Description

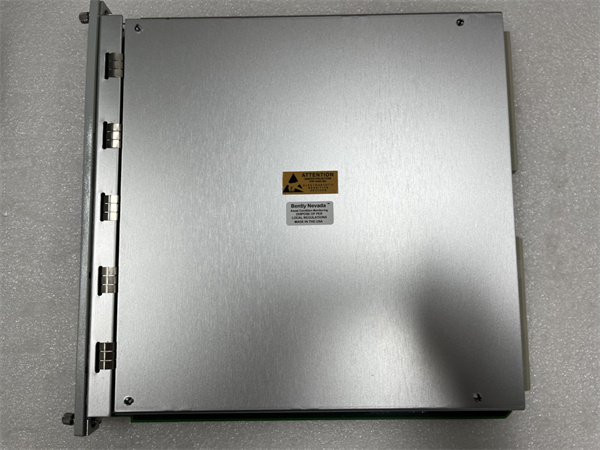

1. Product Description

2. Product Specifications

| Parameter | Details |

|---|---|

| Model | 3500/92 |

| Brand | BENTLY |

| Type | Keyphasor and Speed Monitor Module |

| Input Voltage | 18–30 VDC (nominal 24 VDC) |

| Frequency Range | 0.1 Hz to 10 kHz (speed: 0.1 RPM to 1,000,000 RPM) |

| Signal Inputs | Two channels for proximity probes or tachometer signals |

| Output Signals | Analog (4–20 mA, 0–10 VDC) and digital (TTL/CMOS) |

| Resolution | 0.1 RPM (dependent on input signal quality) |

| Compatibility | BENTLY 3500 Machinery Protection System |

| Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Mounting | Rack-mounted within 3500 Chassis |

| Certifications | CE, CSA, ATEX (for hazardous environments) |

BENTLY 3500/92

3. Advantages and Features

4. Application Areas and Use Cases

5. Competitive Comparison

In comparison to similar speed monitoring solutions, the BENTLY 3500/92 offers superior multi-probe compatibility and diagnostic depth, ensuring seamless integration with the 3500 system’s comprehensive monitoring architecture. Its dual-channel redundancy and advanced signal conditioning reduce reliance on external components, simplifying system design while enhancing reliability. Unlike many alternatives, it provides both analog and digital outputs, catering to a wide range of control and data acquisition needs.

BENTLY 3500/92

6. Selection Recommendations

- System Integration: Ensure compatibility with your existing 3500 chassis and software to leverage full diagnostic and communication capabilities.

- Signal Requirements: Determine if your machinery requires single or dual-channel monitoring, and verify probe type compatibility (proximity vs. tachometer).

- Environmental Demands: Confirm the module’s temperature and vibration resistance meet your site’s conditions, especially for high-speed or high-vibration applications.

- Data Output Needs: Assess whether analog, digital, or both output types are necessary for your control system or data analytics platform.

7. Precautions

- Installation: Follow BENTLY’s guidelines for proper rack mounting and wiring to ensure signal integrity and prevent electromagnetic interference (EMI).

- Calibration: Use certified calibration tools to verify frequency response and signal accuracy during commissioning and periodic maintenance.

- Probe Alignment: Ensure proximity probes are correctly positioned and calibrated to avoid measurement errors caused by incorrect air gap or misalignment.

- Redundancy Testing: Regularly test dual-channel functionality to ensure failover mechanisms operate correctly in the event of a probe or cable failure.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.