Description

1. Product Description

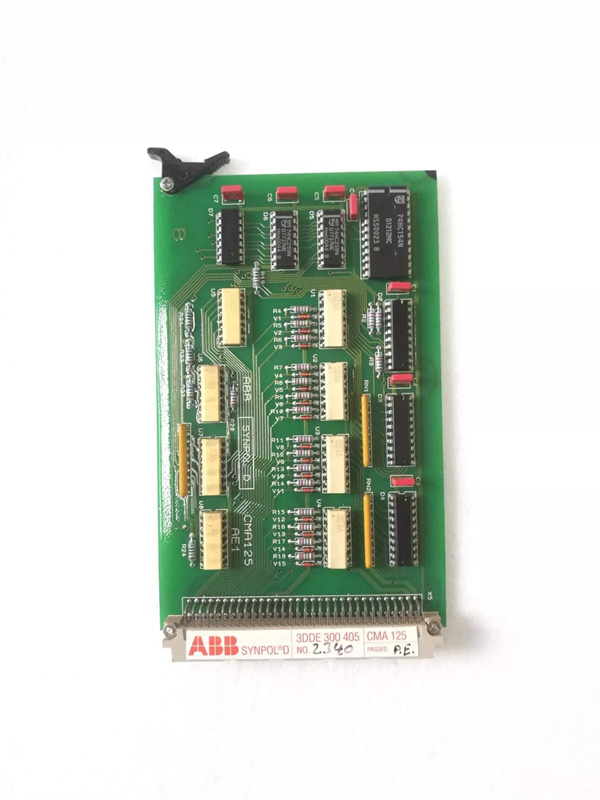

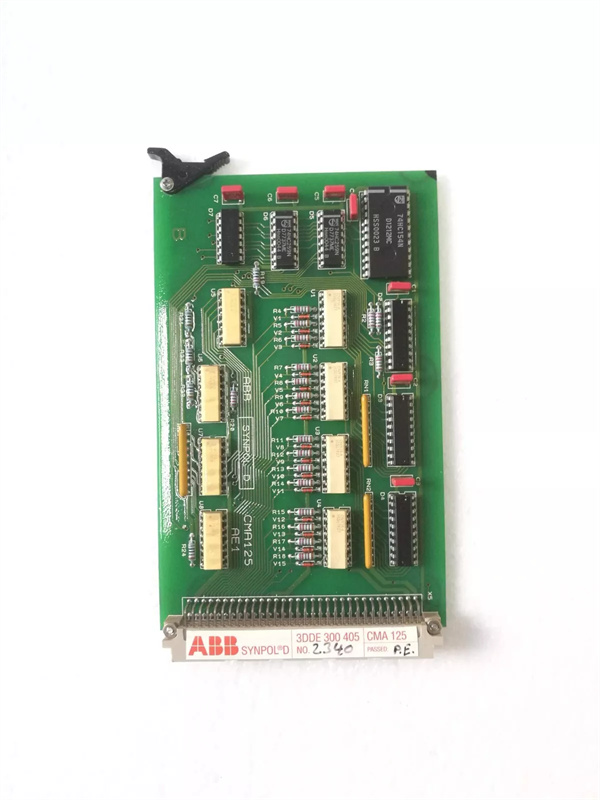

The ABB CMA125 3DDE300405 is a high-performance motor control module designed for industrial automation systems, specializing in precise motor management and power distribution. Part of ABB’s CMA (Contactor Motor Advanced) series, this module combines robust protection, energy efficiency, and intelligent control for seamless integration in manufacturing, energy, and process industries. The 3DDE300405 variant features advanced safety mechanisms, modular design, and compatibility with ABB’s automation platforms (e.g., AC500, AC800M), ensuring reliable operation in harsh environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | CMA125 3DDE300405 |

