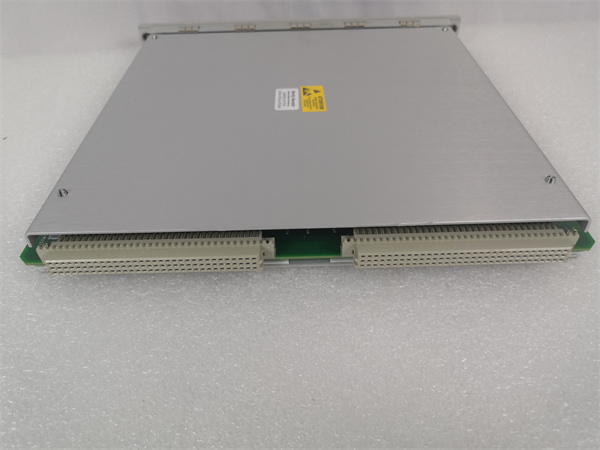

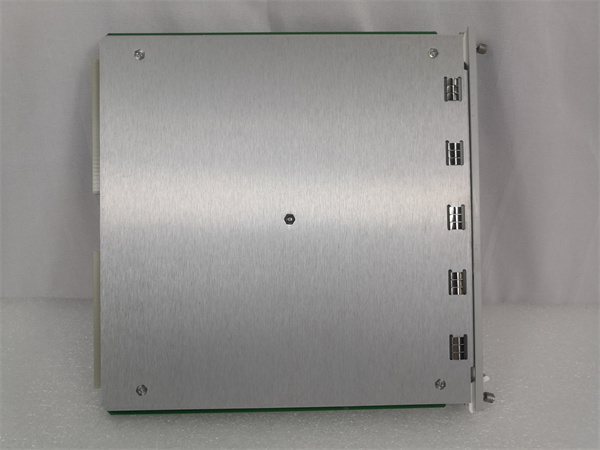

BENTLY NEVADA 3500/33 176449-03 Vibration Monitoring Module

1. Product Description

The BENTLY NEVADA 3500/33 176449-03 is a dual-channel vibration monitoring module designed for rotating machinery health analysis in industrial environments. As part of the BENTLY 3500 Series Machinery Health Monitoring System, this module provides real-time vibration amplitude and phase measurements, enabling predictive maintenance and compliance with API 670 and ISO 10816 standards. It supports proximity probes or velocity sensors to detect shaft vibration, eccentricity, and axial movement in turbines, compressors, and pumps. The 3500/33 integrates seamlessly with the 3500 Rack Configuration Software, offering configurable alarm thresholds and trending capabilities to prevent equipment failures.

The BENTLY NEVADA 3500/33 176449-03 is a dual-channel vibration monitoring module designed for rotating machinery health analysis in industrial environments. As part of the BENTLY 3500 Series Machinery Health Monitoring System, this module provides real-time vibration amplitude and phase measurements, enabling predictive maintenance and compliance with API 670 and ISO 10816 standards. It supports proximity probes or velocity sensors to detect shaft vibration, eccentricity, and axial movement in turbines, compressors, and pumps. The 3500/33 integrates seamlessly with the 3500 Rack Configuration Software, offering configurable alarm thresholds and trending capabilities to prevent equipment failures.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 3500/33 176449-03 |

| Input Type | Proximity probe (8–12 VDC) or velocity sensor (AC) |

| Channels | Dual (independent monitoring) |

| Frequency Range | 0.5–10,000 Hz (proximity), 2–1000 Hz (velocity) |

| Outputs | 4–20 mA analog, relay contacts (5 A max) |

| Power Supply | 100–240 VAC, 50/60 Hz (via 3500 Rack) |

| Dynamic Range | ±1000 μm (proximity), ±100 mm/s (velocity) |

| Resolution | 0.1% of full scale |

| Operating Temperature | -30°C to +65°C |

| Dimensions | 241 mm × 24 mm × 254 mm |

| Weight | 0.7 kg |

BENTLY 3500/33

3. Advantages and Features

- Dual-Channel Redundancy: Simultaneous monitoring of two critical vibration parameters (e.g., X and Y directions).

- API/ISO Compliance: Direct support for API 670 safety systems and ISO 10816 vibration severity guidelines.

- Adaptive Filtering: Advanced signal processing reduces noise interference for accurate measurements.

- User-Configurable: Customizable alarm levels and analog outputs via BENTLY’s 3500 Software.

- Self-Diagnostics: Front-panel LEDs indicate sensor faults or module errors.

4. Application Areas and Use Cases

Industry Applications:

Industry Applications:

- Oil & Gas: Centrifugal pumps, gas turbines.

- Power Generation: Steam turbines, generators.

- Water Treatment: High-speed pumps.

Case Study: A European power plant reduced vibration-related downtime by 35% using the 3500/33 to monitor a steam turbine. Early detection of rotor imbalance allowed proactive maintenance, avoiding costly repairs.

5. Competitor Comparison

- Multi-Parameter Support: Simultaneous amplitude and phase monitoring in a single module, unlike some competitors requiring separate units.

- Software Integration: Native compatibility with BENTLY’s 3500 Series software for unified data management.

- Sensor Flexibility: Supports both proximity and velocity sensors, offering broader application coverage.

BENTLY 3500/33

6. Selection Recommendations

- Sensor Type: Choose proximity probes for shaft displacement or velocity sensors for casing vibration.

- Rack Expansion: Ensure 3500 Rack slots are available for additional modules (e.g., temperature or process variables).

- Alarm Configuration: Adjust thresholds based on ISO 10816 vibration severity classes.

7. Precautions

- Probe Installation: Maintain precise probe alignment (<±0.05 mm) to avoid measurement errors.

- Grounding: Isolate signal cables from power lines to prevent EMI.

- Calibration: Verify sensor linearity annually using BENTLY’s 3500/05 Calibration Interface.