Description

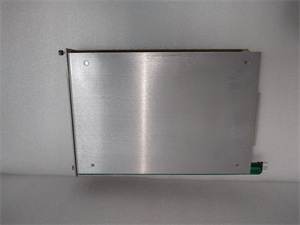

BENTLY 85515-02 Turbine Overspeed Protection Module

1. Product Description

The BENTLY 85515-02 is a high-reliability overspeed protection module designed for critical rotating machinery, such as gas turbines and compressors. As part of the BENTLY 3500 modular monitoring system, it provides real-time speed measurement, alarm triggering, and shutdown capabilities to prevent catastrophic overspeed events. The module supports dual-channel inputs for redundancy, hot-swap functionality for maintenance flexibility, and integrates seamlessly with BENTLY’s System 1 software for advanced condition analysis. Its compact design and rugged construction make it suitable for harsh industrial environments, ensuring continuous operation in power generation, oil & gas, and manufacturing sectors.

The BENTLY 85515-02 is a high-reliability overspeed protection module designed for critical rotating machinery, such as gas turbines and compressors. As part of the BENTLY 3500 modular monitoring system, it provides real-time speed measurement, alarm triggering, and shutdown capabilities to prevent catastrophic overspeed events. The module supports dual-channel inputs for redundancy, hot-swap functionality for maintenance flexibility, and integrates seamlessly with BENTLY’s System 1 software for advanced condition analysis. Its compact design and rugged construction make it suitable for harsh industrial environments, ensuring continuous operation in power generation, oil & gas, and manufacturing sectors.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC ±10% (for module operation) |

| Power Supply | 20–34 VDC or 90–140 VDC (external input) |

| Channels | Dual-channel (A and B) for redundant protection |

| Speed Range | 0–100,000 RPM (configurable) |

| Alarm Outputs | 4 solid-state relays (2 per channel) |

| Communication | Modbus RTU (RS-485) for integration with PLC/DCS |

| Operating Temperature | -40°C to +70°C |

| Compatibility | BENTLY 3500 racks, System 1 software |

BENTLY 85515-02

3. Advantages and Features

- Dual-Channel Redundancy: Ensures fail-safe operation by comparing two independent speed signals.

- Hot-Swap Capability: Allows replacement without system downtime, reducing maintenance costs.

- Precision Speed Monitoring: Uses advanced algorithms to detect overspeed within milliseconds.

- Customizable Alarms: Configurable setpoints for pre-trip warnings and emergency shutdowns.

- Wide Voltage Range: Supports both low and high DC input voltages for versatile applications.

4. Application Fields and Case Studies

- Energy: Protecting gas turbines in power plants during load fluctuations.

- Oil & Gas: Monitoring compressor trains in offshore platforms.

- Manufacturing: Preventing overspeed in high-speed rotating equipment.

Case Study: A petrochemical plant avoided $2M in potential damages by deploying the 85515-02 to trigger emergency shutdowns during unexpected speed surges in their centrifugal compressors.

BENTLY 85515-02

5. Competitor Comparison

The 85515-02 outperforms alternatives with:

The 85515-02 outperforms alternatives with:

- Built-in redundancy for SIL 2 compliance, reducing the need for external safety modules.

- Faster response time (≤10 ms) compared to legacy overspeed systems.

- Compatibility with BENTLY’s comprehensive System 1 analytics suite for predictive maintenance.

6. Selection Recommendations

- System Integration: Pair with BENTLY 3500 racks for unified machinery health monitoring.

- Safety Requirements: Choose the dual-channel version for applications requiring SIL 2 certification.

- Expansion Needs: Ensure rack space for future additions like vibration or temperature modules.

7. Precautions

- Power Stability: Use a filtered power supply to avoid voltage spikes.

- Sensor Calibration: Verify proximity probe alignment and signal integrity before commissioning.

- Firmware Updates: Regularly update to access new features and security patches.