| Brand | ABB |

| Rated Current | 125 A (3-phase, 400 V AC) |

| Voltage | 24–250 V AC (control circuit) |

| Protection Features | Overload, short-circuit, phase loss |

| Interface | Profibus DP, Modbus RTU, Digital I/O (8x) |

| Control Type | Soft start/stop, direct-on-line (DOL) |

| Mounting | DIN rail (35 mm) or panel-mounted |

| Operating Temperature | -20°C to +55°C |

| Dimensions (W×H×D) | 150 mm × 200 mm × 120 mm |

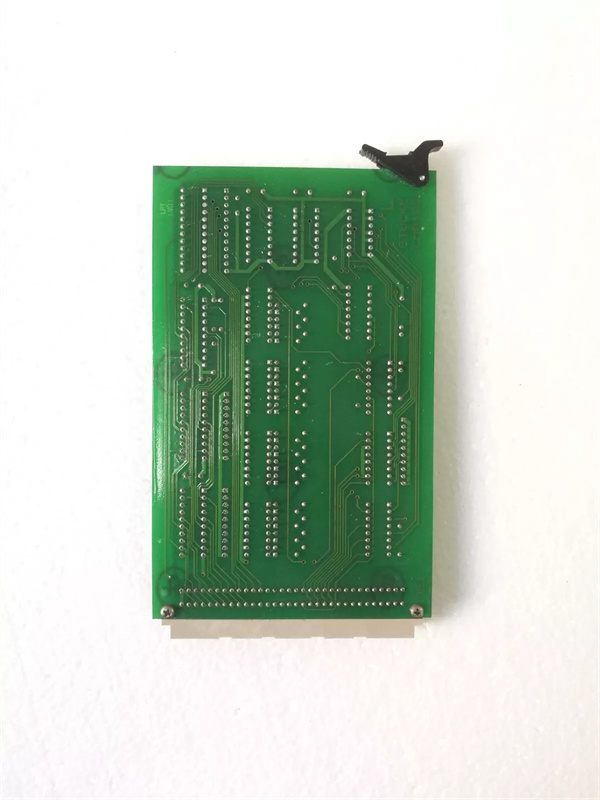

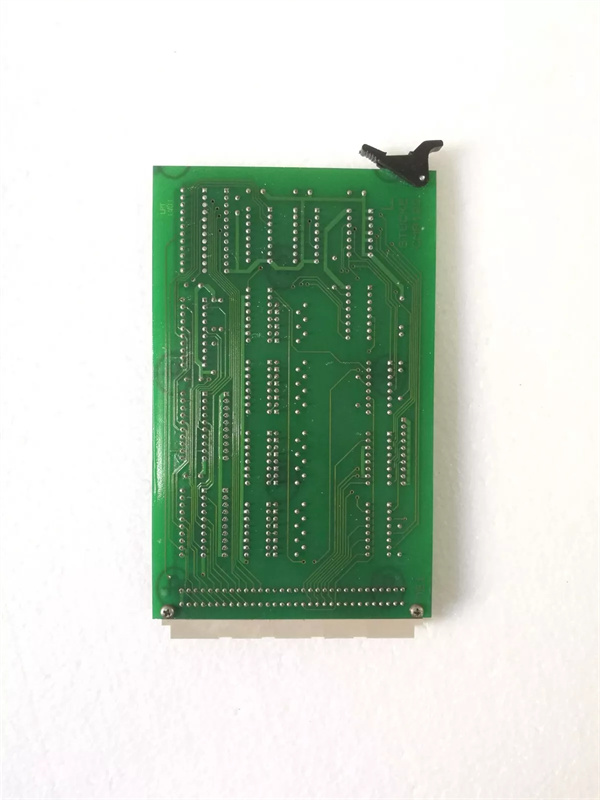

CMA125 3DDE300405

3. Advantages and Features

- Intelligent Motor Control: Adjustable acceleration/deceleration ramps reduce mechanical stress on motors, extending lifespan.

- Energy Efficiency: Built-in power monitoring (±1% accuracy) and low standby power (<5 W).

- Modular Design: Expandable with ABB’s accessories (e.g., communication modules, thermal sensors).

- Safety Compliance: Certified to IEC 60947-4-1, UL 508, and CE, with built-in emergency stop (STO) functionality.

4. Application Areas and Use Cases

Industries: Manufacturing (conveyor systems), water/wastewater (pump control), oil/gas (compressor management), and HVAC.

Use Case: A textile factory in India integrated the CMA125 3DDE300405 for spindle motor control. The module’s soft-start capability reduced inrush current by 40%, eliminating voltage dips and cutting downtime related to motor failures by 25%.

Use Case: A textile factory in India integrated the CMA125 3DDE300405 for spindle motor control. The module’s soft-start capability reduced inrush current by 40%, eliminating voltage dips and cutting downtime related to motor failures by 25%.

5. Competitive Comparison

Compared to similar motor control modules (e.g., Siemens 3RW44, Schneider ATV320):

- Compact Design: 20% smaller than Siemens equivalent while offering higher current capacity.

- Multi-Protocol Support: Native integration with ABB’s proprietary systems plus open protocols (Modbus, Profibus).

- Cost Efficiency: 10–15% lower total cost of ownership (TCO) due to reduced installation and maintenance needs.

CMA125 3DDE300405

6. Selection Recommendations

- Current Rating: Ensure 125 A matches your motor’s full-load current (FLC).

- Environment: Verify temperature/humidity (5–95% non-condensing) and vibration (IEC 60068-2-6) requirements.

- Communication: Choose optional modules (e.g., Ethernet/IP) for IoT-enabled monitoring.

- Redundancy: Pair with ABB’s redundant control systems (e.g., AC800M) for critical applications.

7. Precautions

-

Installation: Follow torque specifications (screw terminals: 4–6 N·m) and wire sizing (≥6 mm² for power cables).

-

Maintenance: Annual checks for contact wear (replace if pitting >1 mm); clean vents with dry air (≤2 bar).

-

Software: Use ABB’s DriveWindow LT for configuration and firmware updates (latest version: 4.2.1).